Selective catalytic reduction (SCR) system with external mixing nozzle metering structure

A technology of SCR system and mixing nozzle, which is applied in the field of SCR system, can solve the problems of metering valve exhaust pipe burnout, high pressure control requirements, poor atomization effect, etc., and achieve good atomization mixing effect, high integration, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the preferred embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

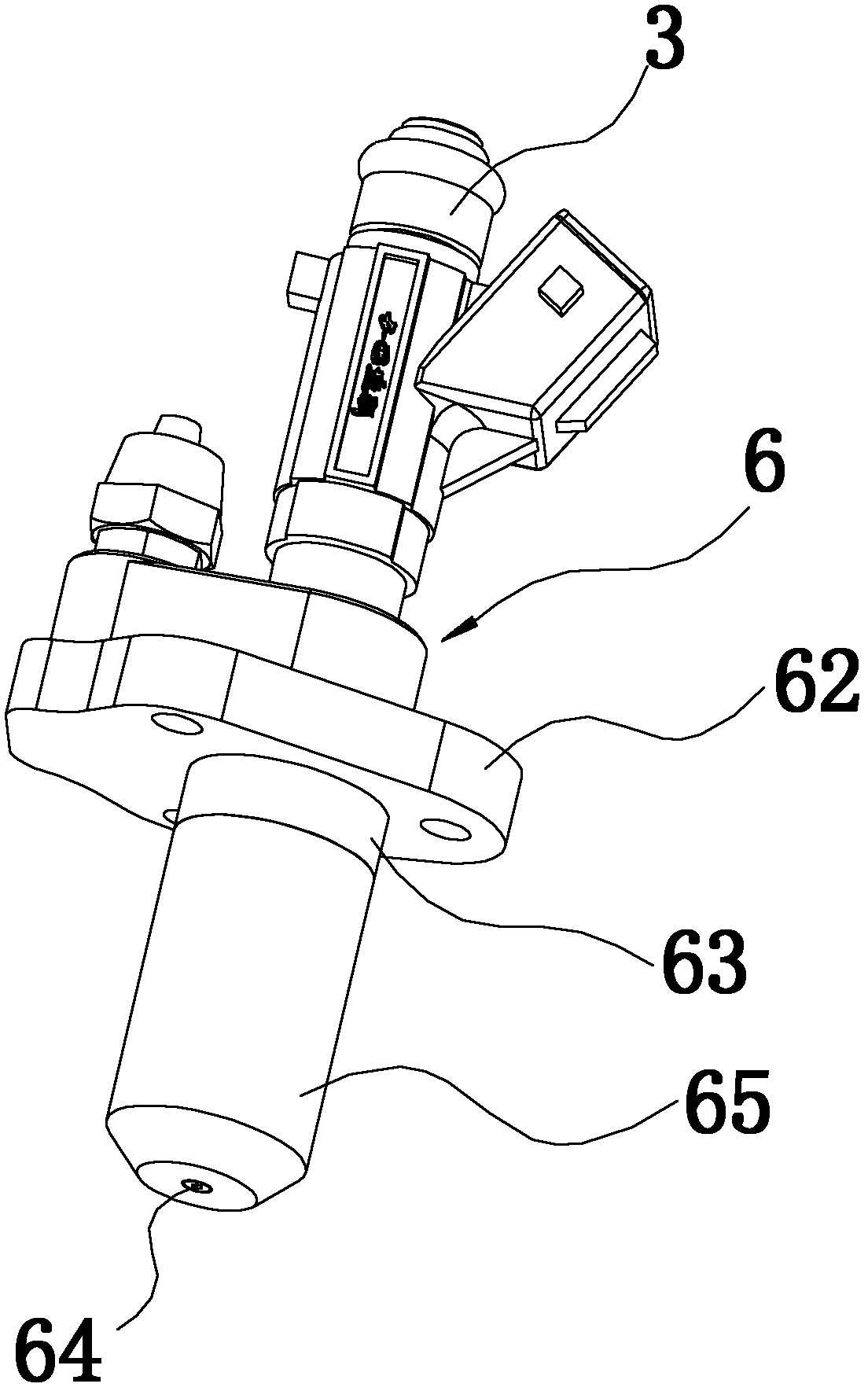

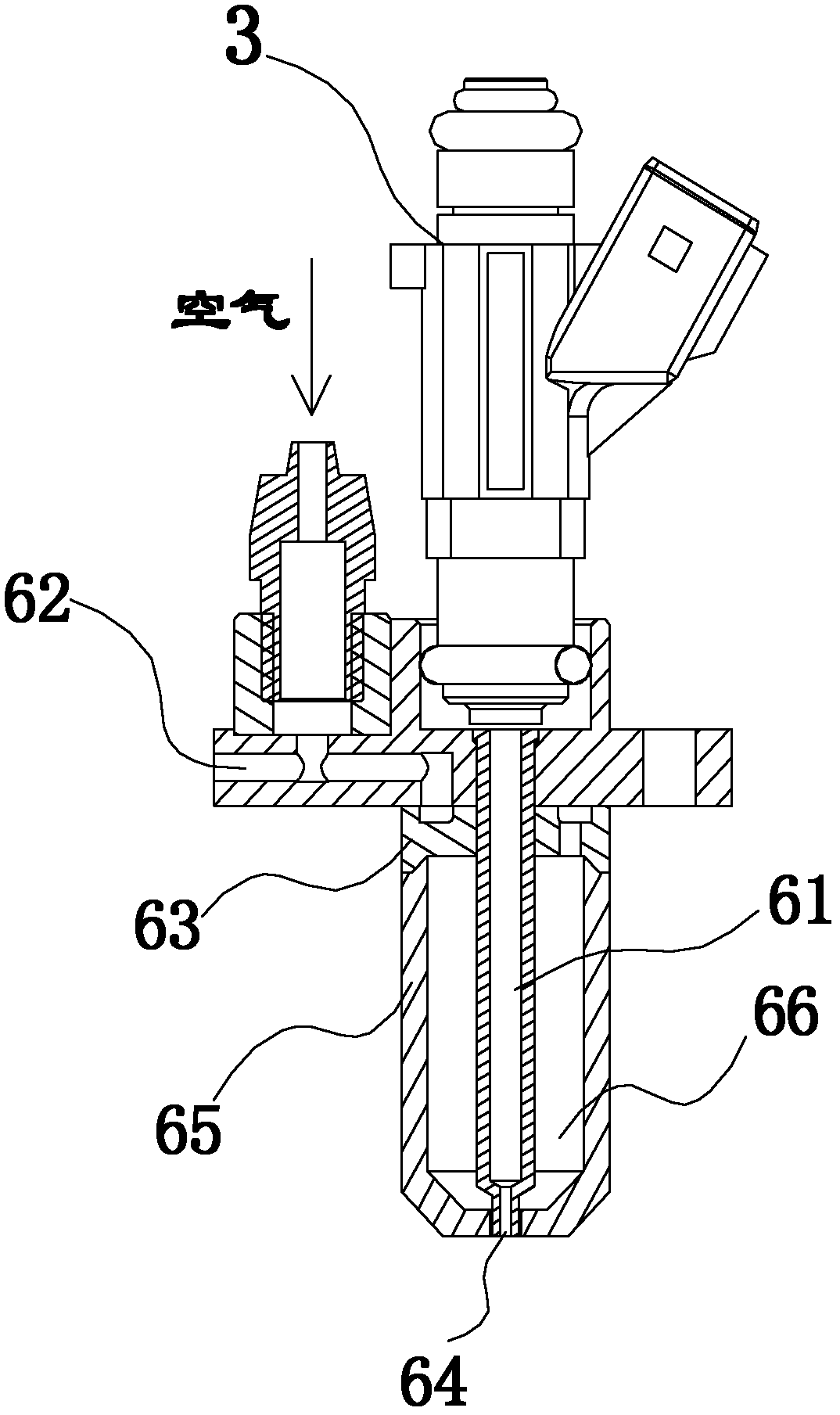

[0018] like figure 1 As shown, the present invention has an SCR system with an external mixing nozzle metering structure, including a urea tank 1, a urea pump 2, a pressure regulating valve 5, a sensor 14, a metering valve 3 and a nozzle 6, the urea pump 2, the pressure regulating valve 5, The filter 12, the sensor 14, the metering valve 3 and the nozzle 6 are sequentially connected in series. The urea pump 2 pumps the reducing agent stored in the urea tank 1 to the inlet of the metering valve 3, and the metering valve 3 accurately measures and injects the reducing agent. Then, the nozzle 6 installed directly on the exhaust pipe 15 is sprayed into the exhaust pipe 15. The pressure regulating valve 5 can stabilize the pressure upstream of the metering valve and prevent pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com