Energy-saving baking room with dehumidifying and heat accumulating function

A technology of barn and moisture outlet, which is applied in the field of energy-saving barn, which can solve the problems of high smoke density, prolonged dehumidification time, and energy waste, so as to reduce heat waste, improve heat energy utilization rate, and shorten dehumidification time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

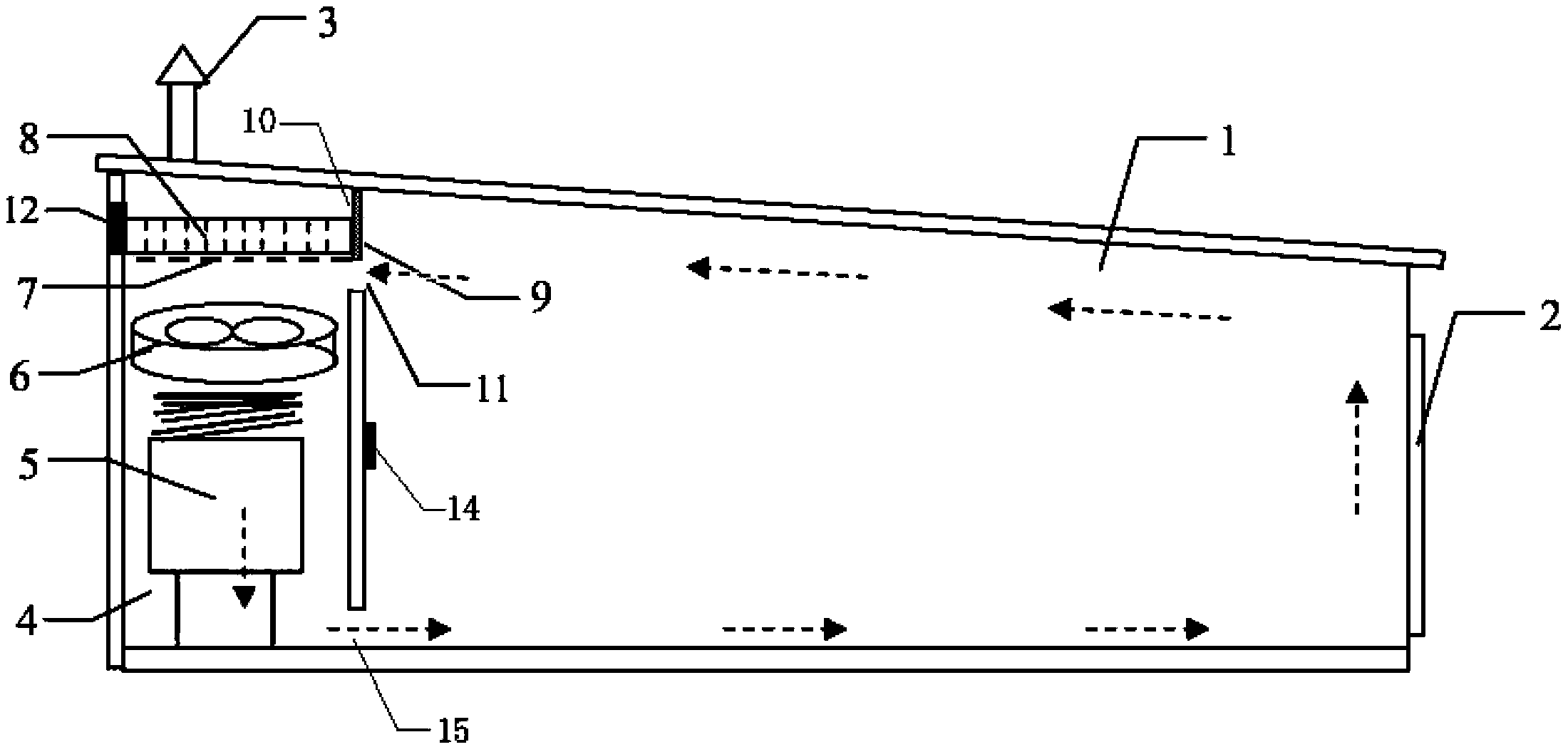

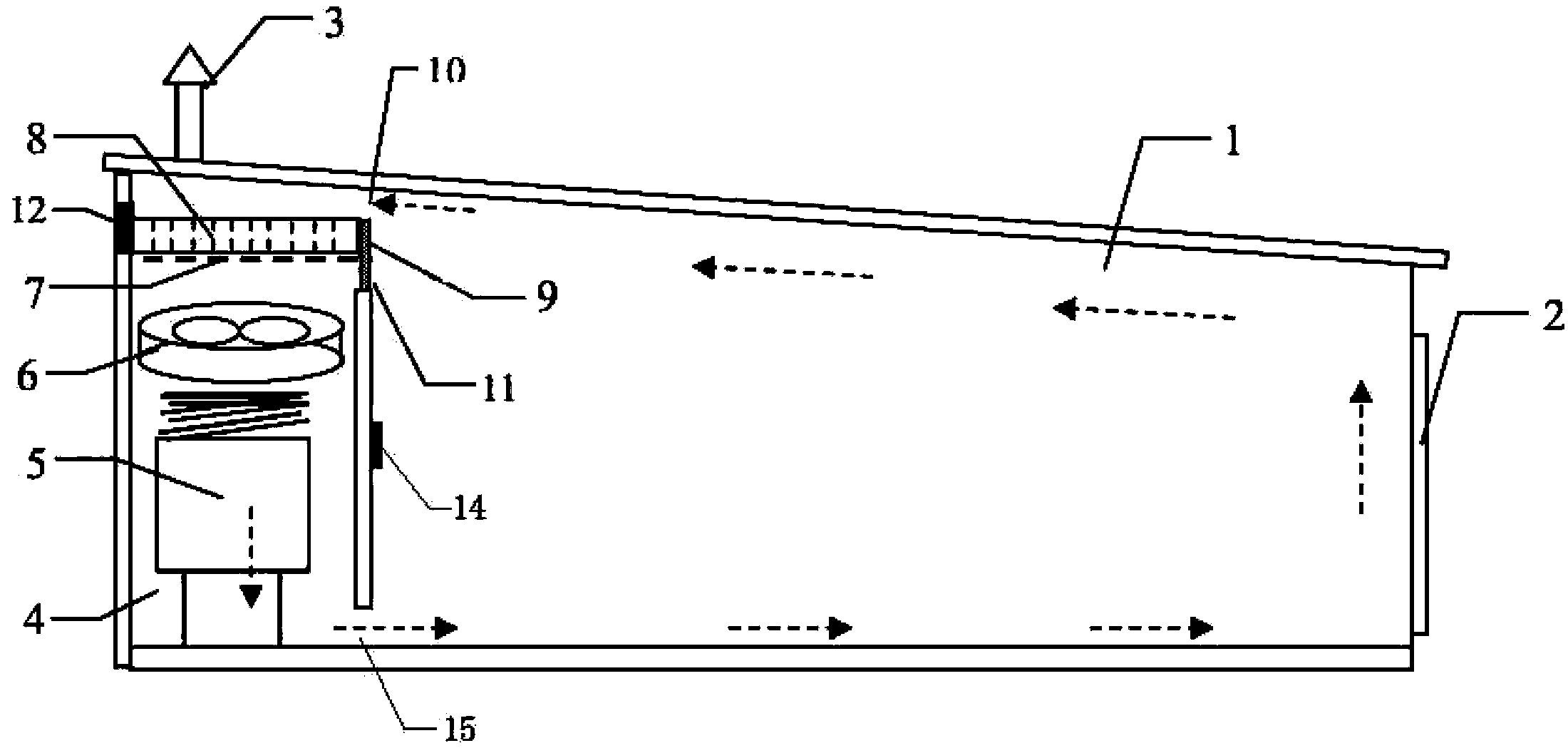

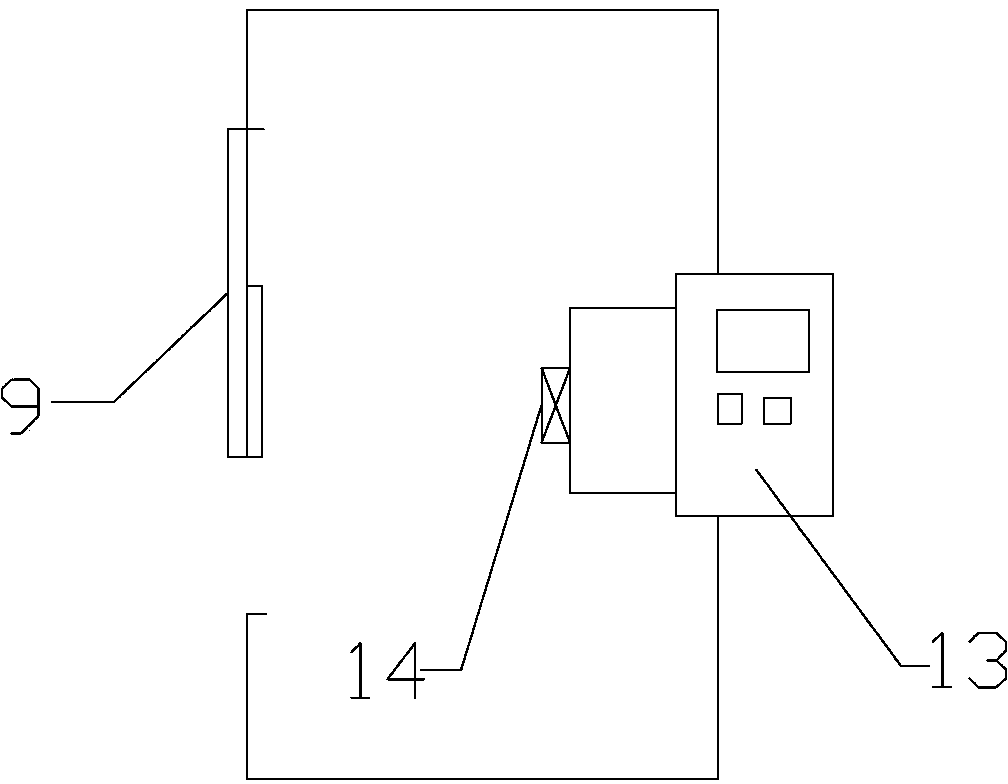

[0021] The present invention will be further described below in conjunction with accompanying drawing. figure 1 Among them, the energy-saving barn for dehumidification and heat retention includes a baking room 1 and a heating room 4, a moisture outlet is opened on the baking room 1, a chimney 3 is provided on the heating room 4, and a heating room 4 is provided with The heating furnace 5 and the fan 6 are provided with an air return port 11 and a moisture discharge port 10 between the heating chamber and the baking chamber. Between the baking room and the position higher than the air return port 11, in order to facilitate the air circulation and dehumidification, the moisture discharge port 10 is set near the top of the baking room. The position adjacent to the wet port 10, the distance between the two openings is equal to the height of the moisture discharge device; the moisture absorption device is composed of a porous support plate 7 and a moisture absorption plate 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com