Fracturing bridge plug

A fracturing plug and fracturing ball technology, applied in the field of fracturing bridge plugs, can solve the problems of long milling time, difficult flowback, long sealing time, etc., and achieve the effect of saving milling time and improving milling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

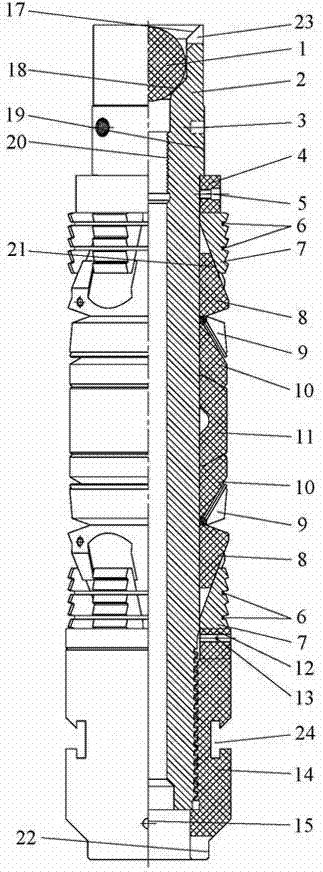

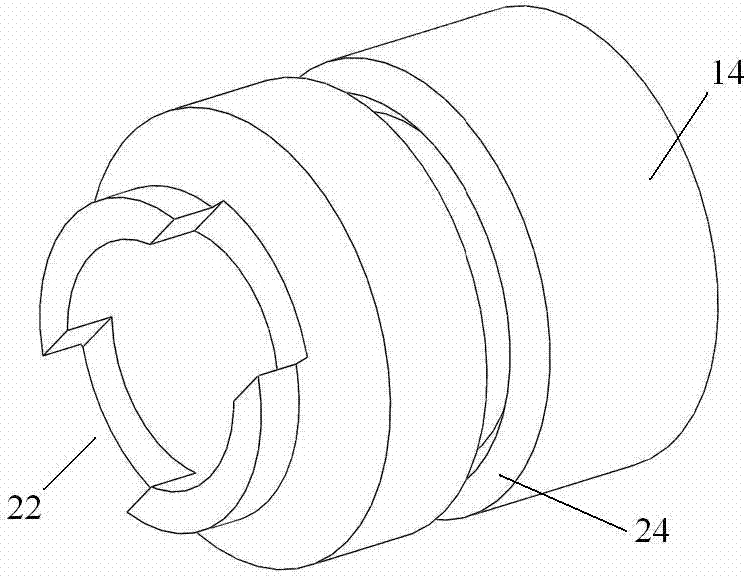

[0024] This embodiment provides a fracturing plug, such as figure 1 As shown, it includes fracturing ball 1, central tube 2, shear pin 3, upper slip 7, lower slip 7, slip ring 6, cone 8, end rubber cylinder 10, middle rubber cylinder 11 and guide shoe 14 , wherein, the outer diameter of the central tube 2 has a variable diameter step, the maximum outer diameter 19 places are provided with evenly distributed holes suitable for the shear pin 3, the central tube 2 is a radial hollow structure with an inner diameter; the upper end of the central tube 2 has a The fracturing ball cavity with the same inner diameter of the central tube 2, the fracturing ball 1 is placed in the fracturing ball cavity; the inner diameter of the central tube 2 and the fracturing ball cavity has an internal thread 20, which is convenient and fast for the fracturing bridge plug Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com