Battery flexible packaging materials

A packaging material and flexible technology, applied in the field of flexible packaging materials, can solve the problems of reduced productivity, poor production timeliness, and various manufacturing processes, and achieve the effect of low thermal expansion coefficient and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

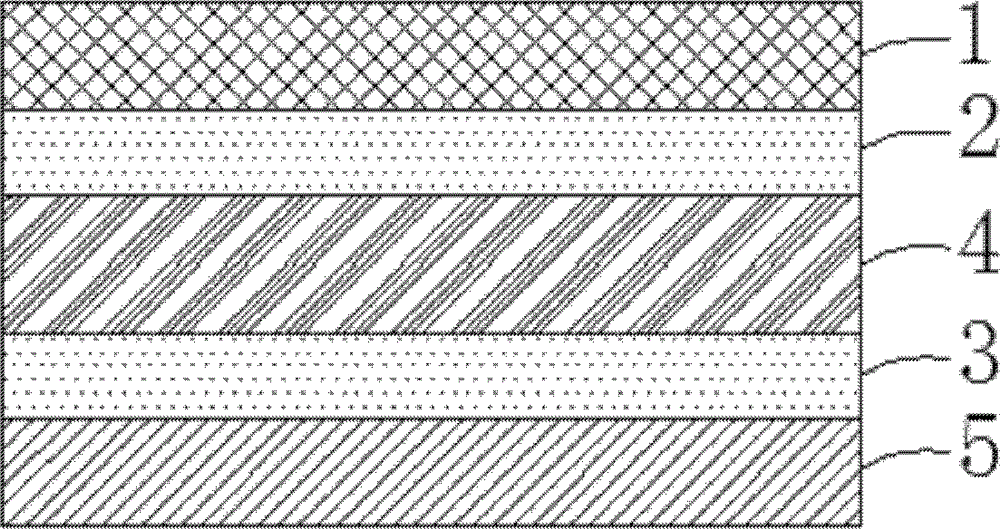

[0032] Example 1: A battery flexible packaging material, consisting of a polyimide film 1, a first adhesive layer 2, a second adhesive layer 3, an aluminum foil layer 4 and a thermoplastic resin unstretched film 5. The aluminum foil layer has On two opposite surfaces, the first adhesive layer and the second adhesive layer are respectively adhered to the two opposite surfaces of the aluminum foil layer, and the polyimide film is adhered to the first adhesive layer Above, the thermoplastic resin unstretched film is adhered to the second adhesive layer, and the total thickness of the battery flexible packaging material is 110 to 130 microns.

