A kind of thermoplastic starch plastic with high hydrophobicity and preparation method thereof

A thermoplastic starch and plastic technology, applied in the field of biodegradable plastics, can solve the problems of reducing the use of starch plastics, high cost of esterification reactants, poor fluidity, etc., to achieve full utilization of renewable resources, reduce pollution and dependence on petroleum products , the effect of good hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

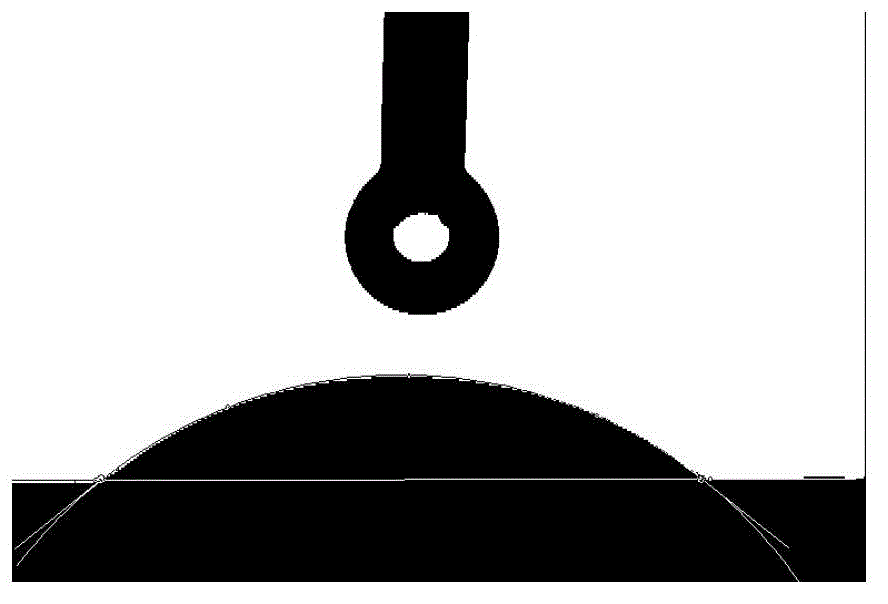

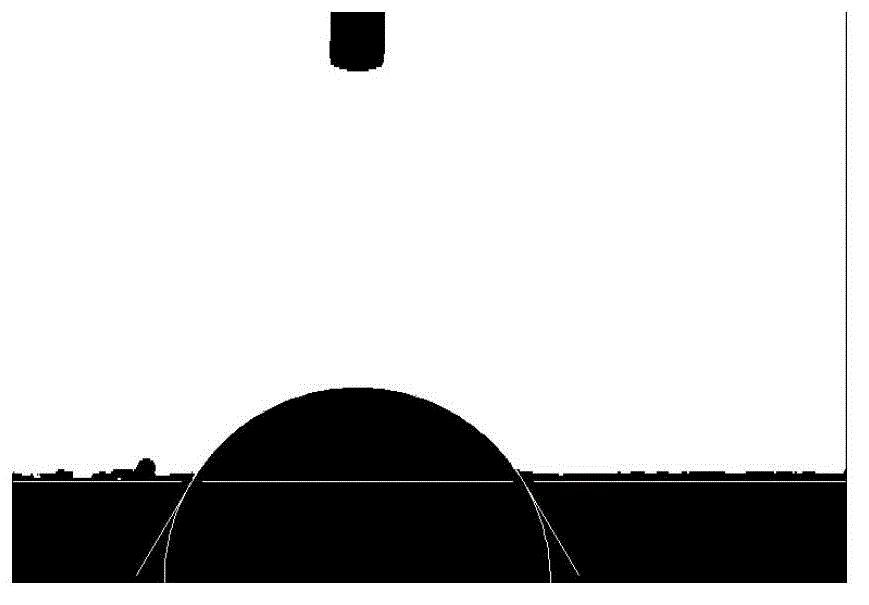

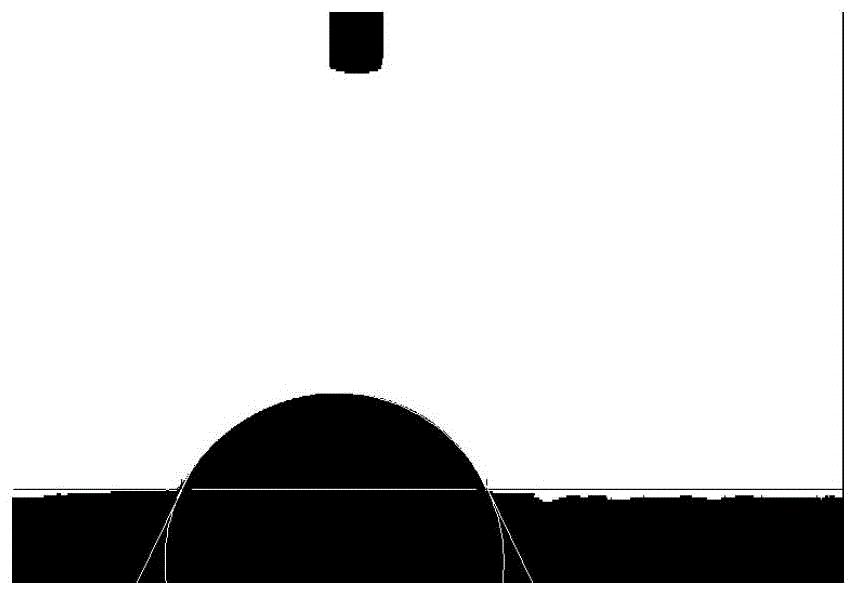

Image

Examples

Embodiment 1

[0072] The oxidized starch was prepared according to the method disclosed in the invention patent application with application number 200710050652.6, and its carbonyl content was 35%. Get 100 parts of oxidized starches with a carbonyl content of 35%, disperse them in 233 parts of water, and after high-speed stirring forms an emulsion with a concentration of 30%, add 15 parts of nitrile rubber emulsions, after high-speed stirring for 1 hour, adopt high-speed centrifugation, and use water ( It can be washed with industrial water) for 3 times, and dried in a vacuum oven for 24 hours to obtain the oxidized starch / elastic particle composite material sample; after high-speed crushing, the oxidized starch / elastic particle composite material with a mesh number of not less than 50 mesh can be obtained. Get 75 parts of oxidized starch / elastic particle composite material after pulverizing, after mixing evenly with 20 parts of glycerin, 2 parts of zinc stearate, 3 parts of liquid paraffin,...

Embodiment 2

