Method for purifying pesticide residues and special purifier thereof

A technology for pesticide residues and purifiers, which is applied in chemical/physical processes, preparation of test samples, ion exchange regeneration, etc., can solve the problems of time-consuming, solvent-consuming, complicated methods, systematic errors, etc., and achieves convenient operation and detection results. Accurate and purifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, purifier

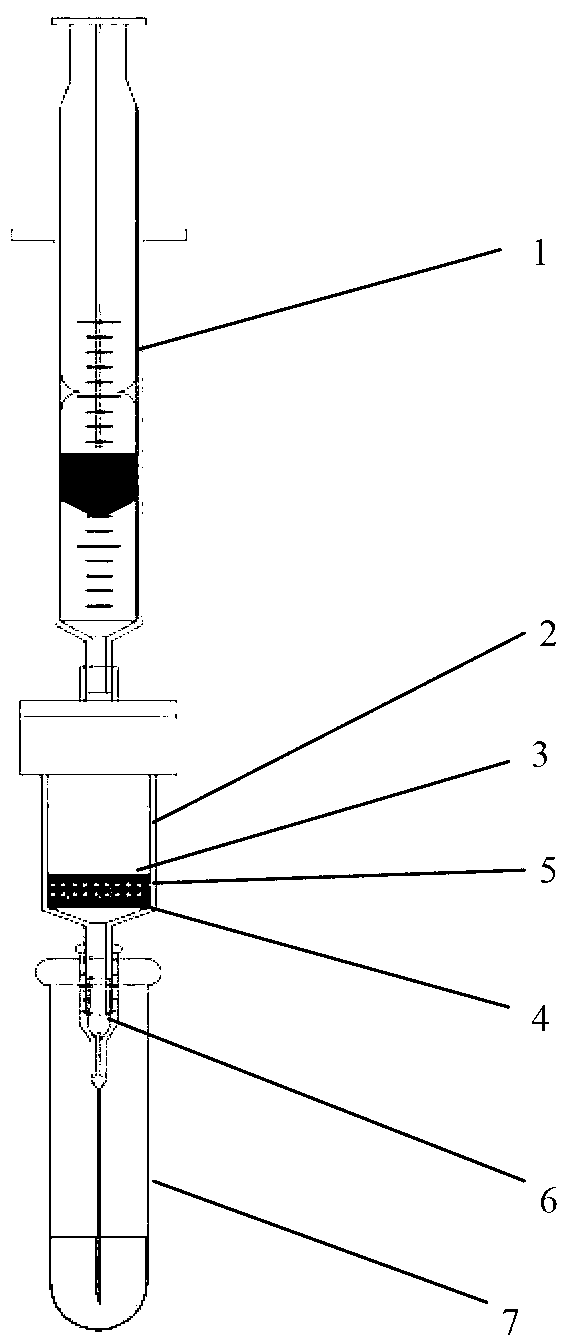

[0029] Such as figure 1 As shown, the purifier provided by the present invention includes a syringe 1 and a purification column 2; the purification column 2 is a cylindrical shape, and an upper sieve plate 3 distributed along its axial direction is provided near the end of the purification column 2 and the lower sieve plate 4, the upper sieve plate 3 and the lower sieve plate 4 are filled with adsorption filler 5, and both the upper sieve plate 3 and the lower sieve plate 4 have a mesh structure with a pore size of 20 μm, stable physical and chemical properties, and can It acts as a filter and barrier; one end of the purification column 2 away from the adsorption filler 5 is sealed with the syringe 1, and one end of the purification column 2 with the adsorption filler 5 is connected to the needle 6 for extracting the extract.

[0030] In the above-mentioned purifier, the pore size of the upper sieve plate and the lower sieve plate can be adjust...

Embodiment 2

[0031] Example 2. Analysis of pesticide residues in tomato (vegetable)

[0032] Utilize the clarifier that embodiment 1 provides to analyze.

