Fabrication method of heat insulating component

A technology for thermal insulation components and manufacturing methods, which is applied in thermal insulation, building components, manufacturing tools, etc., and can solve problems such as the generation of poisonous gas and smoke, low bonding strength of surface materials, insufficient thermal insulation and sound insulation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

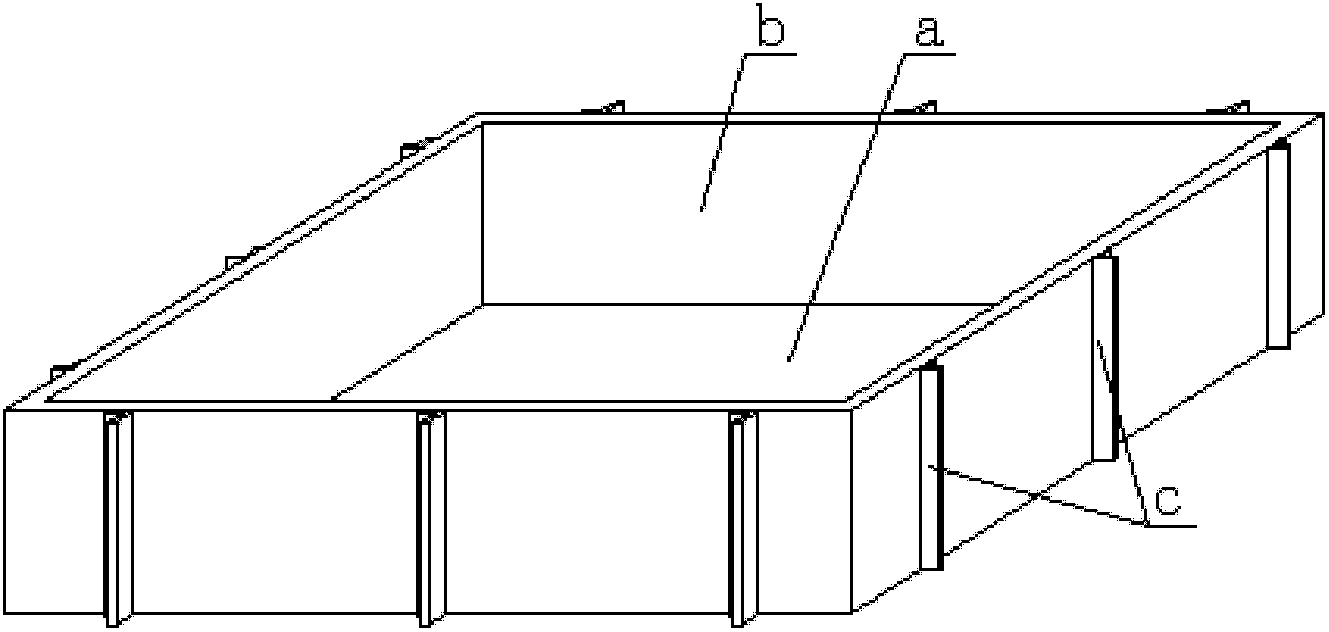

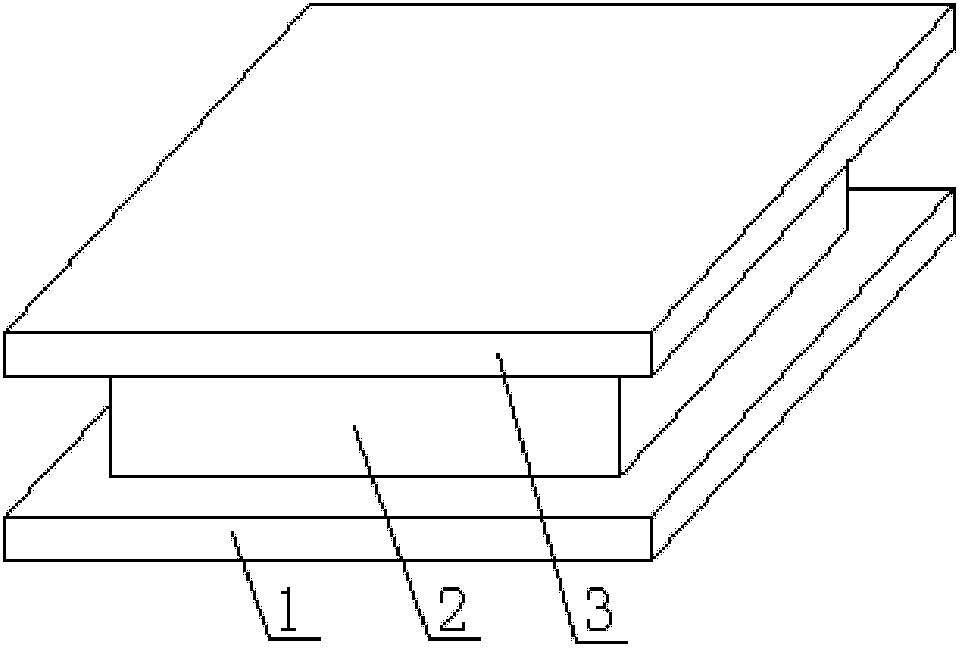

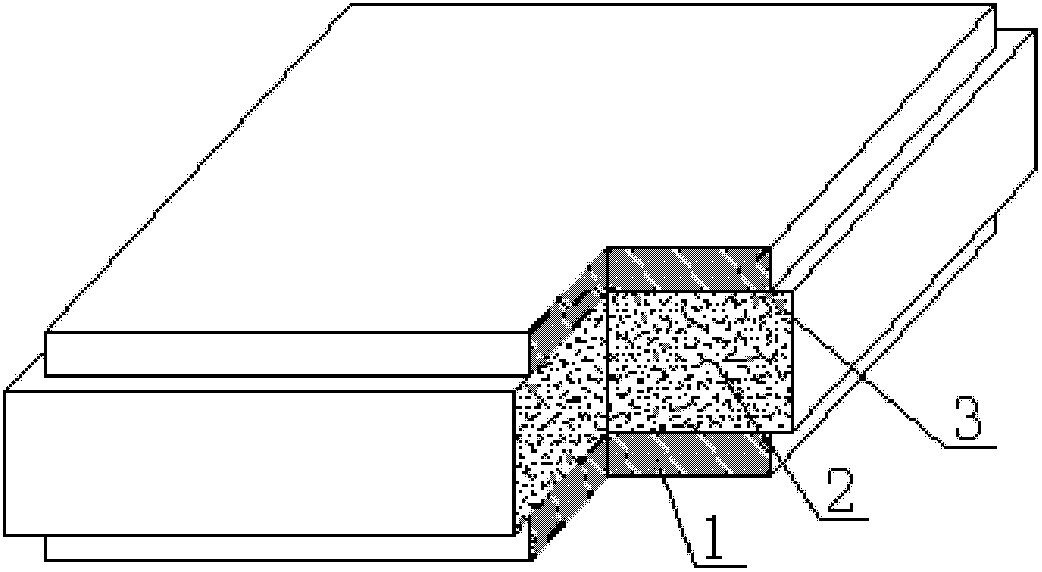

[0044] The technical solution of the present invention is: a method for making a thermal insulation component, which is characterized in that the lower hard board 1 is first poured on the template, and the thermal insulation layer 2 of the middle layer is poured with thermal insulation material before it hardens and condenses, and then poured again before it hardens and condenses The upper hard board 3 is demolded and maintained for molding. figure 1 It is a structural schematic diagram of the mold of the present invention, such as figure 1 The mold shown includes a bottom formwork a and a side formwork b, and each side formwork b is provided with three vertically arranged angle steel reinforcements c, such as figure 1 The mold shown is used for the production of thermal insulation components. The lower hard board 1 is poured on the bottom formwork a o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com