Formula, preparation method and application thereof of fruit freshness-retaining wax

A fruit wax and fruit technology, which is applied to the preparation of fruit wax for preservation of fruit, the application of fruit wax for preservation of fruit, and the field of fruit wax for preservation of fruit, can solve the problems of reducing the accumulation of odorous substances, and achieves extended shelf life, low distiller's grains smell, and coating. Effect of membrane consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

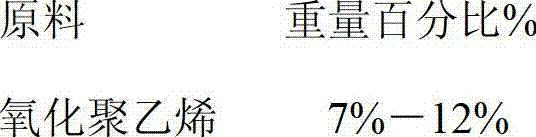

[0035]A fruit wax for preserving freshness, which is prepared from the following raw materials: oxidized polyethylene AC629 (Honeywell, USA), candelilla wax (Suzhou Yushiji Biotechnology Co., Ltd.), morpholine (BASF, Germany), Oleic acid (Sinopharm Chemical Reagent Co., Ltd.), myristic acid (Tyco Palm Chemicals (Zhangjiagang) Co., Ltd.), polydimethylsiloxane (Changzhou Dow Chemical Co., Ltd.), glycerol (Sinopharm Chemical Reagent Co., Ltd. company), potassium hydroxide (Sinopharm Chemical Reagent Co., Ltd.), deionized water.

[0036] Unit: mass percentage

[0037]

Embodiment 11

[0039] A preparation method for fruit fresh-keeping fruit wax, it comprises the steps:

[0040] (1), choose fresh-keeping fruit wax raw materials: select and weigh each component described in any group in Examples 1 to 10;

[0041] (2) Adding raw materials: using phase inversion emulsification method, oxidized polyethylene, candelilla wax, oleic acid, myristic acid, morpholine, potassium hydroxide, glycerol, polydimethylsiloxane, a small part The raw material of deionized water (about 1 / 3 oxidized polyethylene and candelilla wax weight) is dropped in the reactor;

[0042] (3) The filler is heated and melted: heat and melt at 110-120°C and stir evenly, the stirring speed is 200-400r / min, and the stirring and emulsifying time is about 20-30min, forming a W / O emulsion;

[0043] (4) Add water: Slowly add deionized water above 90°C during the stirring process, after phase inversion to form an O / W emulsion, add the remaining deionized water above 90°C quickly, and finally cool down...

Embodiment 12

[0047] After artificial dipping and waxing of the present invention, summer oranges were stored at room temperature at 20°C and 70-75%RH for 3 weeks, the weight loss rate was 3.36%, the soluble solids were 10.8%, the titratable acid was 0.57%, and the Vc content was 61.7mg / 100g, ethanol content is 1144.6μl / L, which is significantly lower than 1500μl / L, acetaldehyde content is 16.4μl / L, methanol content is 82.4μl / L, and the imported commercial wax Xianliang 402D is widely used in China. After summer orange, the weight loss rate is 5.97%, the soluble solid content is 11.4%, the titratable acid is 0.62%, Vc58.3mg / 100g, the ethanol content is 1199.7μl / L after one week, the content is as high as 7943μl / L after three weeks, and the acetaldehyde content is 58.7μl / L methanol content was 134.3μl / L. The above results show that after the orange fruit is treated by the present invention, the content of the peculiar smell substances is low, water retention and freshness are preserved, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com