Sealing assembly for a rolling bearing

A technology for sealing devices and rolling bearings, which is applied to rolling contact bearings, engine seals, and rotating bearings, etc. It can solve problems such as elastic body wear and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

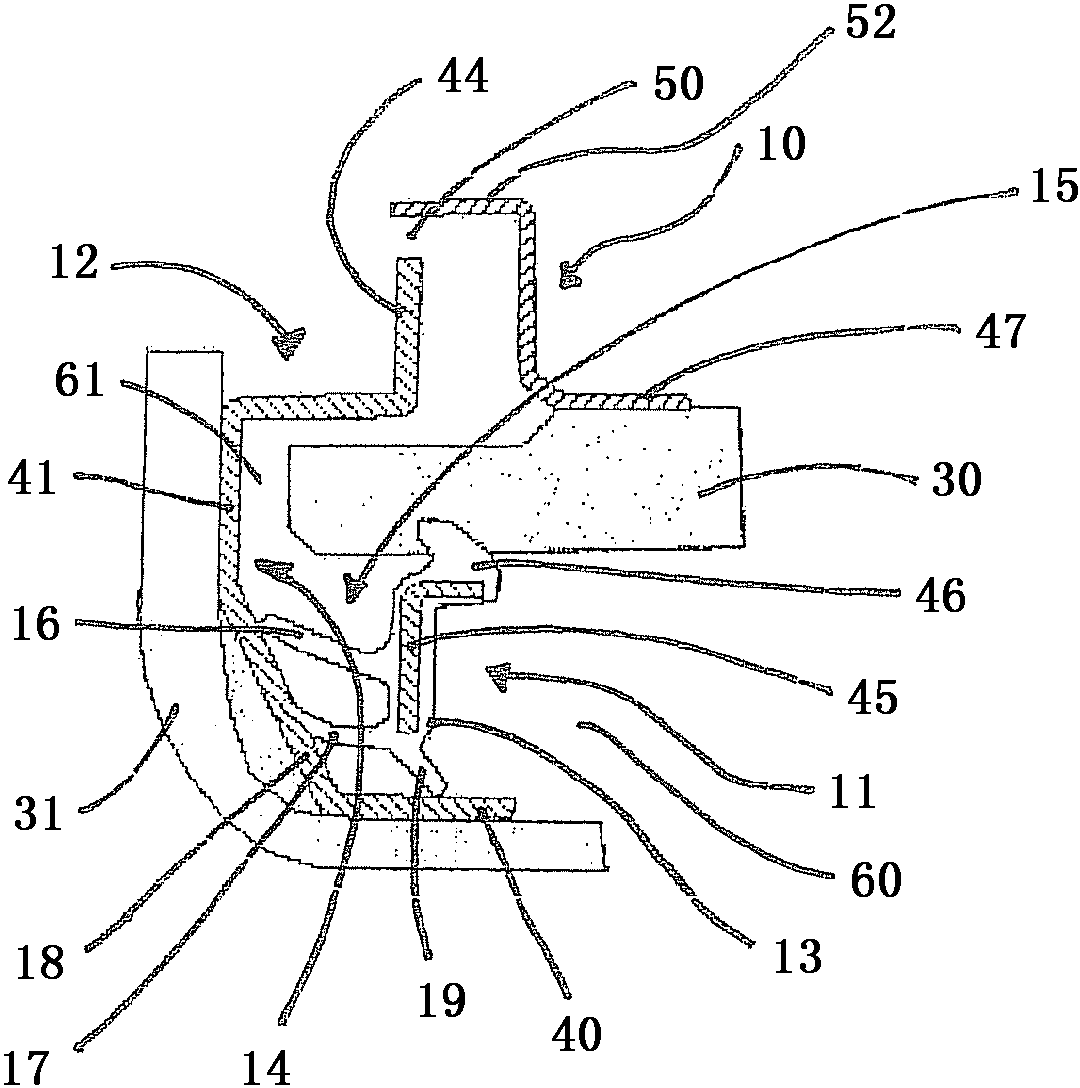

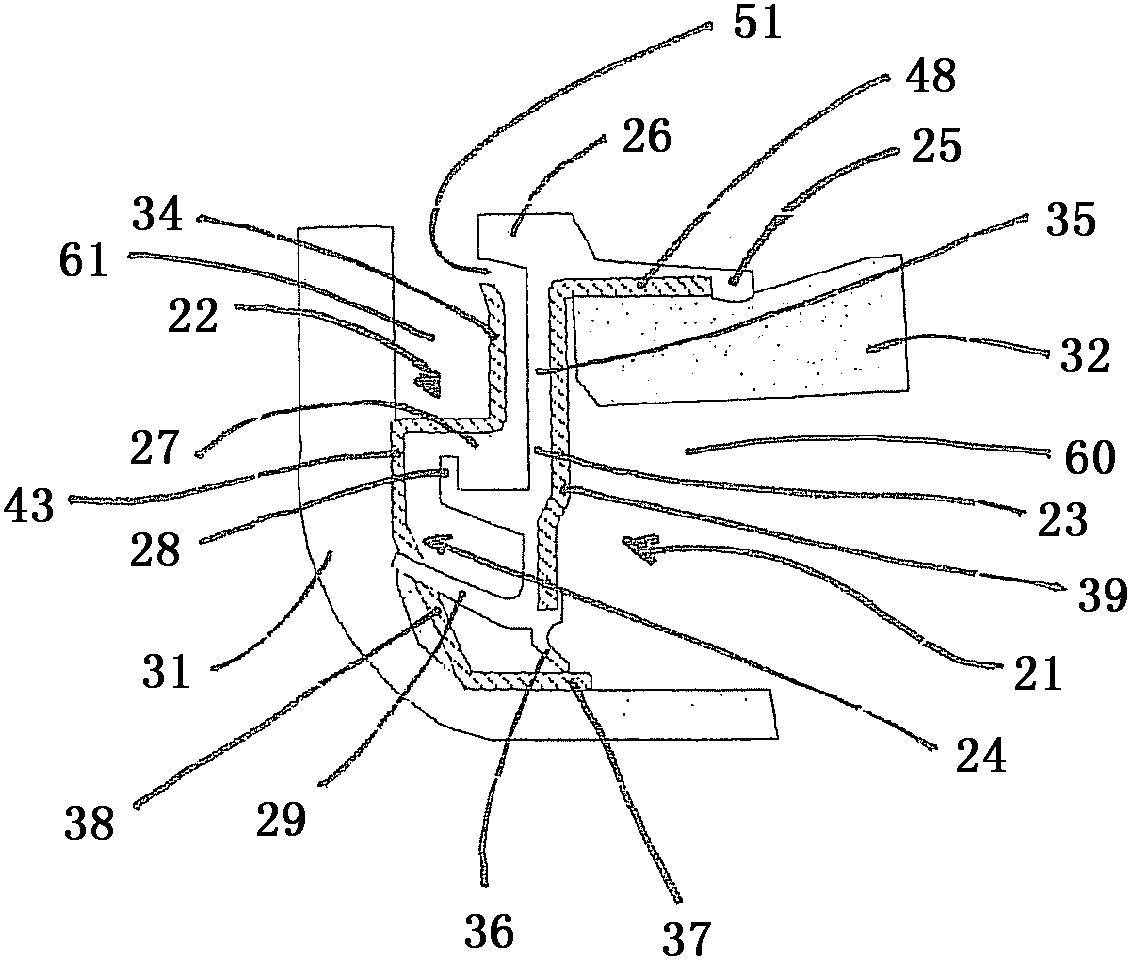

[0032] figure 1 A three-part seal with cover part 10 is shown. The sealing device has a frictionless pre-seal which is designed as a labyrinth seal and is formed by the contact part 14 , the first bearing part 30 and the cover part 10 . In this case, the cover part 10 is embodied as a cold-formed plate, wherein an annular opening 50 is arranged at the end of the hollow-cylindrical section 52 , which opens into the first collecting groove 12 of the contact part 14 . Alternatively, the cover part 10 can also consist of plastic or be machined as a turned part. Furthermore, the cover part 10 has a fastening part 47 which is fastened by means of a press fit to the outer surface of the first bearing part 30 embodied as an outer ring.

[0033] The outer ring forms, for example, at least part of the hub 30 , whereby the cover part 10 becomes a kind of centrifugal plate from which water escapes radially and away from the opening 50 during rotational operation. The water and dirt par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com