Novel fluorescent glass and preparation method thereof

A fluorescent glass and glass technology, applied in the field of new fluorescent glass and its preparation, can solve the problems of low luminous efficiency, inability to meet the requirements of high reliability, ultra-long life and high light transmittance, unstable luminous performance, etc. Luminous efficiency, improve light conversion efficiency, solve the effect of uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

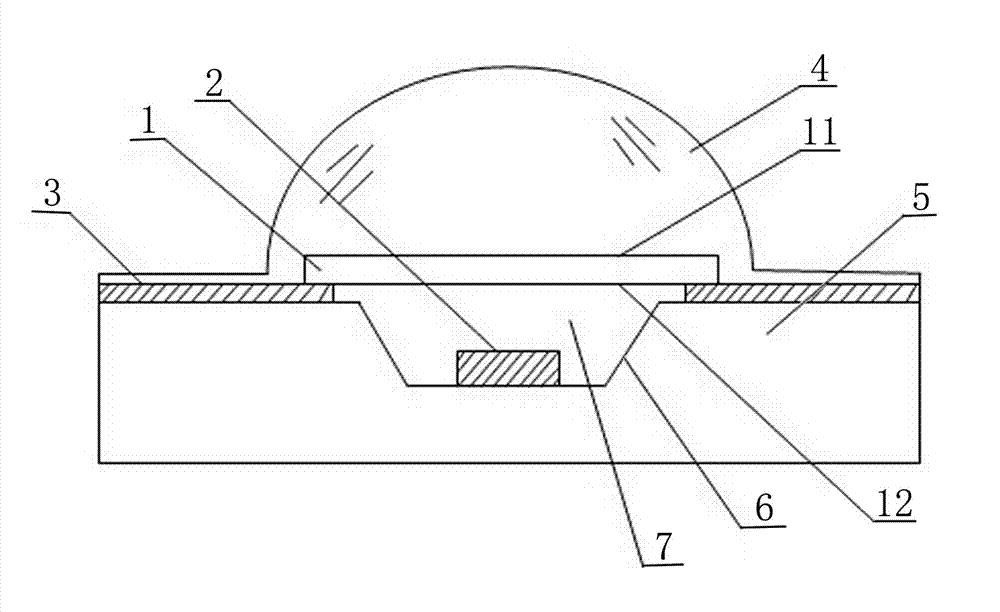

[0026] Novel fluorescent glass of the present invention, this fluorescent glass is made of P 2 o 5 , ZnO, MgO, Na 2 O. Li 2 The glass matrix composed of O and the Ce-YAG phosphor raw material are synthesized, wherein the molar percentage of each component of the glass matrix is: P 2 o 5 : 30%~50%, ZnO: 15%~30%, MgO: 15%~25%, Na 2 O: 5% to 13%, Li 2 O: 0.5% to 2%, and the amount of Ce-YAG phosphor accounts for 1% to 50% of the total weight of the glass matrix. Wherein, when each component in the present invention adopts the following percentage ranges, the effect is the best. At this time, the above-mentioned P 2 o 5 The molar percentage of ZnO in the glass matrix is 35% to 45%, the molar percentage of the above ZnO in the glass matrix is 18% to 25%, the molar percentage of the above MgO in the glass matrix is 18% to 20%, and the above Na 2 The molar percentage of O in the glass matrix is 6.5% to 10.5%, and the above Li 2 The molar percentage of O in the glass ...

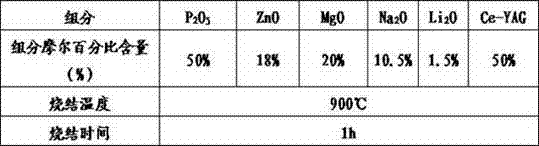

Embodiment 1

[0032] Embodiment 1: a kind of novel fluorescent glass, by P 2 o 5 , ZnO, MgO, Na 2 O. Li2 Synthesis of O and Ce-YAG phosphor raw materials. Raw material mole percentages and process parameters are shown in the table below:

[0033] 1)

[0034] 2) Weigh a certain weight of analytically pure raw material P according to the formula in the above table 2 o 5 , ZnO, MgO, sodium hexametaphosphate, Li 2 O and Ce-YAG phosphors.

[0035] 3) Calcining the glass matrix raw material at 1050°C and keeping it warm for 0.5-2h to obtain molten glass.

[0036] 4) Pour the obtained molten glass into cold water for water quenching to obtain a transparent glass matrix.

[0037] 5) Crush and ball mill the glass matrix obtained in the previous step to obtain micron-sized glass powder.

[0038] 6) Fully mix the glass powder with Ce-YAG fluorescent powder accounting for 10% by weight of the glass powder in a ball mill, calcining at 600°C for...

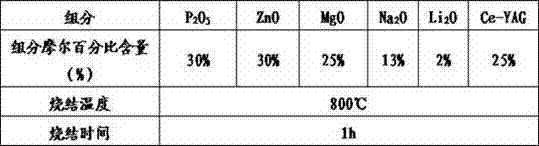

Embodiment 2

[0039] Embodiment 2: a kind of novel fluorescent glass, by P 2 o 5 , ZnO, MgO, Na 2 O. Li 2 Synthesis of O and Ce-YAG phosphor raw materials. Raw material mole percentages and process parameters are shown in the table below:

[0040] 7)

[0041] 8) Weigh a certain weight of analytically pure raw material P according to the formula in the above table 2 o 5 , ZnO, MgO, sodium hexametaphosphate, Li 2 O and Ce-YAG phosphors.

[0042] 9) Calcining the glass matrix raw material at 1050°C and keeping it warm for 0.5-2h to obtain molten glass.

[0043] 10) Pour the obtained molten glass into cold water for water quenching to obtain a transparent glass matrix.

[0044] 11) Crush and ball mill the glass matrix obtained in the previous step to obtain micron-sized glass powder.

[0045] 10) Fully mix the glass powder with Ce-YAG phosphor powder accounting for 15% by weight of the glass powder in a ball mill, calcining at 700°C for 1.5 hours, then casting, annealing, cutting, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com