Compressed-air storage device and natural energy power station with same

A gas storage device and compressed air technology, applied in fixed capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve problems such as inability to bear pressure, and achieve low cost, large volume, and high yield strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

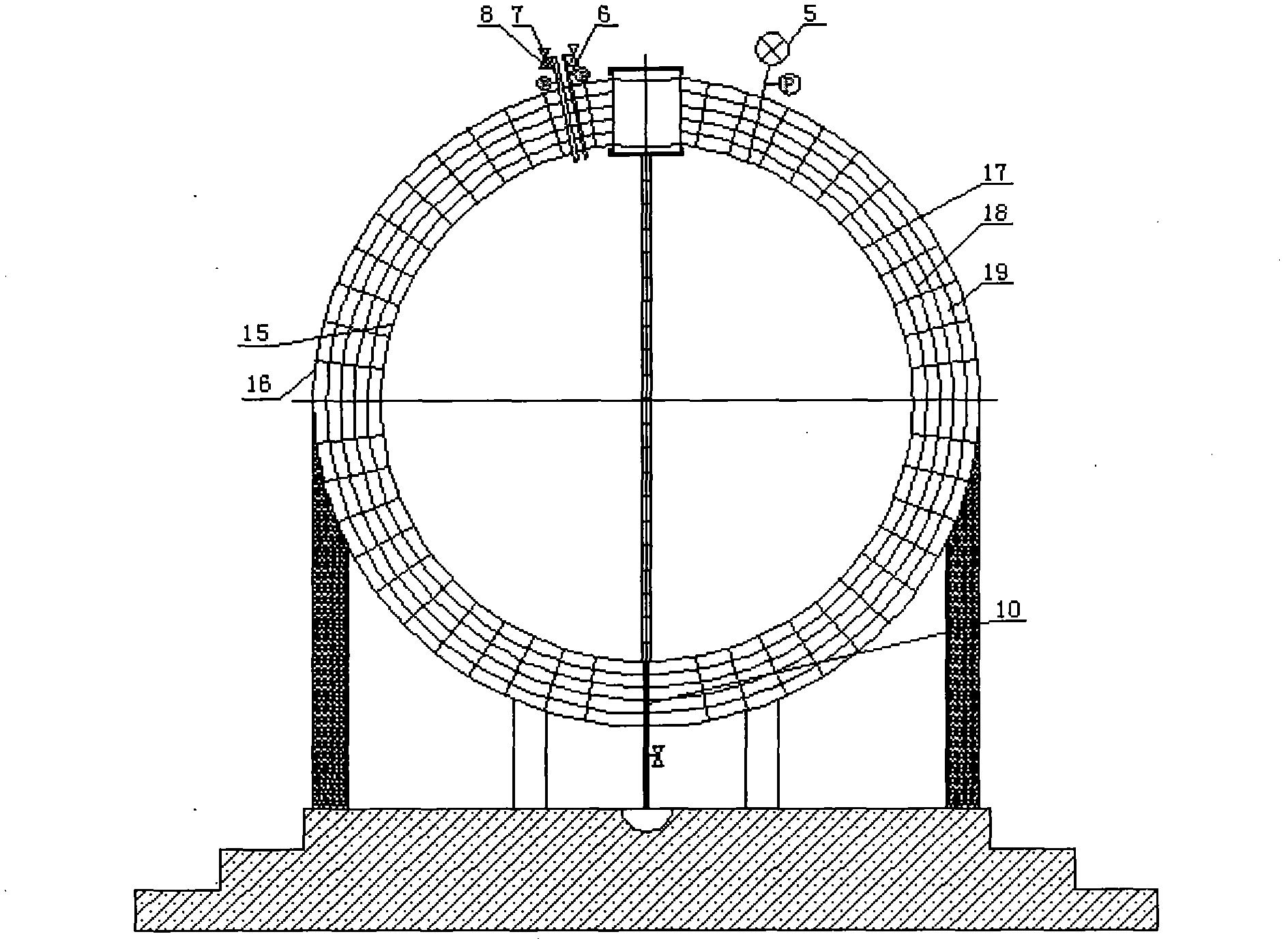

[0054] Such as figure 1 with figure 2 As shown, the decompression gas storage device of compressed air includes a spherical decompression gas storage tank 1, a sealing device and a drainage device. The decompression gas storage tank 1 is placed on six cement pillars 14, and the six cement pillars 14 are evenly distributed on the upper plane of the cement abutment 2, and the decompression gas storage tank 1 is lifted up so that the decompression gas storage tank 1 Smoother, eliminating vibration and noise.

[0055] The cement abutment 2 is a circular three-story staircase structure and is placed below the horizon. The upper plane of the cement abutment 2 is flush with the ground, and the radius of the upper plane is the smallest and larger than the radius of the pressure-reducing gas storage tank 1 . The installation method of placing the cement abutment 2 below the horizon can make the placement of the pressure-reducing air storage tank 1 more stable with less vibration. T...

Embodiment 2

[0064] The depressurization gas storage device for compressed air, the positional relationship and connection relationship between each component, and the natural energy power station equipped with this device are the same as the first embodiment.

[0065] Such as image 3 with Figure 4 As shown, the material of the shell inner wall 15 and the shell outer wall 16 of the step-down gas storage tank 1 is ship plate steel with a yield strength of 820MPa and a thickness of 7mm. Ship plate steel has high yield strength, high low temperature impact toughness, good welding performance and cold bending resistance. The volume of step-down gas storage tank 1 is 1022m 3 , capable of carrying a pressure of 1550 atmospheres.

Embodiment 3

[0067] The depressurization gas storage device for compressed air, the positional relationship and connection relationship between each component, and the natural energy power station equipped with this device are the same as the first and second embodiments.

[0068] Such as image 3 with Figure 4 As shown, the material of the shell inner wall 15 and the shell outer wall 16 of the decompression gas storage tank 1 is ship plate steel with a yield strength of 1000 MPa and a thickness of 10 mm. Ship plate steel has high yield strength, high low temperature impact toughness, good welding performance and cold bending resistance. The volume of step-down gas storage tank 1 is 1022m 3 , capable of carrying a pressure of 1800 atmospheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com