Functional microbe embedded slow-release composite filling material and preparation method thereof

A technology of functional microorganisms and composite fillers, which is applied in the field of air pollution control and environmental protection, can solve the problems of lack of slow release and easy leaching of nutrients, and achieve the effects of low raw material cost, simple manufacturing process, and shortened film-hanging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

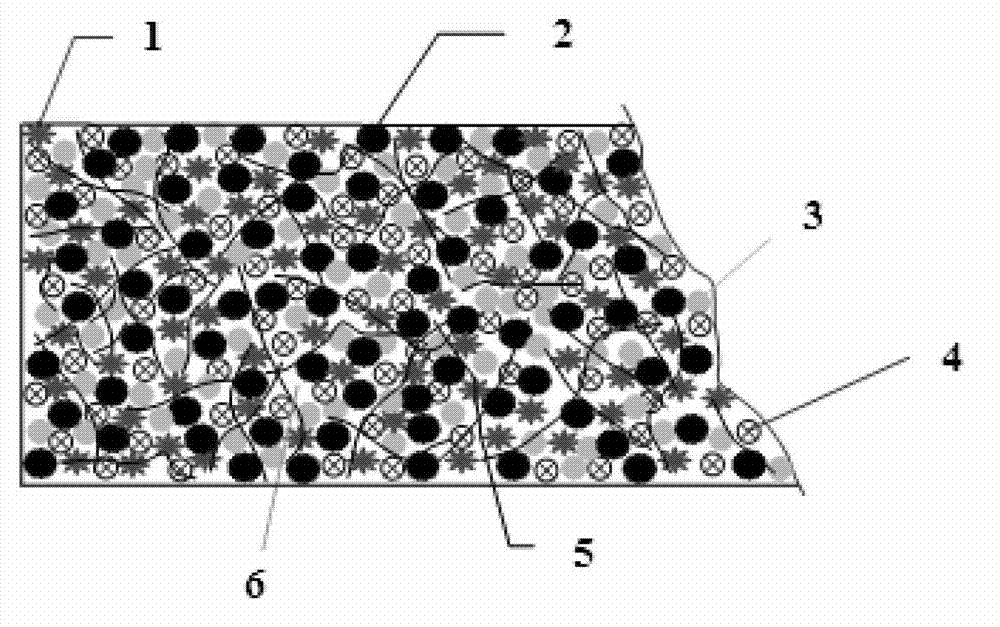

[0027] The embedded functional microbial slow-release composite filler provided in this embodiment consists of the following raw materials in parts by weight: 15 parts of functional microbial carrier, 5 parts of decomposed sawdust, 20 parts of perlite, 15 parts of calcium carbonate, 18 parts of cement, 1 part of kaolin, 25 parts of 5% water glass.

[0028] The preparation method of the embedded functional microbial slow-release composite filler provided in this example comprises the following steps:

[0029] 1. Preparation of functional microbial carrier:

[0030] 1) Preparation of raw materials:

[0031] a) Use traditional technology and modern biotechnology to screen out various bacterial species with particularly strong affinity for odor molecules, and modify and regulate the structure of the bacterial community to increase their degradation rate and expand the scope of degradation substrates, so as to obtain energy Microbial strains that efficiently degrade pollutants in...

Embodiment 2

[0040] The embedded functional microbial slow-release composite filler provided in this embodiment includes the following raw materials in parts by weight: 25 parts of functional microbial carrier, 7 parts of decomposed peanut shell fine powder, 15 parts of perlite, 10 parts of calcium carbonate, and 20 parts of cement. 3 parts, 3 parts of kaolin, 30 parts of 5% water glass.

[0041] The preparation method of the embedded functional microbial slow-release composite filler provided in this example comprises the following steps:

[0042] 1. Preparation of functional microbial carrier:

[0043] 1) Preparation of raw materials:

[0044] a) Use traditional technology and modern biotechnology to screen out various bacterial species with particularly strong affinity for odor molecules, and modify and regulate the structure of the bacterial community to increase their degradation rate and expand the scope of degradation substrates, so as to obtain energy Microbial strains that effic...

Embodiment 3

[0051] The embedded functional microbial slow-release composite filler provided in this embodiment includes the following raw materials in parts by weight: 20 parts of functional microbial carrier, 10 parts of decomposed sawdust, 17 parts of perlite, 20 parts of calcium carbonate, 15 parts of cement, kaolin 5 parts, 35 parts of 5% water glass.

[0052] The preparation method of the embedded functional microbial slow-release composite filler provided in this example comprises the following steps:

[0053] 1. Preparation of functional microbial carrier:

[0054] 1) Preparation of raw materials:

[0055] a) Use traditional technology and modern biotechnology to screen out various bacterial species with particularly strong affinity for odor molecules, and modify and regulate the structure of the bacterial community to increase their degradation rate and expand the scope of degradation substrates, so as to obtain energy Microbial strains that efficiently degrade pollutants in mal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com