Over-current protection circuit of light-emitting diode (LED) constant-current driving circuit

An over-current protection circuit and constant-current drive technology, applied in over-current protection, lamp circuit layout, electric light source, etc., can solve problems affecting circuit performance, white light color shift, affecting luminous flux output, and luminous brightness Changes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

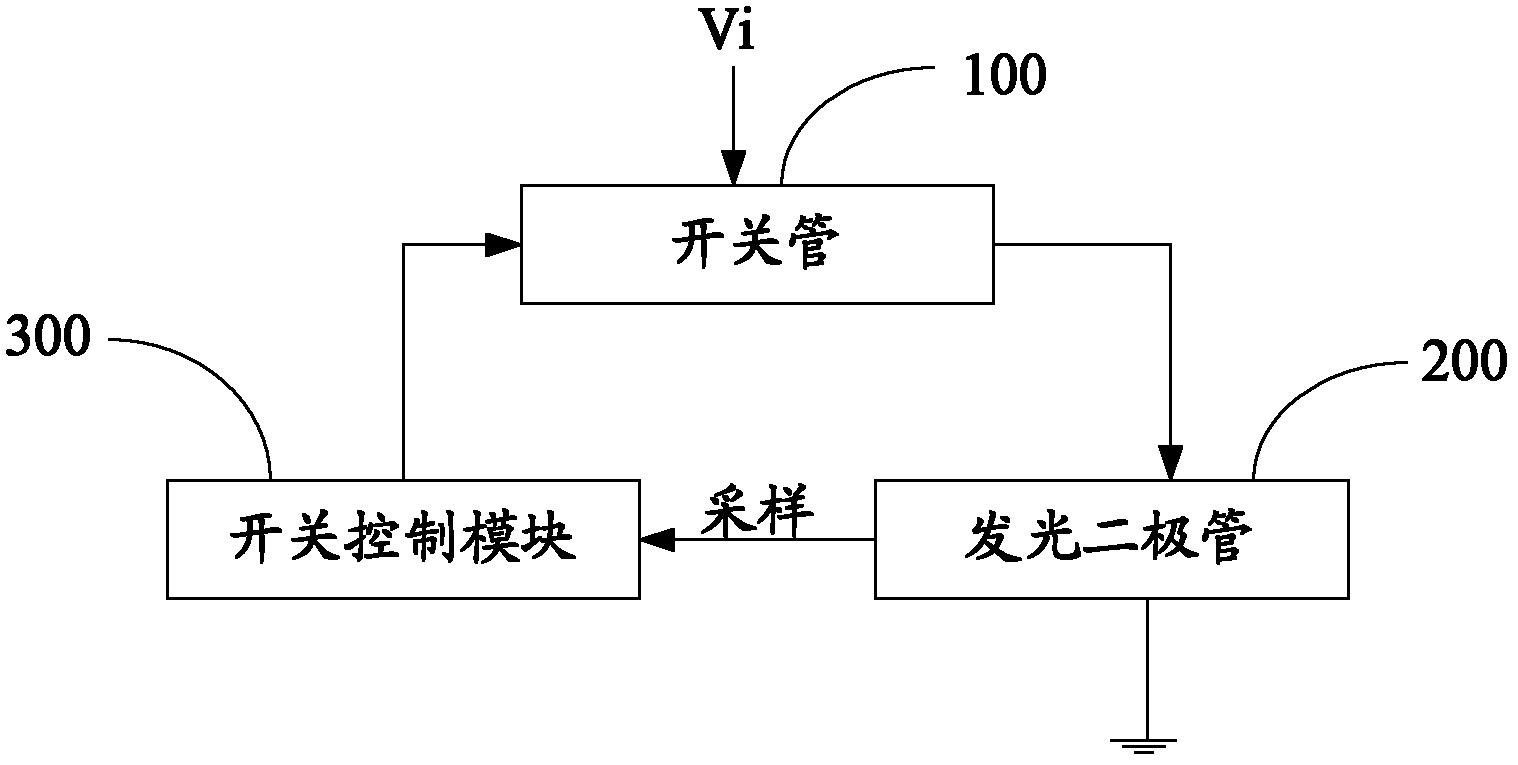

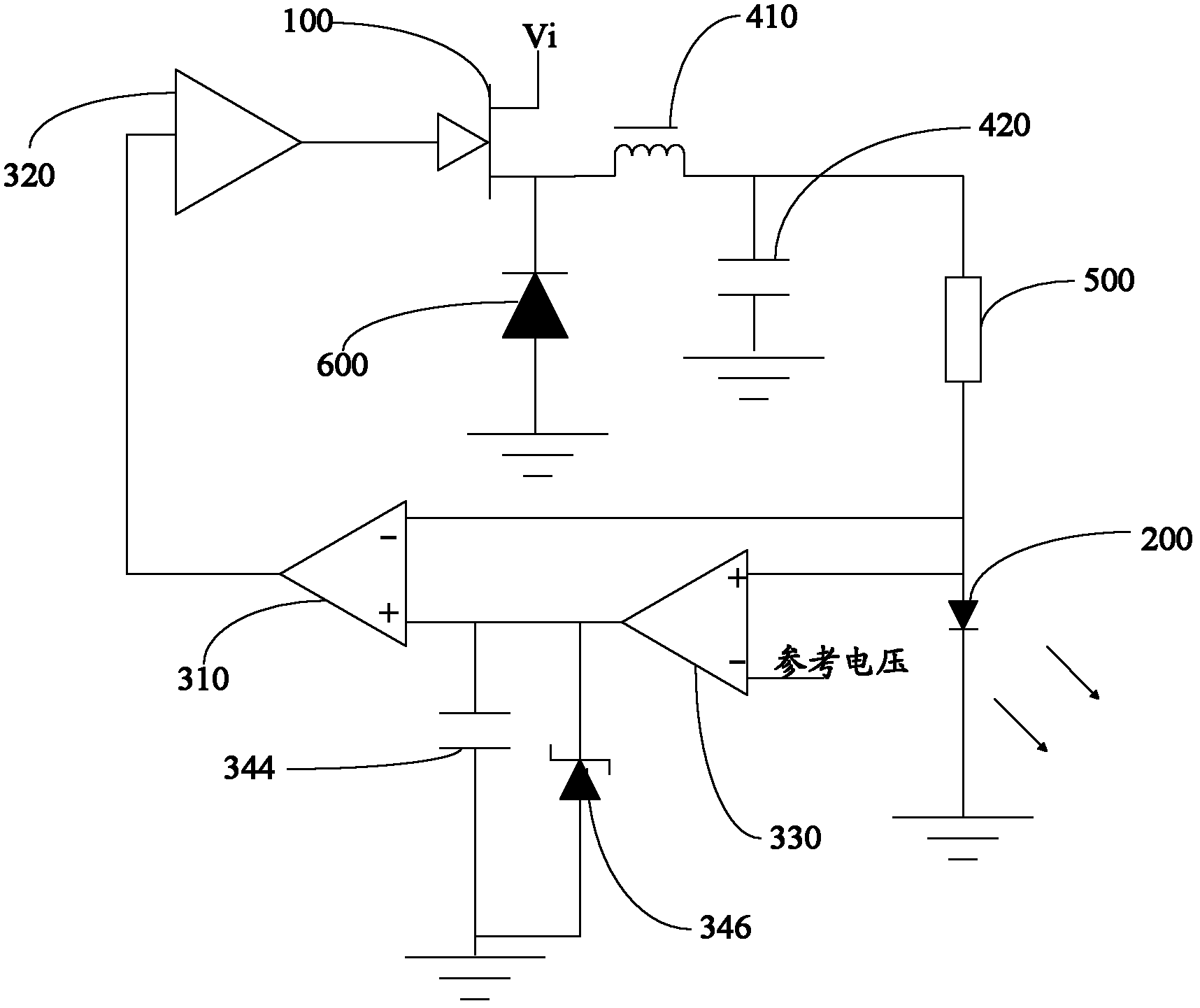

[0027] Such as figure 1 Shown is a schematic structural diagram of the overcurrent protection circuit of the LED constant current drive circuit. The overcurrent protection circuit of the LED constant current drive circuit is used for overcurrent protection of the constant current drive LED drive circuit. The overcurrent protection circuit includes a switch tube 100 connected in series with the light emitting diode 200. The switch tube 100 is a three-terminal switching device, including two access terminals and a control terminal. The switch tube 100 is connected in series with the light emitting diode 200 through two access terminals. catch.

[0028] The overcurrent protection circuit also includes a switch control module 300 , the input terminal of the switch control module 300 samples the working voltage of the LED 200 , and the output terminal is electrically connected to the control terminal of the switch tube 100 . The switch control module 300 controls the switching of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com