Heat-preserving cast-in-situ stripe for sintered shale heat-preserving hollow building block wall body

A hollow block and cast-in-place belt technology, which is applied to walls, building components, buildings, etc., can solve the problems of difficult construction, insufficient structural guarantee performance, and poor cooperative working ability, and achieves enhanced integrity and thermal insulation performance. Wall shrinkage cracks, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] In order to illustrate the performance of the cast-in-place tape of the present invention, the inventor built a new type of sintered shale heat-insulating hollow block wall with the heat-preservation cast-in-place tape of the present invention, and built an ordinary new type of sintered shale heat-preservation hollow block wall block wall, and conducted a thermal performance test study. The specific process is as follows:

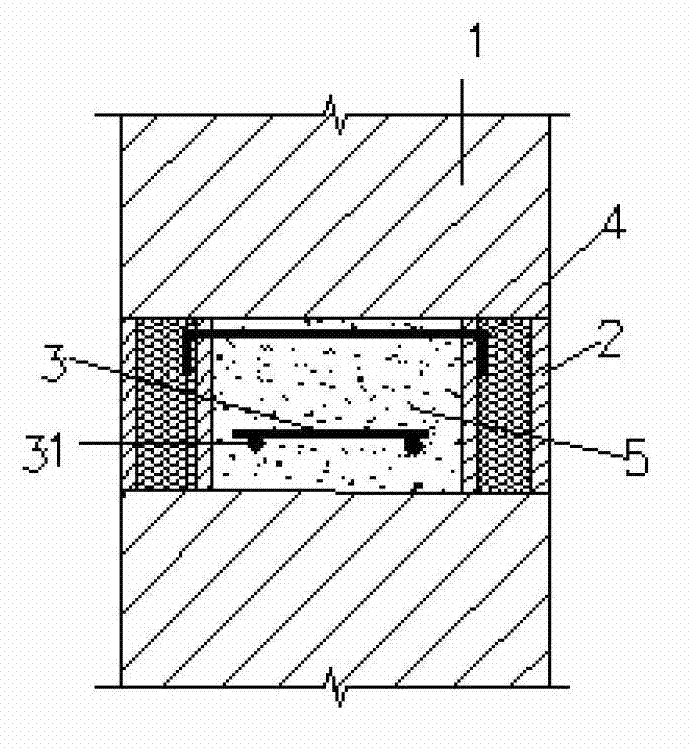

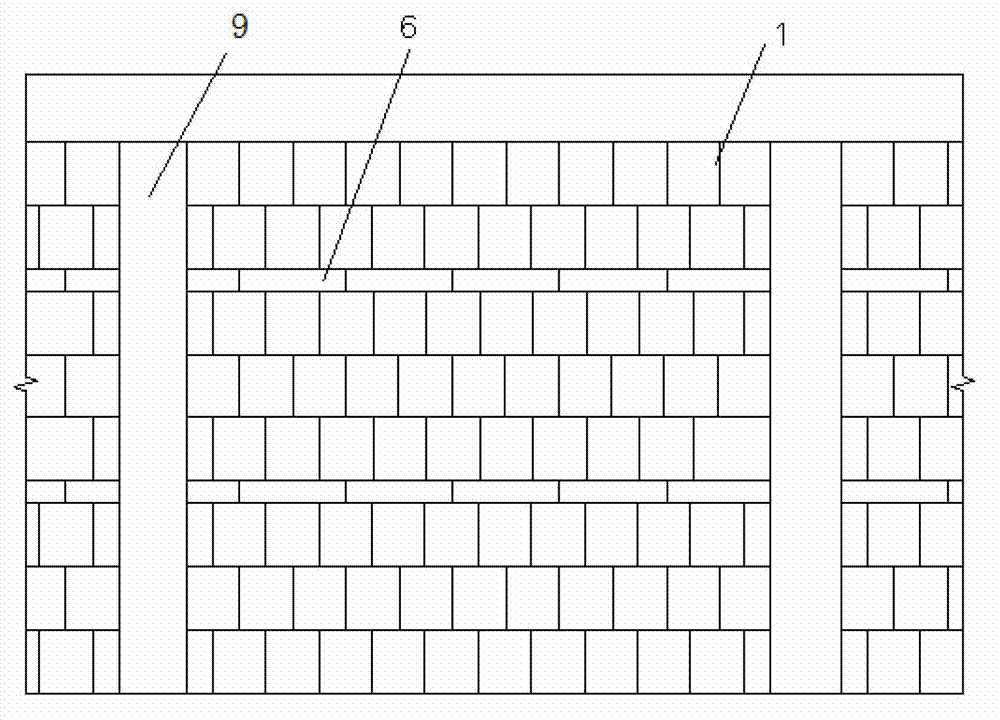

[0027] During the construction, the main wall 1 is built with whole bricks, the wall thickness is 365mm, and the construction method is the sticky mortar method. At the cast-in-place belt part of the main wall 1, after cleaning the section of the lower wall, stick the special mortar with the new sintered shale insulation hollow block 2. Hollow blocks 2 are placed on the inside and outside sides of the upper section of the lower wall, so that the long sides and large faces of the new sintered shale thermal insulation hollow block blocks 2 are flush w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com