Zero-stiffness vibration isolator with rolling oscillating bearing angle degree decoupling function and vibration isolation system

A technology of joint bearing and vibration isolation system, which is applied in the directions of bearings, shafts and bearings, springs/shock absorbers, etc., can solve the problem of poor positioning accuracy of air spring vibration isolators, and does not solve the problem of accurate positioning of vibration isolators. Coupling, large angular stiffness of rubber blocks, etc., to solve the effect of low positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention are given below in conjunction with the accompanying drawings.

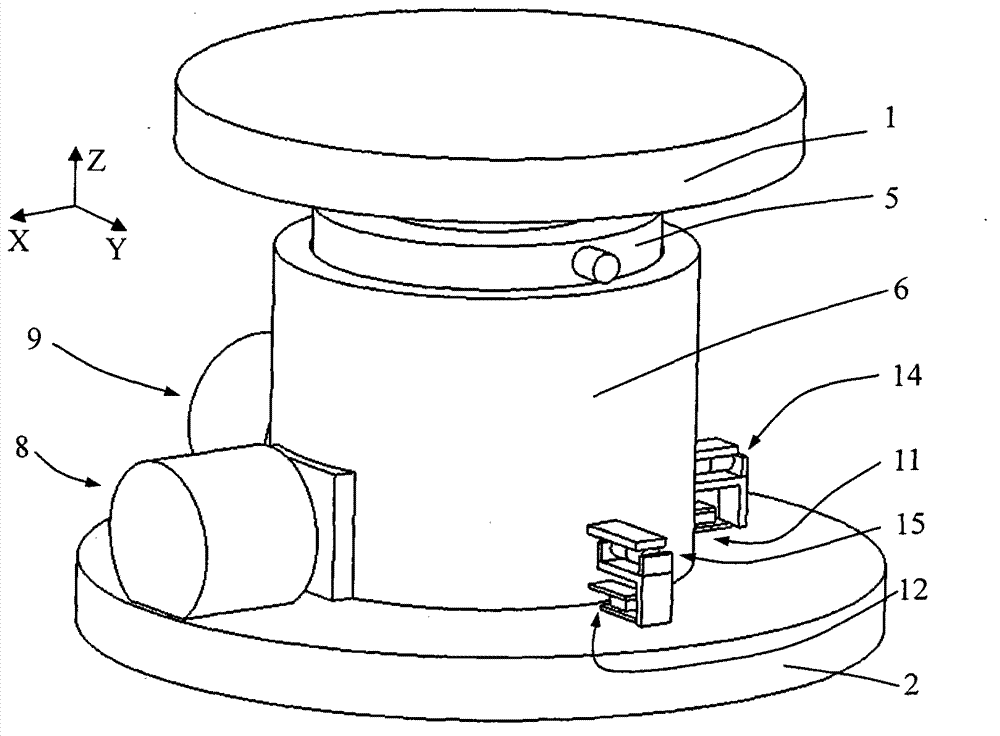

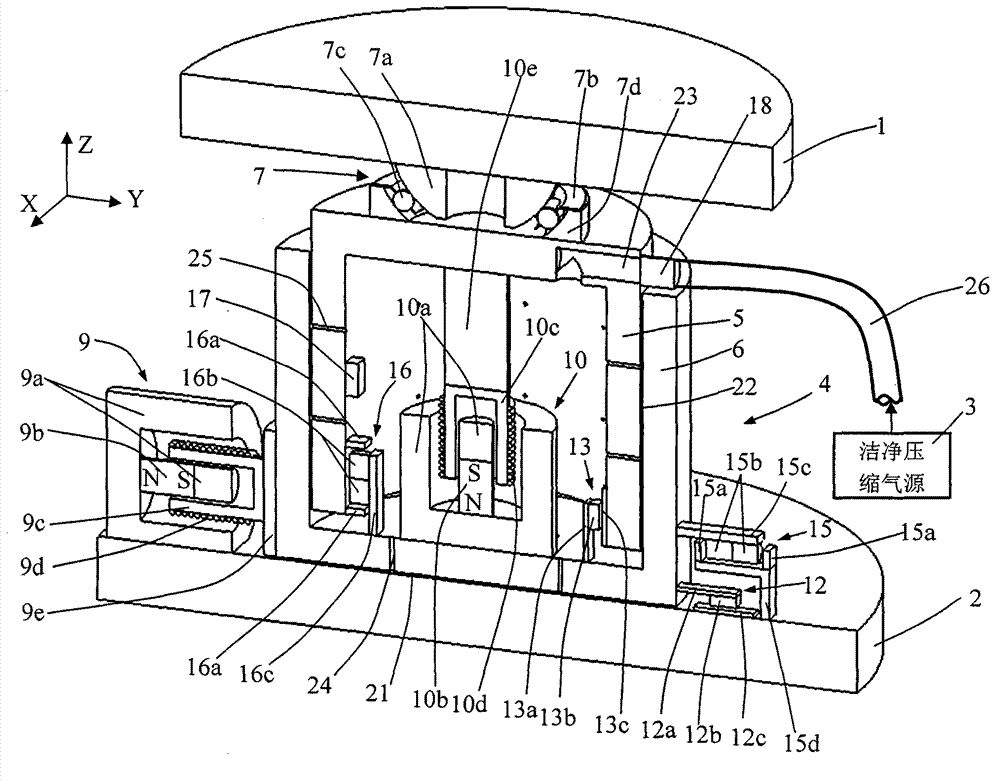

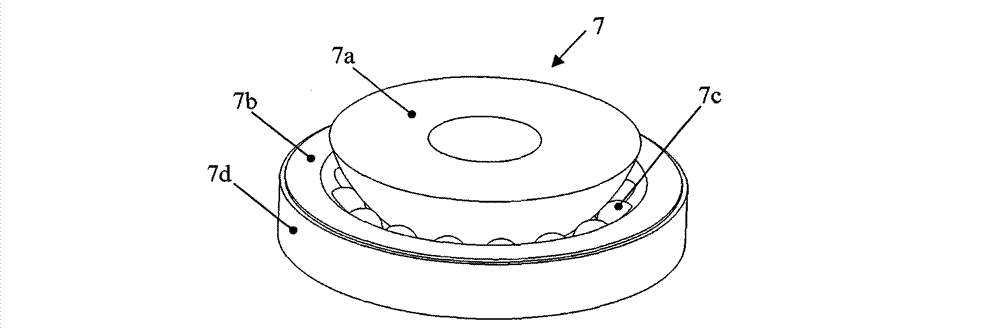

[0036] A zero-stiffness vibration isolator for angular decoupling of rolling joint bearings, consisting of an upper mounting plate 1, a lower mounting plate 2, a clean compressed air source 3, an air pipe 26 and a vibration isolator body 4, the vibration isolator body 4 is installed on the upper Between the mounting plate 1 and the lower mounting plate 2, the clean compressed air source 3 is connected to the vibration isolator main body 4 through the air pipe 26. In the structure of the vibration isolator main body 4, the lower surface of the sleeve 6 passes through the lower mounting plate 2. The axial bearing plane air bearing surface 21 is lubricated and supported, the piston barrel 5 is installed undercut in the sleeve 6, and is lubricated and supported with the sleeve 6 through the radial bearing cylindrical air bearing surface 22, and the rolling joint bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com