Module combined bag type dust remover and loading and transporting method thereof

A technology of bag filter and module combination, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., which can solve problems such as heavy assembly, hoisting and welding workload, difficult installation quality control, and long installation cycle. , to achieve the effect of shortening the construction period, reducing installation costs, and improving installation accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

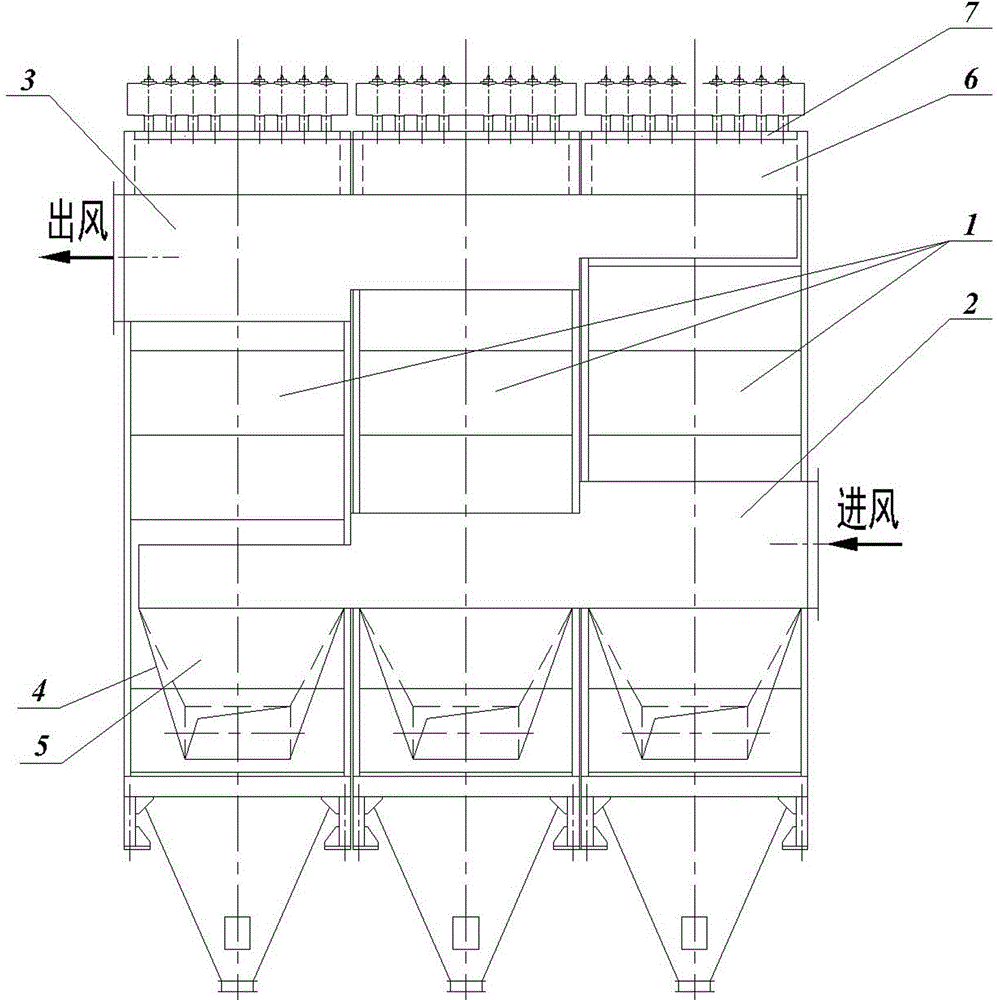

[0031] 1. See Figure 4 In the modular bag filter provided by the present invention, the standard module 1 of the bag filter has a complete bag filter structure and has the function and characteristics of independently completing flue gas purification.

[0032] The standard module 1 is mainly composed of an upper box body 8, a blowing device 9, a middle box body 10, a ash hopper 11, a column and frame 12, a baffle 13, a filter bag 14, a bag cage 15 and other components. The standard module 1 has a complete structure, and is completely processed in the factory and assembled into a single structure with independent working ability.

