Metal burner for preparing methanol synthesis gas

A technology for synthesis gas and methanol production, applied in the direction of non-metal elements, inorganic chemistry, chemical instruments and methods, etc., can solve problems such as damage to the economic benefits of enterprises, hidden dangers of enterprise safety production, and burnout, and achieve the goal of avoiding unplanned parking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

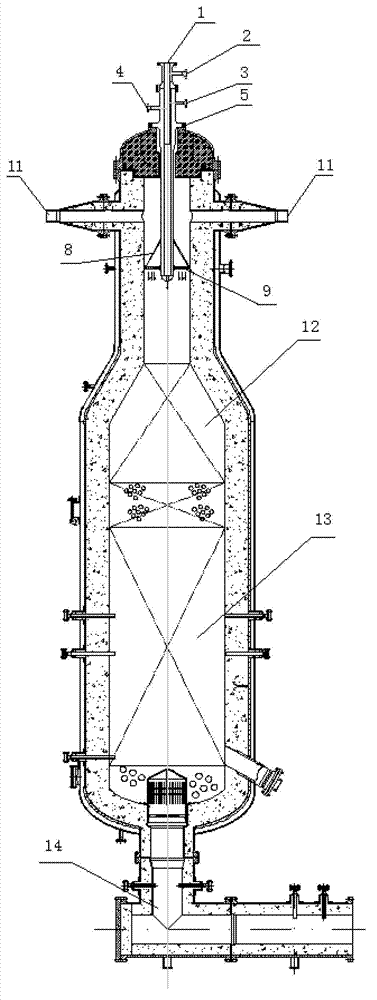

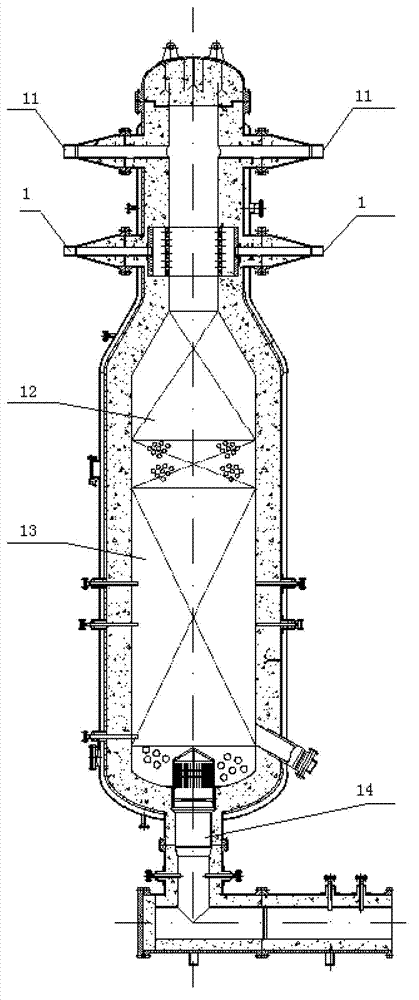

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

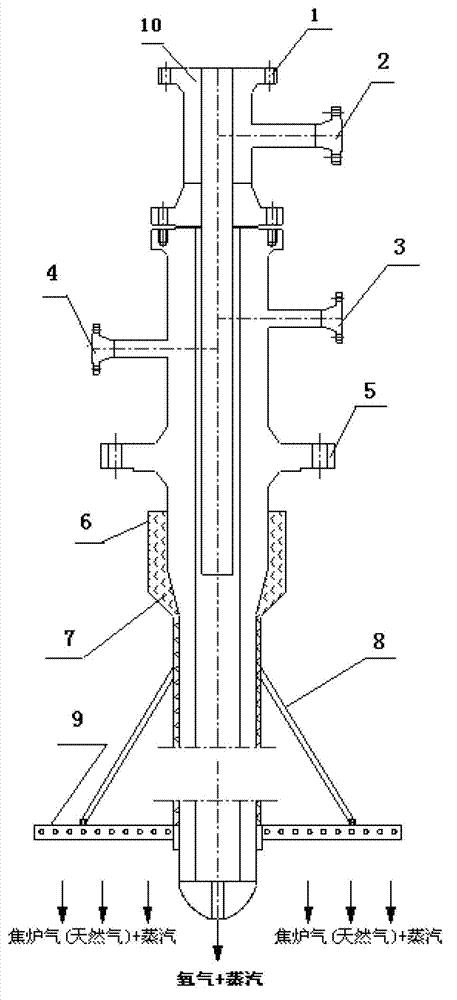

[0016] Such as figure 1 As shown, the metal burner of the present invention includes: oxygen / steam inlet flange 1, protection steam inlet flange 2, cooling water inlet flange 3, cooling water outlet flange 4, burner and furnace connecting flange 5, protection Sleeve 6, insulation cotton 7, cable-stayed ribs 8, gas distributor 9, burner body 10, coke oven gas / natural gas inlet 11.

[0017] The side wall of the burner body 10 is provided with a cooling water inlet and a cooling water outlet leading into the interior of the burner body, and a protective steam inlet leading into the interior of the burner body is also provided on the side wall of the burner body 10. The inlet end of the body 10 is provided with an oxygen / steam inlet, a protective sleeve 6 is provided at the part of the burner body 10 extending into the furnace, and a gas distributor 9 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com