Buffing burnt-feeling water-based Yangbuck foaming resin and preparation method thereof

A foamed resin and water-sensitive technology, which is applied in the field of water-based yambar foamed resin and its preparation, can solve the problems of not being scratch resistant, not having a burnt feeling, and poor smoothing effect, etc., and achieve good scratch resistance, Imitation leather effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

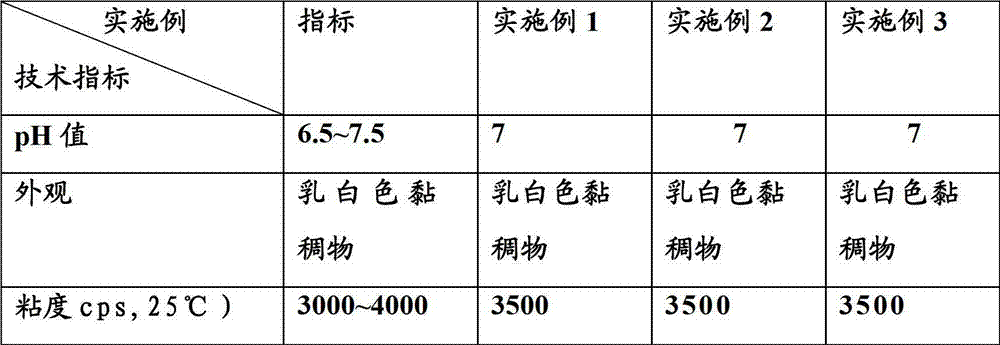

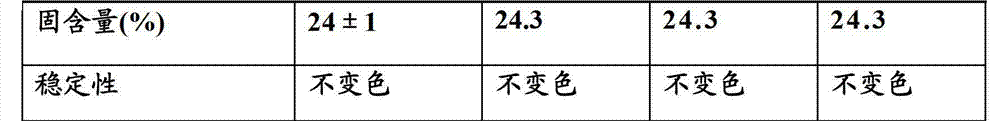

Embodiment 1

[0018] This example provides a water-based yangbuck foaming resin with a burnt skin texture. In parts by weight, its raw material formula is as follows: 50 parts of water-based acrylic resin; 45 parts of water; 1 part of modified silicone-based water-based defoamer; 3 parts of yangbuck powder; 6 parts of polyurethane water-based thickener; 3 parts of water-based scorching wax powder (polyethylene wax and amide wax mixture); 3 parts of water-based leveling agent (octylphenol polyoxyethylene ether); fungicide 0.8 parts of tetrachloroisophthalonitrile (TPN), 4 parts of organic bentonite.

[0019] The preparation method of the water-based yambuck foaming resin with scorching skin texture is as follows: disperse the organic bentonite with an equal amount of water; add the remaining amount of water, water-based leveling agent, yambuck powder, and water-based Rub scorched wax powder, stir until evenly dispersed, then add water-based defoamer, stir for a period of time (about 5 minute...

Embodiment 2

[0021] This example provides a kind of water-based yambuck foaming resin with a burnt skin texture, and its raw material formula is as follows in parts by weight: 50 parts of water-based acrylic resin; 45 parts of water; 1 part of water-based defoamer; 2 parts of fine yangbuck powder , 2 parts of coarse yangbuck powder; 6 parts of water-based thickener; 3 parts of water-based scorching wax powder; 3 parts of water-based leveling agent; 0.8 part of fungicide, 4 parts of organic bentonite. Among them: water-based defoamer is modified silicone defoamer, water-based thickener is polyurethane thickener, water-based scorching wax powder is a mixture of polyethylene wax and amide wax or purchased from Clariant, water-based leveling agent It is octylphenol polyoxyethylene ether, and the fungicide is tetrachloroisophthalonitrile (TPN). The preparation method of the scorched water-based yambuck foaming resin for dermabrasion is the same as that in Example 1.

Embodiment 3

[0023] This example provides a kind of water-based yambuck foaming resin with a burnt skin effect, and its raw material formula is as follows in parts by weight: 52 parts of water-based acrylic resin; 47 parts of water; 1.5 parts of water-based defoamer; 1 part of fine yambuck powder , 1 part of medium-sized yangbuck powder, 1 part of coarse yangbuck powder; 6 parts of water-based thickener; 3 parts of water-based scorching wax powder; 3 parts of water-based leveling agent; 0.5 part of fungicide, 5 parts of organic bentonite. Among them: water-based defoamer is modified silicone defoamer, water-based thickener is polyurethane thickener, water-based scorching wax powder is a mixture of polyethylene wax and amide wax or purchased from Clariant, water-based leveling agent It is octylphenol polyoxyethylene ether, and the fungicide is tetrachloroisophthalonitrile (TPN). The preparation method of the scorched-sensitivity water-based yangbuck foaming resin is the same as in Example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com