Analog flue gas mixing device based on high temperature humidity generator

A technology of humidity generator and simulated flue gas, which is applied in the direction of gas and gas/steam mixing, mixer, mixing method, etc., which can solve the inconsistency of flue gas temperature, humidity and sulfur content, failing to meet the requirements of flue gas simulation, Correct problems such as large changes in the environment of the humidity probe to achieve the effects of avoiding mutual interference or influence, fast response speed, and small fluctuations in accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

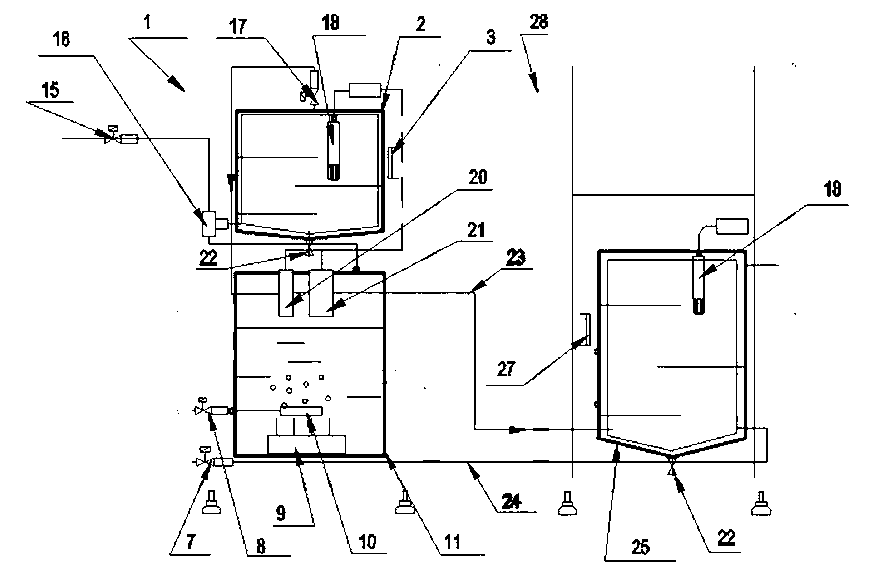

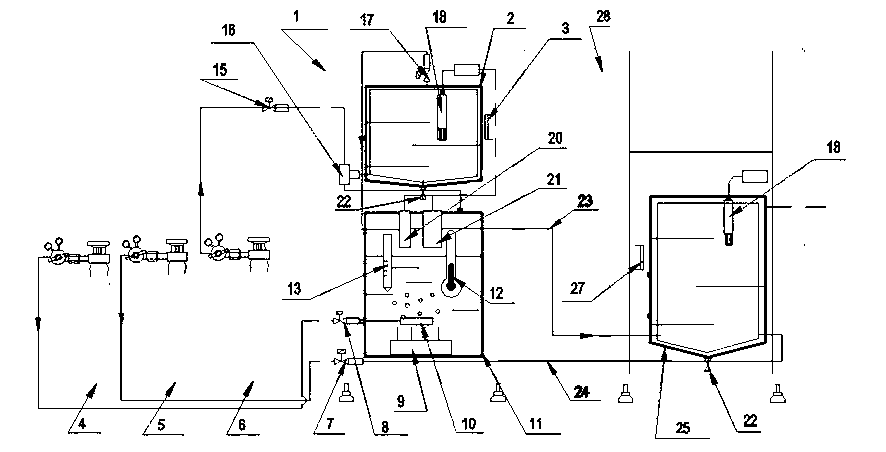

[0030] Such as figure 1 As shown, the simulated flue gas mixing device based on the high-temperature humidity generator of this patent is mainly divided into two parts: the high-temperature standard humidity generating device 1 and the flue gas mixing device 28, including the gas storage tank 2, the standard gas flow meter 7, Moisture gas flow meter 8, bubbler 10, constant temperature water tank 11, dry gas flow meter 15, tee joint 16, mixed moisture flow meter 17, small detection chamber 20, medium detection chamber 21, mixed moisture pipeline 23 , standard gas heating pipeline 24, mixed gas tank 25, and dew point meter 18; the wet gas flowmeter 8 is connected to the foamer 10 arranged inside the constant temperature water tank 11, and the three-way joint 16 is respectively connected to the constant temperature water tank 11 outlet and the dry gas flow rate The meter 15 is connected to the inlet of the gas storage tank 2, and the outlet of the gas storage tank 2 is connected ...

Embodiment 2

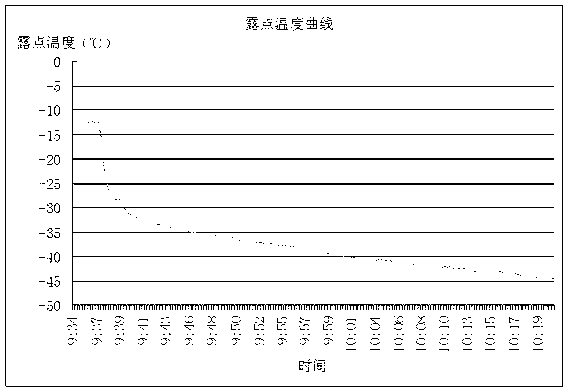

[0071] The performance test of the high temperature standard humidity generating device 1 adopts the CEMS DAS laboratory test software developed by Nanjing Essen Environmental Technology Co., Ltd. The test steps are as follows:

[0072] step 1 : Set the test environment: indoor, no vibration, room temperature 25°C;

[0073] The parameters of the high temperature standard humidity generating device 1 are set as follows:

[0074] The temperature control meter of the constant temperature water tank is set at 48°C

[0075] The temperature control meter of the detection chamber is set at 54°C

[0076] Sampling interval: 15s

[0077] step 2 : Reliably connect the wet gas tank 4 and the dry gas tank 6 to the wet gas flowmeter 8 and the dry gas flowmeter 15 interfaces in the high temperature standard humidity generating device 1 respectively. The technical indicators of the above two gases are as follows:

[0078] 1) Humidity: Compressed air: O 2 : 21%; ...

Embodiment 3

[0102] The actual usage test of the simulated flue gas mixing device based on the high-temperature humidity generator of this patent is as follows:

[0103] The temperature of the calibration gas heating pipeline 24 is maintained at 150°C, and the temperature inside the mixed gas tank 25 is set to not be lower than 120°C. Use a multi-component analyzer to measure SO at the gas outlet of the high-temperature mixed gas tank 25 2 concentration and humidity to verify the loss of SO2 and the stability of the humidity of the mixed gas during the gas mixing process, see Figure 9 (Table 1), Figure 10 (Table 2).

[0104] Testing requirements:

[0105] 1) Inlet humidity: 10.5Vol%, 5.5Vol%, respectively.

[0106] 2) Select the standard gas to simulate SO 2 Pollution gas, the main component is SO 2 The concentration is 1000PPM, the rest is N 2 .

[0107] 3) There are two sets of test settings, and the test temperatures are 100°C and 150°C respectively.

[0108] 4) Mix the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com