Magnetic roller

A technology of rollers and magnetic force, applied in textiles and papermaking, drafting equipment, spinning machines, etc., can solve the problems of affecting processing efficiency, straining fibers, and poor processing effects, so as to improve stability, avoid wear, and prevent forced The effect of turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] refer to figure 1 , image 3 , the magnetic roller includes a roller 100, the two ends of the roller 100 are pivotally connected to the roller support, and the two ends of the roller 100 and the roller support corresponding to the two ends are provided with a magnetic clutch device.

[0025] refer to figure 1 , figure 2 with image 3 The magnetic clutch device is composed of a roller end face provided with a first permanent magnet 110 and a driving cake 200 with a second permanent magnet 210 coaxially arranged opposite to the roller end face, the first permanent magnet 110 and the The magnetic pole connection line of the second permanent magnet 210 is arranged parallel to the axis of the roller 100 , and the polarity direction of the first permanent magnet 110 is opposite to that of the second permanent magnet 210 .

[0026] For the magnetic roller mentioned above, the first permanent magnets 110 and the second permanent magnets 210 are evenly distributed on the en...

Embodiment 2

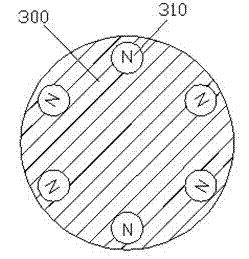

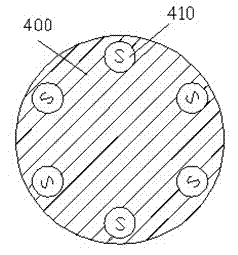

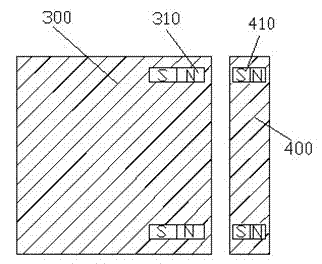

[0031] refer to Figure 4 , Image 6 , the magnetic roller includes a roller 300, the two ends of the roller 300 are pivotally connected to the roller support, and the two ends of the roller 300 and the roller support corresponding to the two ends are provided with a magnetic clutch device.

[0032] refer to Figure 4 , Figure 5 with Image 6 The magnetic clutch device is composed of a roller end face provided with a third permanent magnet 310 and a driving cake 400 with a fourth permanent magnet 410 coaxially arranged opposite to the roller end face, the third permanent magnet 310 and the The line connecting the magnetic poles of the fourth permanent magnet 410 is arranged perpendicular to the axis of the roller 300 , and the magnetic poles of the third permanent magnet 310 and the corresponding position of the fourth permanent magnet 410 are opposite.

[0033] For the magnetic roller mentioned above, the third permanent magnet 310 and the fourth permanent magnet 410 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com