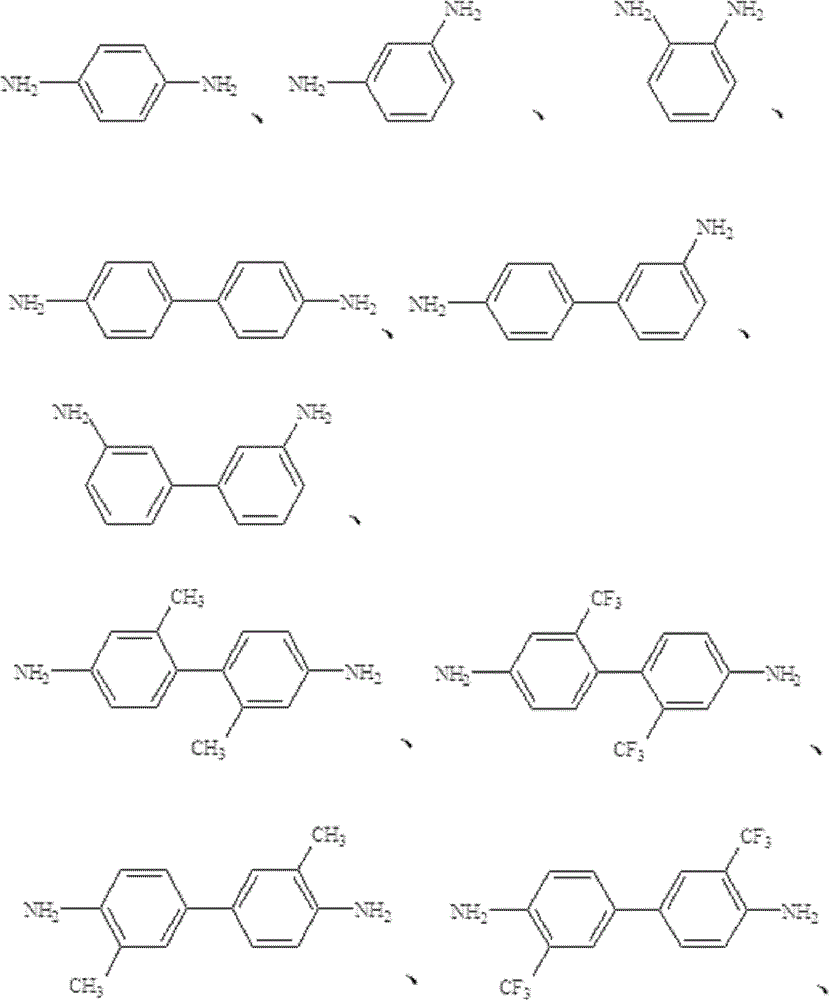

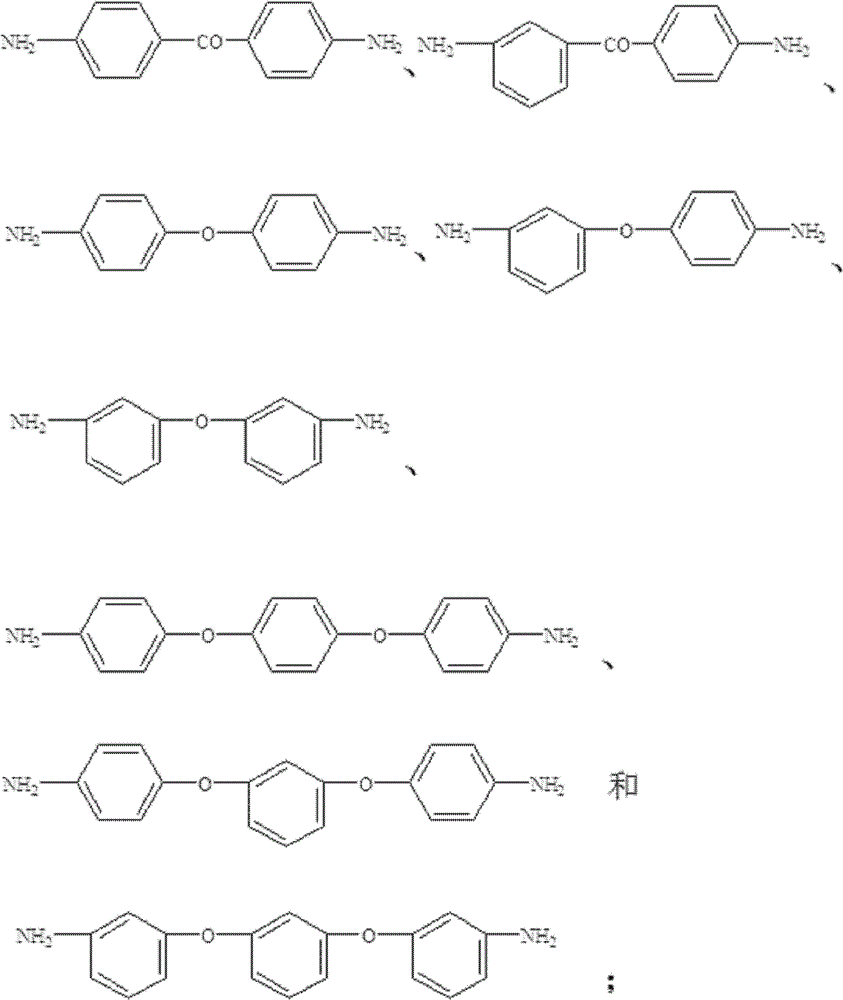

[0033] The polyimide film used in this embodiment is mainly composed of the dianhydride monomer 3,3',4,4'-biphenyltetracarboxylic dianhydride (3,3',4,4'-Biphenyltetracarboxylicdianhydride; BTDA) ( 0.7kmol) and 4,4'-Oxydiphthalicanhydride (4,4'-Oxydiphthalicanhydride; ODPA) (0.3kmol) and diamine monomer 1,3'-bis(3-aminophenoxy)benzene (1,3'-Bi...

Embodiment 2

[0036] Embodiment 2: The structure of the flexible battery packaging material of this embodiment is the same as that of Embodiment 1.

[0037] The polyimide film used in this embodiment is mainly composed of dianhydride monomers BTDA (0.7kmol) and ODPA (0.3kmol) and diamine monomers APB-133 (0.8kmol) and 3,4′-Diaminobenzophenone (0.2 kmol) copolymerized polyimide film made by copolymerization; its thickness is 20 microns, and the density is 1443kg / m 3 ; And then apply this copolymerized polyimide film to the battery flexible packaging material.

[0038] The process steps of the battery flexible packaging material of this embodiment are the same as the process steps of the first embodiment.

Embodiment 3

[0039] Embodiment 3: The structure of the flexible battery packaging material of this embodiment is the same as that of Embodiment 1.

[0040] The polyimide film used in this embodiment is mainly composed of dianhydride monomers BTDA (0.7kmol) and ODPA (0.3kmol) and diamine monomers APB-133 (0.75kmol) and 3,4'-Diaminobenzophenone (0.25 kmol) a copolymerized polyimide film formed by copolymerization; its thickness is 25 microns, and the density is 1447kg / m 3 ; And then apply this copolymerized polyimide film to the battery flexible packaging material.

[0041] The process steps of the battery flexible packaging material of this embodiment are the same as the process steps of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com