Drilling control and data collection system of self-elevating platform

A technology of data acquisition system and self-elevating platform, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc. The effect of strong operability and working comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

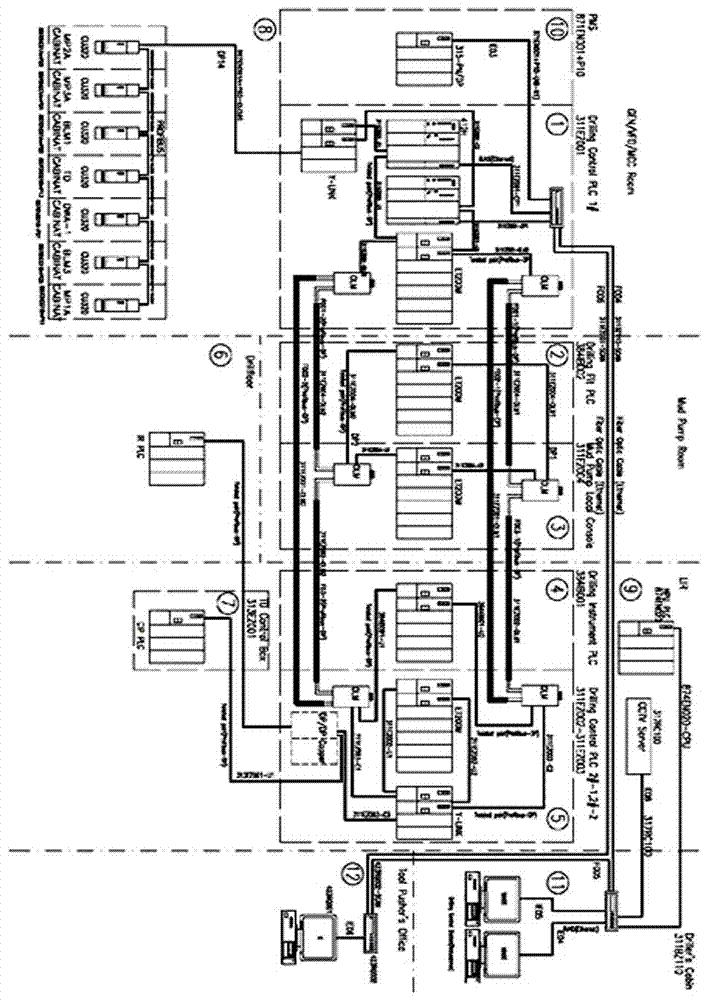

[0020] Jack-up platform drilling control and data acquisition system, which is a control and data acquisition system based on redundant programmable logic controller (PLC), through the use of the driller to control the overall control of the industrial computer 12, the data A control and data acquisition system realized by conversion and information transmission of network switches.

[0021] Such as figure 1 As shown, the 412H processor communicates with the main hull equipment substation drilling PLC (1) using PROFIBUS DP; the main hull equipment drilling PLC (1) controls the main hull drilling equipment and collects data; mud pool PLC2, mud pump operation console PLC3, Drilling instrument PLC4 and drill floor control equipment PLC5 are respectively arranged in their respective areas. They collect data from the field devices in their respective areas, and communicate with the CPU processor in the PLC master station through the photoelectric conversion module.

[0022] Drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com