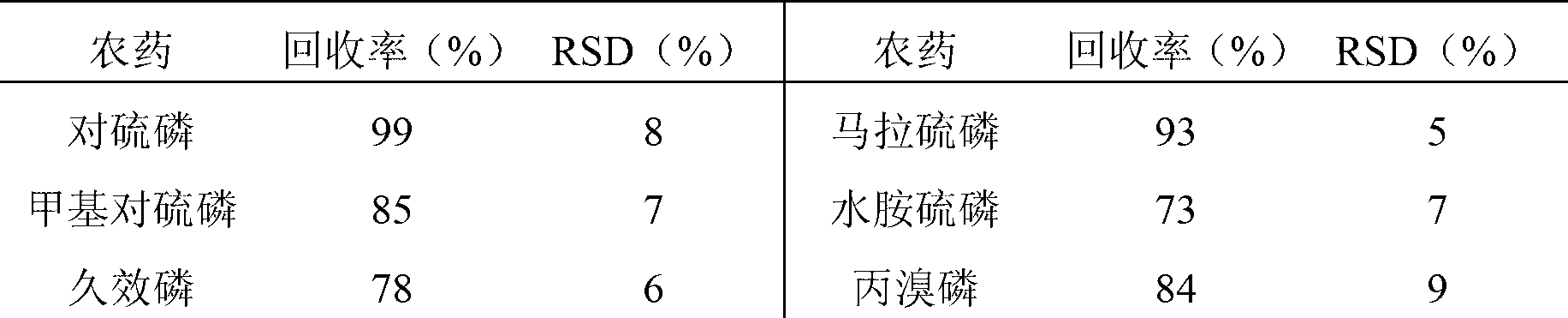

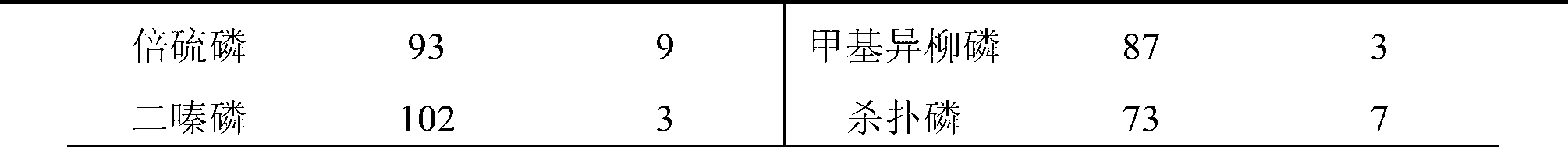

[0033] Types of pesticide residues: organophosphorus pesticides (parathion, methyl parathion, monocrotophos, malathion, isocarbophos, profenofos, methyl isofenphos, fenthion, diazines Phosphorus and Phosphorus);

[0034] Purification column packing preparation: 200 mg of adsorption packing, including 50 mg of N-propylethylenediamine, 150 mg of anhydrous magnesium sulfate, and a particle size of 40-100 μm;

[0035] Specific steps are as follows:

[0036] (1) Prepare the sample solution, use 10mL acetonitrile (containing 1% formic acid by volume) to extract the analyte in the tomato to obtain the extract solution, wherein the concentration of pesticide in the extract solution is 0.1mg / L;

[0037] (2) Pipette 1mL of the extract solution into the centrifuge tube 7, draw the extract solution into the purification column 2 with the syringe...

Embodiment 3

[0044] Example 3. Analysis of pesticide residues in grapes (fruits)

[0045] Utilize the clarifier that embodiment 1 provides to analyze.

[0046] Types of pesticide residues: organochlorine pesticides (pentachloronitrobenzene, α-666, β-666, γ-666, DDT and procymidone);

[0047] Purification column packing preparation: 160 mg of adsorption packing, including 10 mg of multi-walled carbon nanotubes (with a diameter of 10-20 nm), 150 mg of anhydrous magnesium sulfate, and a particle size of 5-100 μm;

[0048] Specific steps are as follows:

[0049] (1) Prepare the sample solution, use 10mL of acetonitrile to extract the analytes in the grapes to obtain the extract, and the residual concentration of pesticides in the extract is 0.1mg / L;

[0050] (2) Pipette 1mL of the extract into the centrifuge tube 7, draw the extract into the purification column 2 with the syringe 1, and then push out the solution into the centrifuge tube 7;

[0051] (3) The purified extract enters the sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com