Heat collection plate of solar energy flat plate collector

A solar panel and heat collector technology, which is applied to solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of reduced heat collection efficiency, difficult leveling, and unfavorable heat exchange, so as to improve heat exchange efficiency and prolong service life. The effect of short life and heat transfer path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

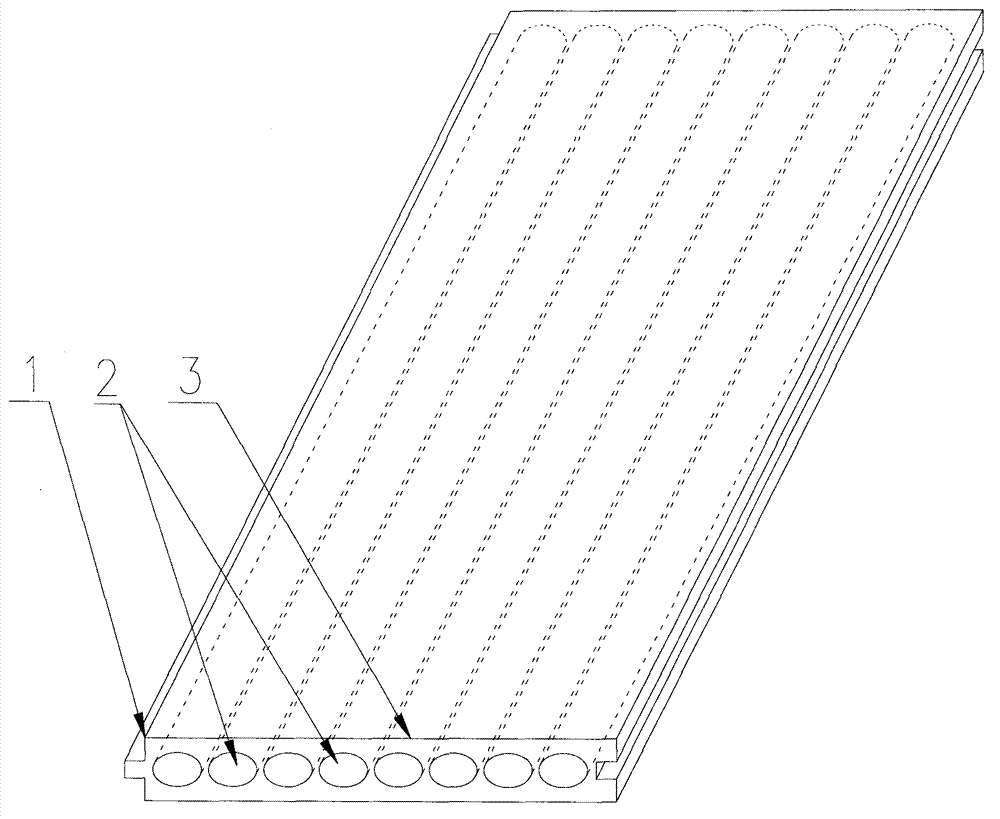

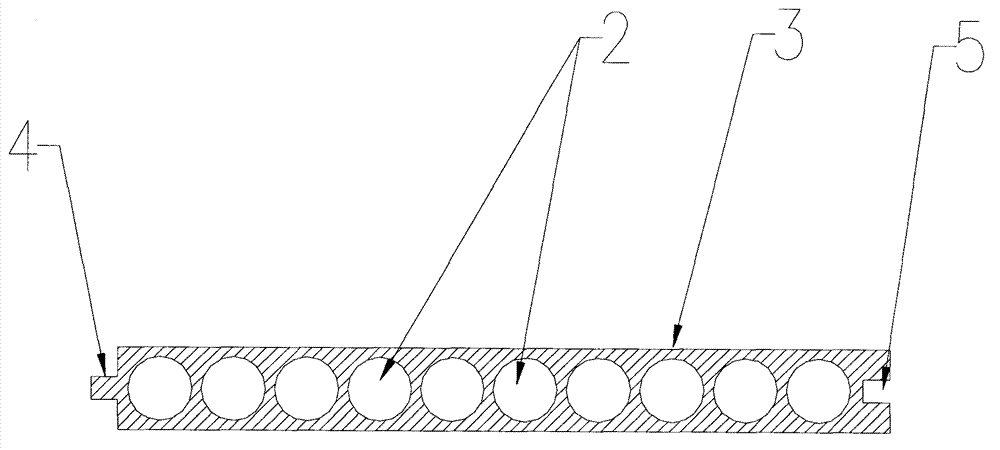

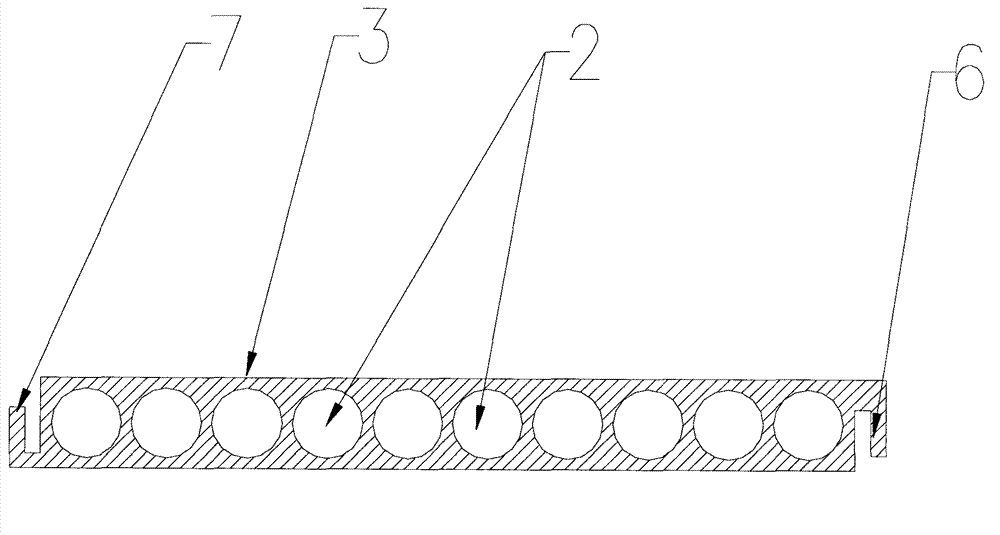

[0016] see figure 1 The heat collecting plate of the solar panel heat collector includes a heat collecting plate body 1, and at least two cavities parallel to each other are arranged in the heat collecting plate body 1; the cavity and the heat collecting plate body 1 are integrally formed , forming mutually parallel tubular flow channels 2; the upper surface 3 of the heat collecting plate body 1 is coated or plated with a selective absorption coating. The heat collecting plate body 1 is an extruded aluminum alloy heat collecting plate body, and the cross section of the tubular flow channel 2 is square, rectangular, circular or elliptical, which is circular in this embodiment. Both sides of the heat collecting plate body 1 are respectively provided with connecting interfaces for splicing two adjacent heat collecting plate bodies 1 into a whole, such as figure 2 As shown, the connecting interfaces on both sides of the heat collecting plate body are connecting protrusion 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com