Winding preventing device for rotation joint of robot

An anti-winding and robot technology, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of high installation cost, damage to the cable structure, unrealistic and other problems, and achieve the effect that is not easy to observe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

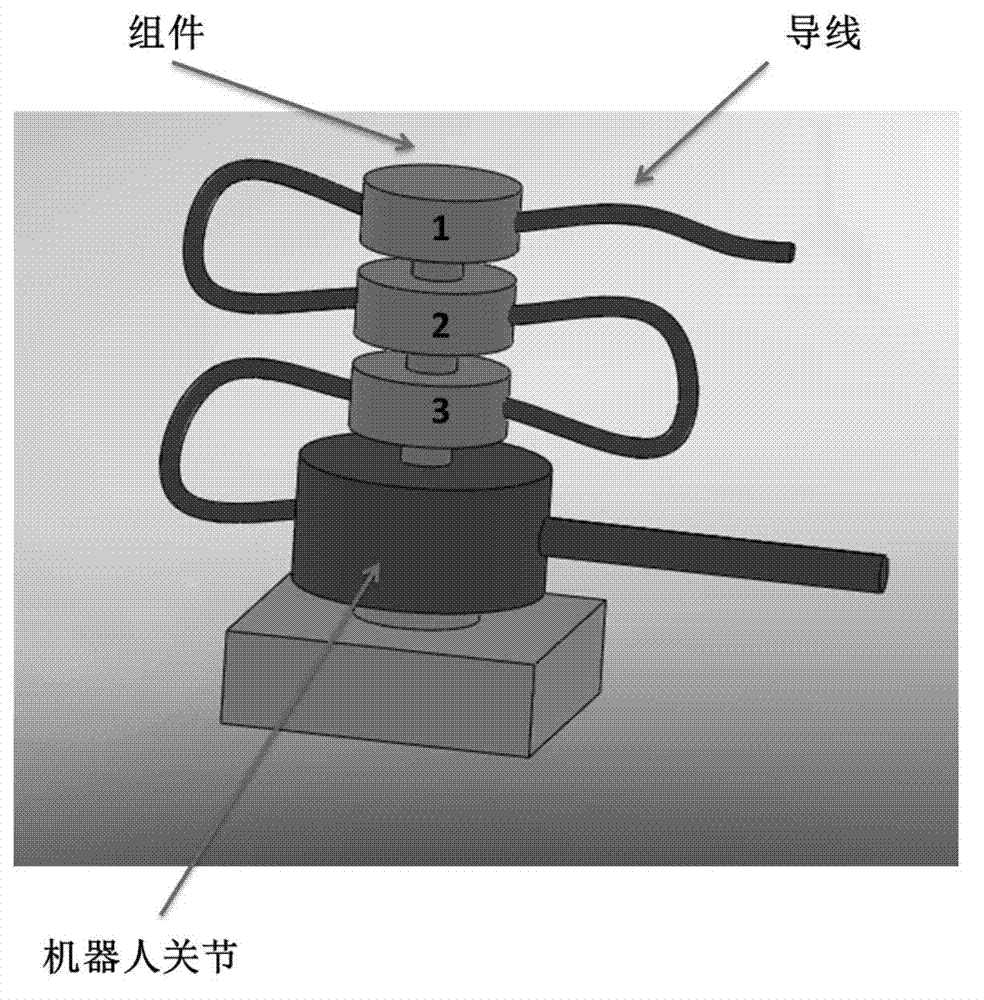

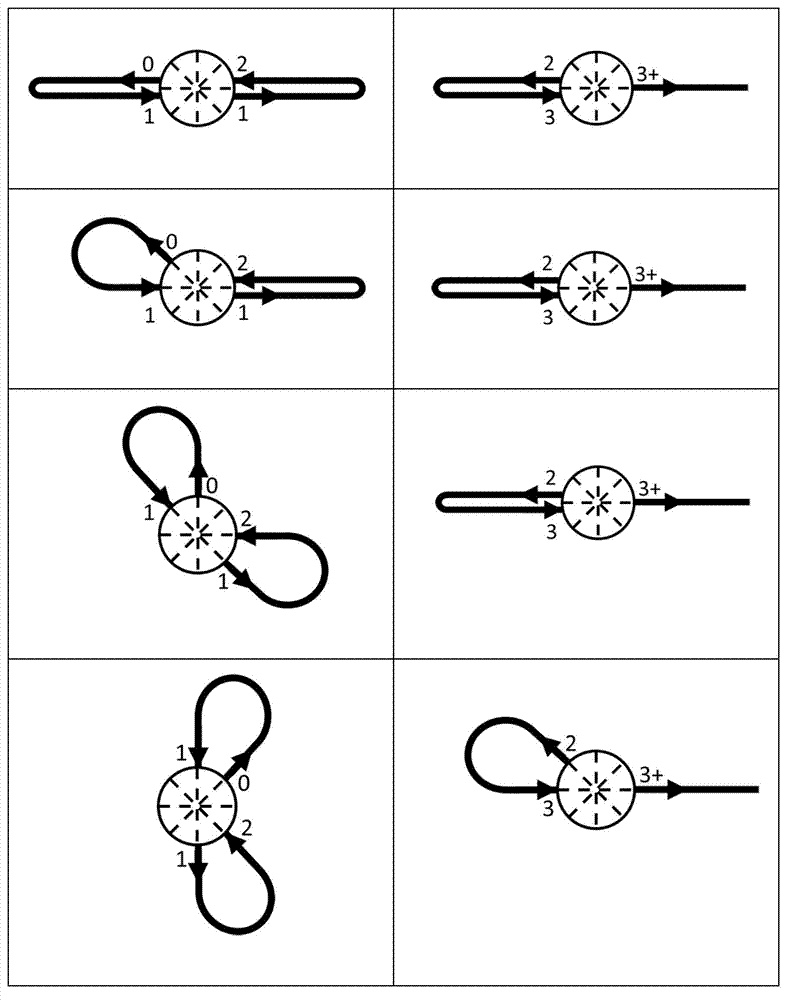

[0037] The anti-winding device includes several passive rotating components and requires a certain length of cables. Several components can be superimposed as needed, and generally no less than 3 components are used. Typical use cases like figure 1 shown.

[0038] passive rotating assembly

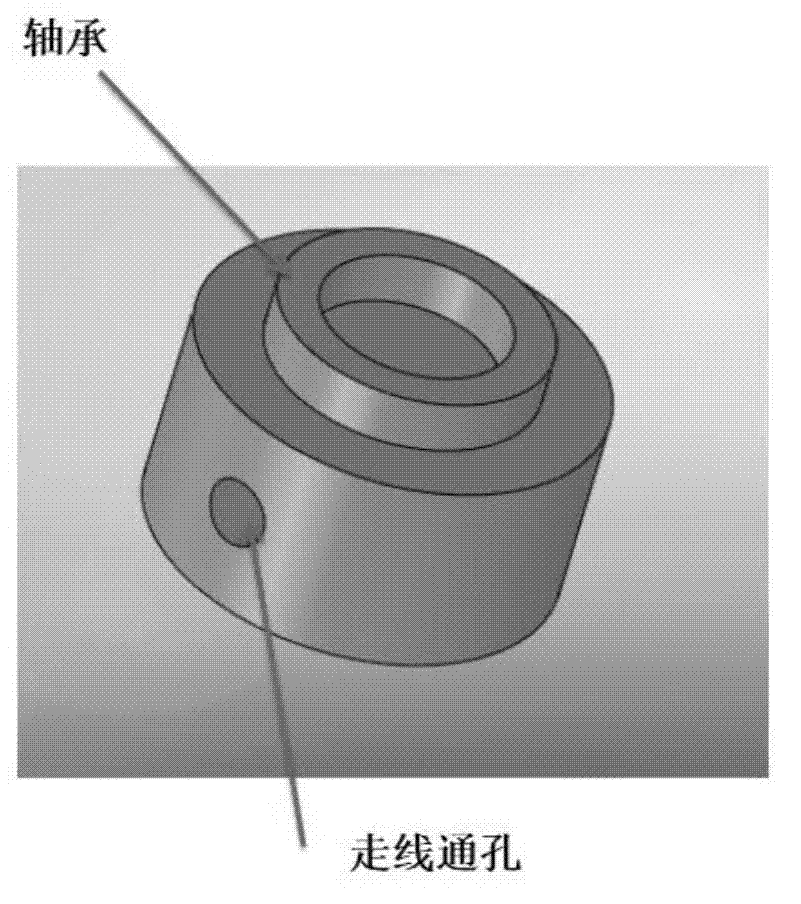

[0039] The passive rotating assembly is the core part of the present invention. The component is connected with the joint of the robot, and the connected component 1 is fixed at the joint of the robot, and there is a corresponding mechanical structure to ensure that the two components do not disengage. The mutual rotation between the two is guaranteed to be smooth by means of lubrication or bearing connection. If the joints of the robot are inconvenient to change, the component 1 can also be fixed on the joints of the robot so that they cannot move relative to each other. The cables that need to rotate with the joint pass through the component through the through hole in the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com