Pre-pressure cooker

A technology for pressure cooker and pressure detection, which is applied in the direction of pressure cooker, etc., can solve the problem of low heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

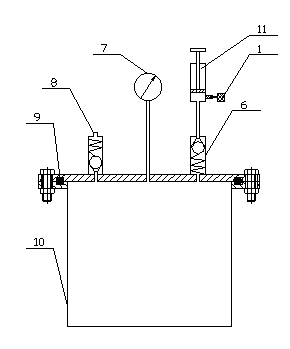

[0014] Such as figure 1 As shown, the pre-pressure cooker of the present invention includes a sealed heating cavity 10 composed of a box body and an end cover. The sealed heating cavity 10 can be a household pot, a microwave oven, an oven and other cooking utensils, and the sealed heating cavity The body 10 is provided with a safety valve 8 and a pressure sensor 7 for detecting pressure and outputting a pressure signal, and an air inlet check valve 6 is provided on the sealed heating cavity 10, and an air pump that can inflate the sealed heating cavity 10 passes through The air intake check valve 6 is connected with the sealed heating chamber 10, and the air pump mentioned in this embodiment is a manual air pump, and an air filter 1 can be arranged on the manual air pump simultaneously.

Embodiment 2

[0016] Such as figure 2 As shown, the pre-pressure cooker of the present invention includes a sealed heating cavity 10 composed of a box body and an end cover. The sealed heating cavity 10 can be a household pot, a microwave oven, an oven and other cooking utensils, and the sealed heating cavity The body 10 is provided with a safety valve 8 and a pressure sensor 7 for detecting pressure and outputting a pressure signal, and an air inlet check valve 6 is provided on the sealed heating cavity 10, and an air pump that can inflate the sealed heating cavity 10 passes through The air intake check valve 6 is connected with the sealed heating cavity 10, and the pressure sensor 7 is connected with a control circuit 5 that can receive the pressure signal output by the pressure sensor 7; the air pump mentioned in this embodiment is an electric air pump, and the electric air pump An air filter 1 is arranged on it, the control circuit 5 is connected to the air pump motor 2 of the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com