Water-cooled motor test platform and use method

A test platform and water-cooled motor technology, applied in the direction of motor generator testing, etc., can solve the problems of reducing the service life of the traction motor, affecting the efficiency of the motor, and affecting the accuracy of the power value, so as to achieve the effect of ensuring the working life and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiment of water-cooled motor test platform

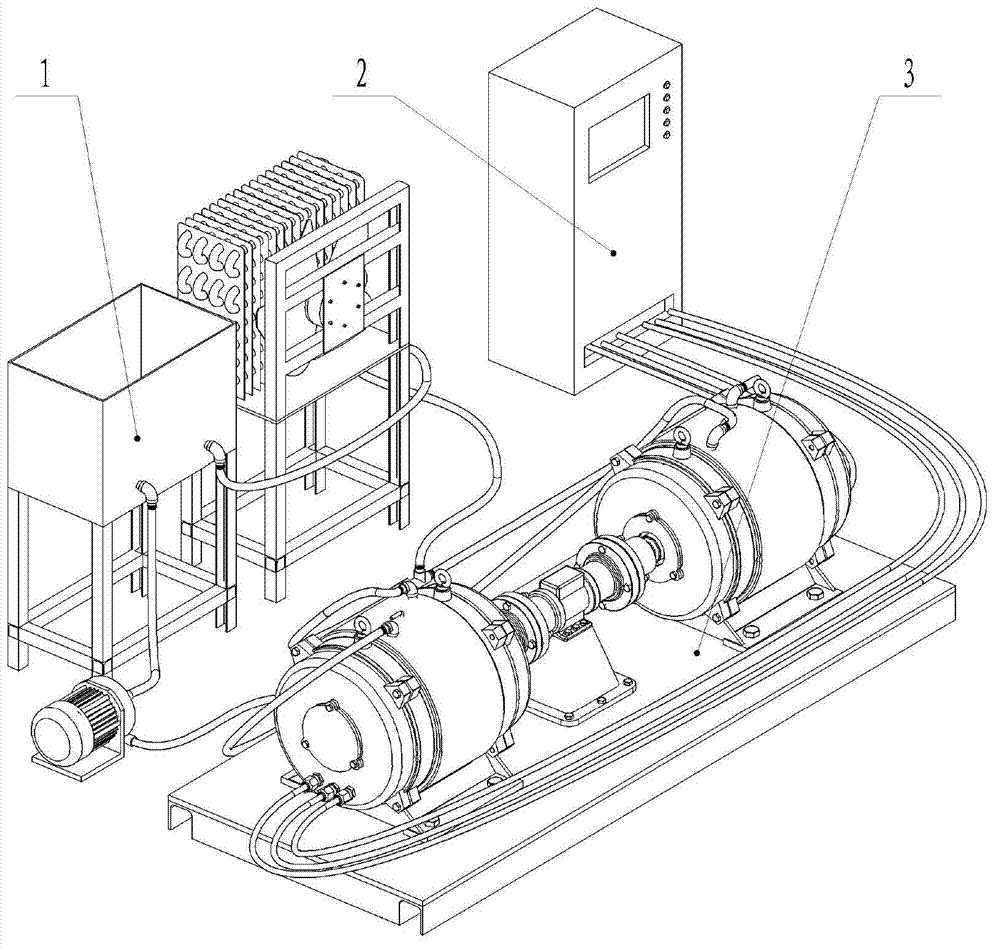

[0034] In this example, the water-cooled motor test platform is as follows: figure 1 As shown, it includes three parts: water cooling system 1, control system 2 and test bench 3.

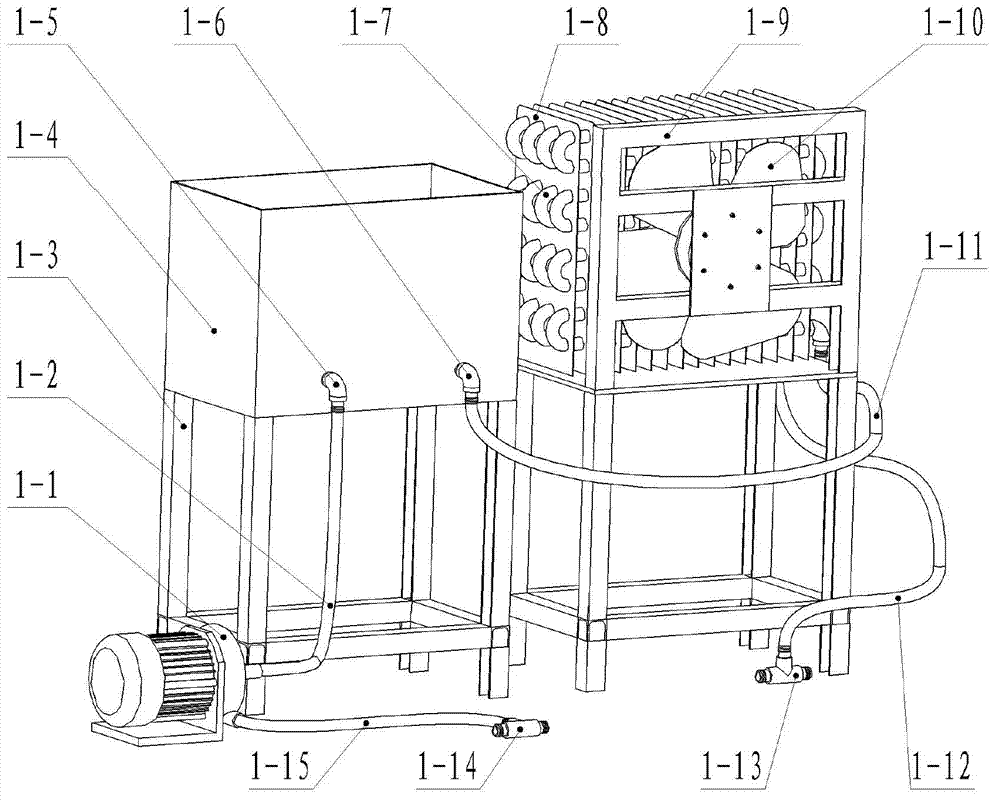

[0035] In this example, the water cooling system 1 such as figure 2 As shown, including a water tank 1-4, a circulating water pump 1-1 and a radiator, the motor 3-6 under test and the drag motor 3-2 are all equipped with a water-cooled casing. The volume of the water tank 1-4 of this example is 2 times of the volume of the water-cooled casing of the two motors, the volume of the cooling pipe 1-7, the volume of the circulating water pump 1-1 and the sum of the volume of each connected water pipe. The water tank 1-4 is installed on the water tank frame, the water outlet interface 1-5 of the water tank is higher than the water inlet of the water-cooled casing of the motor 3-6 under test and the towing motor 3-2, and the water outlet interface 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com