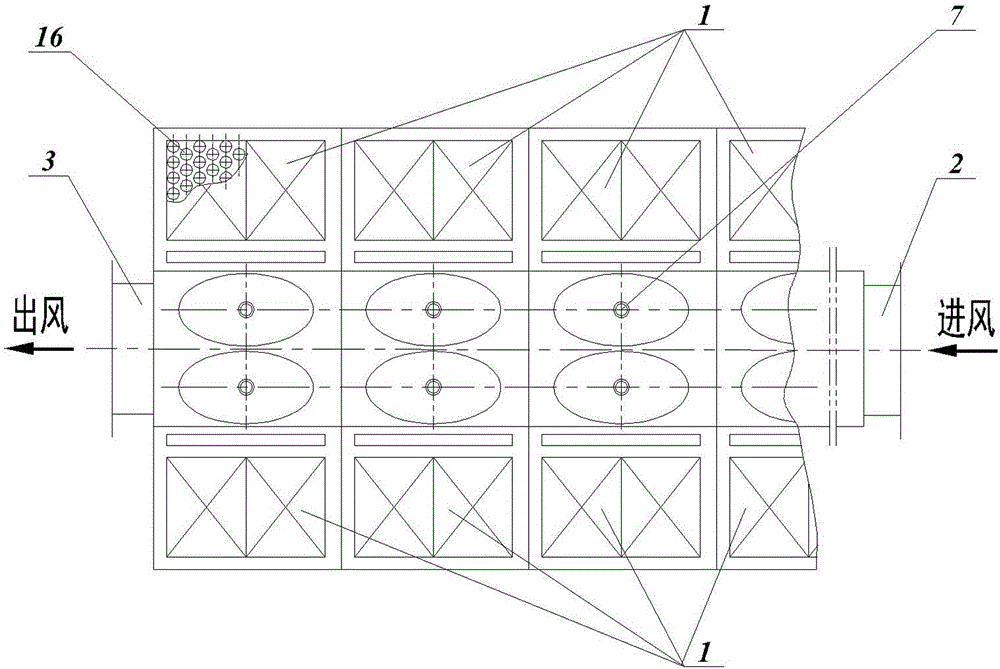

[0033] 2. See image 3 , Is a modular modular bag filter in the form of a single-row standard modular assembly of the present invention. Two adjacent standard modules 1 adopt conventional mechanical connections to form a single-row standard modular assembly. On one side of the single-row standard modular assembly Connected in sequence are: inlet main pip...

Embodiment 2

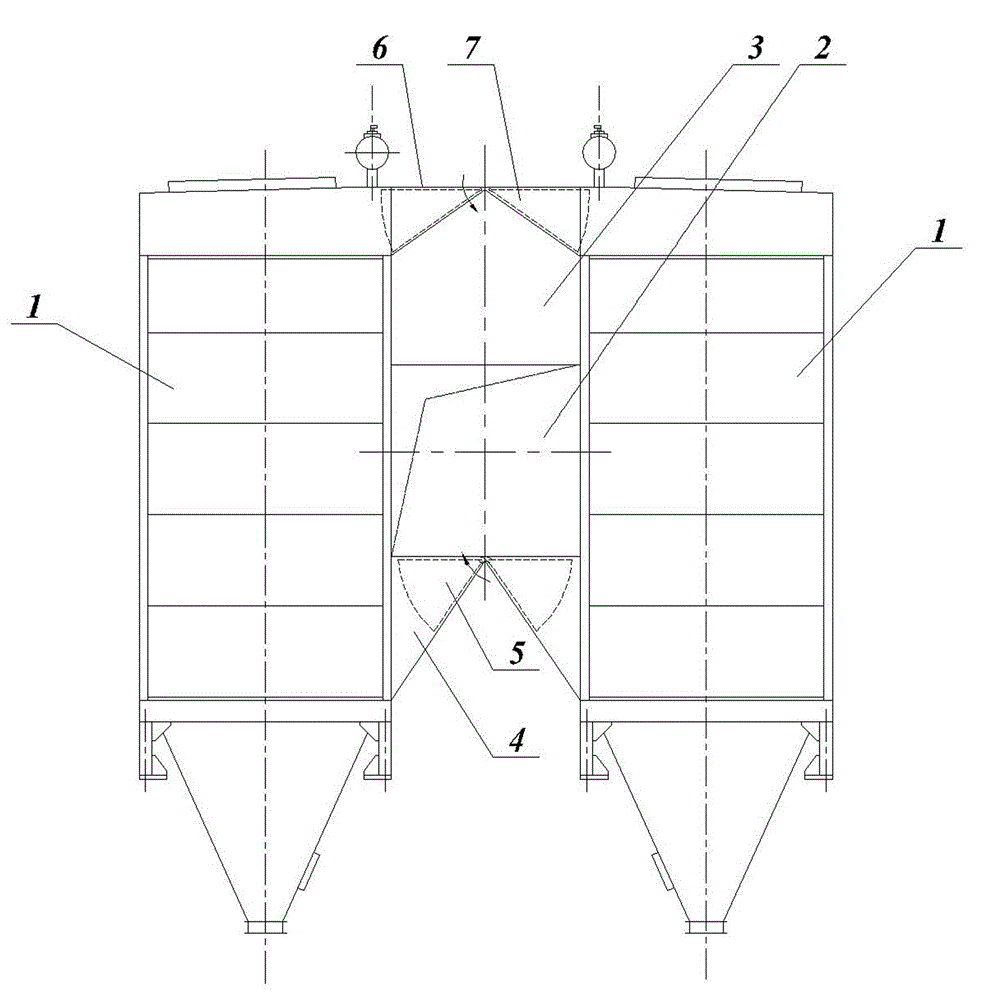

[0035] See figure 1 , figure 2 , Is the double-row standard module combination bag filter provided by the present invention, which is mainly used to deal with large flue gas volume. In each single-row standard module combination, two adjacent standard modules 1 adopt conventional mechanical connection to form a single Row standard module combination; the two single row standard module combinations are connected in sequence: inlet main pipe 2, outlet main pipe 3, inlet branch pipe 4, inlet valve 5, outlet branch pipe 6, outlet valve 7, etc. Components, these components are also modular components made in the factory, and only need to install and connect on site.

Embodiment 3

[0037] See Figure 5 , The method for shipping modular combined bag filter provided by the present invention is to load the standard module 1 into a container and fix it as a whole.

[0038] Before shipment, first install the bag cages 15 into the pattern holes 16 of the box on the standard module 1 in advance at the factory; then lay the standard module 1 with the bag cages 15 on its back, and use a forklift or crane with a special pallet to load It is loaded into a standard container 22.

[0039] In order to prevent the standard module 1 from being damaged due to movement, displacement and collision in the container during transportation, a positioning stopper 17 must be set in the gap between its surroundings and the container 22, and the standard module 1 can be transported after being properly packed and reliably positioned.

[0040] Such as Image 6 , Figure 7 , Figure 8 As shown, the bag cage 15 required by the standard module 1 itself is pre-installed in the box of the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com