Edge shielding structure of electric reactor magnetic shielding plate

A shielding structure and magnetic shielding technology, applied in the fields of magnetic field/electric field shielding, preventing/reducing unwanted electrical/magnetic effects, electrical components, etc. Achieve the effect of improving electrode shape and reducing the risk of partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below through embodiments in conjunction with the accompanying drawings.

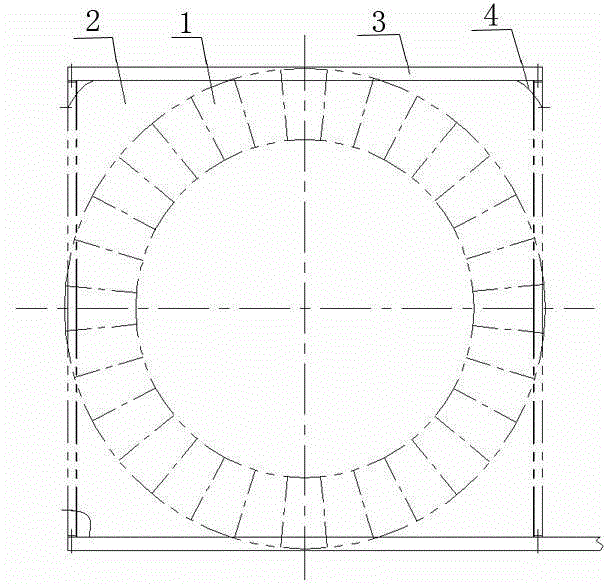

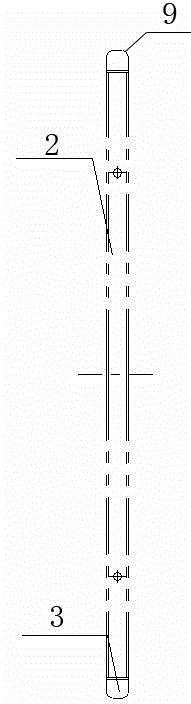

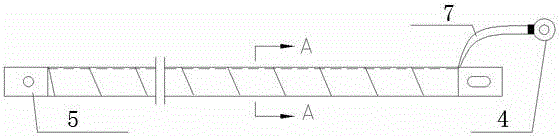

[0015] The edge corrugated shielding structure of the magnetic shielding plate of the reactor, including laminated wood wire clip 5, aluminum foil crepe paper 6, copper braided wire 7 and crepe paper 8, one side of the laminated wood wire clip is rounded 9, covered with aluminum foil crepe paper , place a copper braided wire inside the aluminum foil crepe paper, wrap the aluminum foil crepe paper with crepe paper, and crimp the exposed head of the copper braided wire with a crimping joint 4 to form an edge shield 3; the edge shield is installed with a glass fiber screw on the magnetic On the shielding plate 2, the rounded side of the laminated wood wire clip faces outward, and the crimping joint is fixed on the metal structure of the magnetic shielding plate by stainless steel fasteners, so as to improve the electric field environment at the sharp co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com