Mixing barrel with adjustable radiation effect

A heat dissipation effect and mixing tank technology, applied in the direction of mixer accessories, dissolving, mixing machines, etc., can solve the problems of poor safety, poor versatility, and poor structure compactness, and achieve the effects of good versatility, light weight, and reduced inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

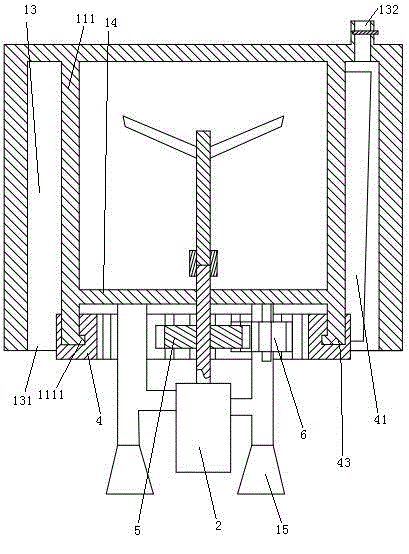

[0029] Embodiment two, see image 3 , The difference with the first embodiment is: the stirring motor 2, the driving gear 6 and the intermediate gear 5 are all arranged on the lower end wall 14 of the barrel 1, and the stirring motor 2 is fixed on the supporting feet 15. A lower end of the inner wall 111 is provided with an inner flange 1111 . The section of the chute 43 is "L" shape. The driving ring 4 is suspended and slidably connected to the lower end of the inner side wall 111 through the inner flange 1111 and the chute 43 . The air outlet 131 is formed by completely opening the lower end of the cavity 13 . The air inlet 132 is provided on the upper end of the cavity 13 .

Embodiment 3

[0030] Embodiment three, see Figure 4 , the difference with the first embodiment is: the stirring motor is a DC brushless motor. The stirring motor also includes a casing 23 , an outer rotor 24 , an inner rotor 25 and a controller 26 . The outer rotor 24 is fixed to the casing 23 . An accommodating chamber 231 and an air inlet channel 232 are disposed in the upper end of the housing 23 . The controller 26 is accommodated in the accommodation cavity 231 . The air inlet channel 232 passes through the accommodating cavity 231 . The inlet 2321 of the air inlet channel is disposed on the upper surface of the casing 23 . The lower end of the casing 23 is provided with an air outlet channel 233 . The outlet 2331 of the air outlet channel is located on the peripheral surface of the casing 23 and faces downward. The power output shaft 21 is rotatably connected to the lower end of the casing 23 through a bearing 27 . The inner rotor 25 is located within the outer rotor 24 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com