[0074] According to the method disclosed in the invention patent application with application number 200710050652.6, the oxidized starch is prepared, and its carbonyl content is 35%. Take 100 parts of oxidized starch with a carbonyl content of 35%, disperse it in 233 parts of water, and stir it at a high speed to form a concentration of 30%. After the emulsion, add 20 parts of PU emulsion, stir at high speed for 1 hour, use high-speed centrifugation, wash with water (industrial water can be used) for 3 times, and dry in a vacuum oven for 24 hours to obtain the oxidized starch / elastic particle composite material sample . After high-speed crushing, the oxidized starch / elastic particle composite material with a mesh number not less than 50 mesh is obtained. Get 80 parts of oxidized starch / elastic particle composite material after pulverizing, mix with 15 parts of glycerol, 1 part of zinc stearate, 4 parts of liquid paraffin after mixing evenly, adopt twin-screw extruding, the asp...

Embodiment 3

[0076] According to the method disclosed in the invention patent application with the application number 200710050652.6, the oxidized starch is prepared, and its carbonyl content is 35%. Take 100 parts of oxidized starch with a carbonyl content of 35%, disperse it in 233 parts of water, and stir it at a high speed to form a 30% concentration. After the emulsion, add 5 parts of nitrile rubber emulsion, stir at high speed for 1 hour, use high-speed centrifugation, wash with water (industrial water can be used) for 3 times, and dry in a vacuum oven for 24 hours to obtain the composite of oxidized starch / elastic particle Material samples. After high-speed crushing, the oxidized starch / elastic particle composite material with a mesh number not less than 50 mesh is obtained. Get 80 parts of oxidized starch / elastic particle composite material after pulverizing, after mixing with 15 parts of formamide, 0.5 part of zinc stearate, 2 parts of liquid paraffin, and 2.5 parts of castor oil,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com