Correcting drill bit based on liquid support

A technology of liquid support and drill bit, which is applied in the direction of drill repair, drilling tool accessories, drilling/drilling equipment, etc., which can solve the problems of complex drilling process and achieve the effect of enhancing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

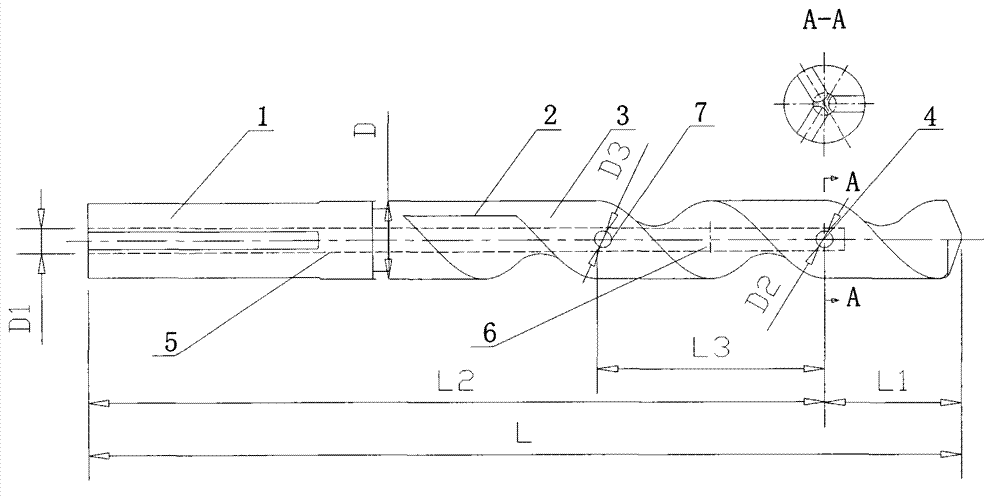

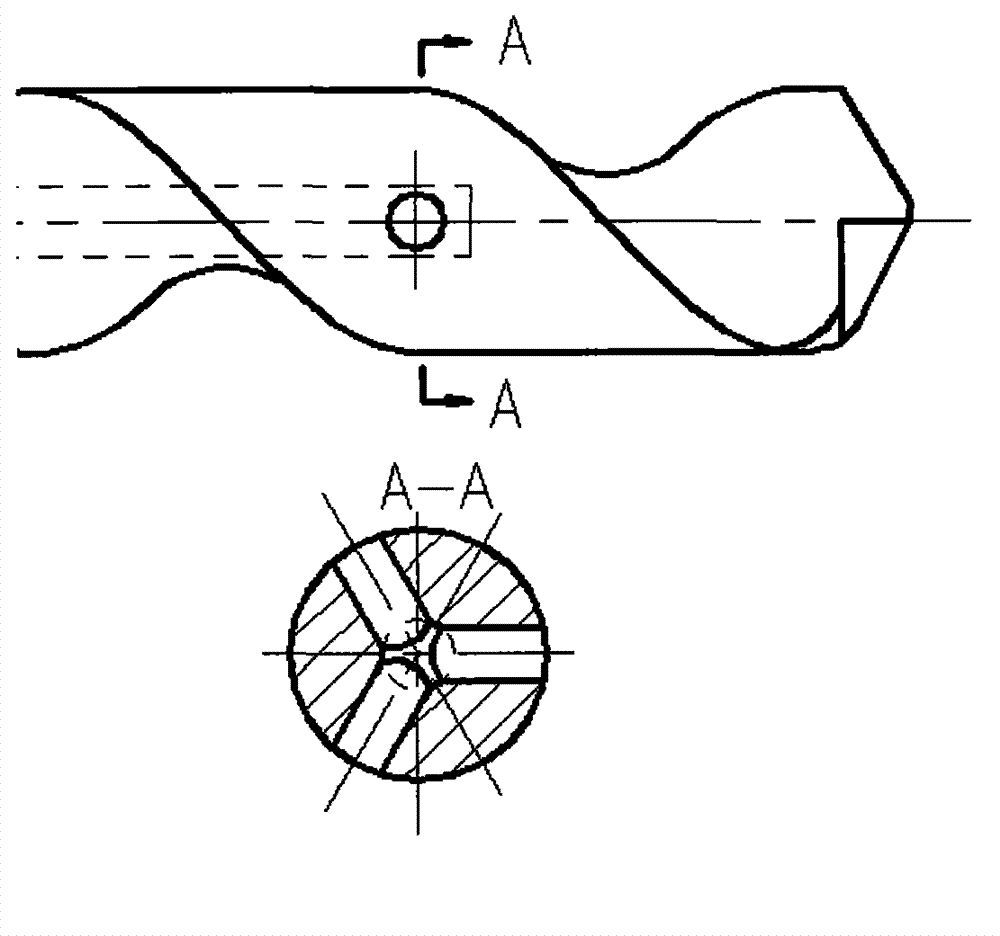

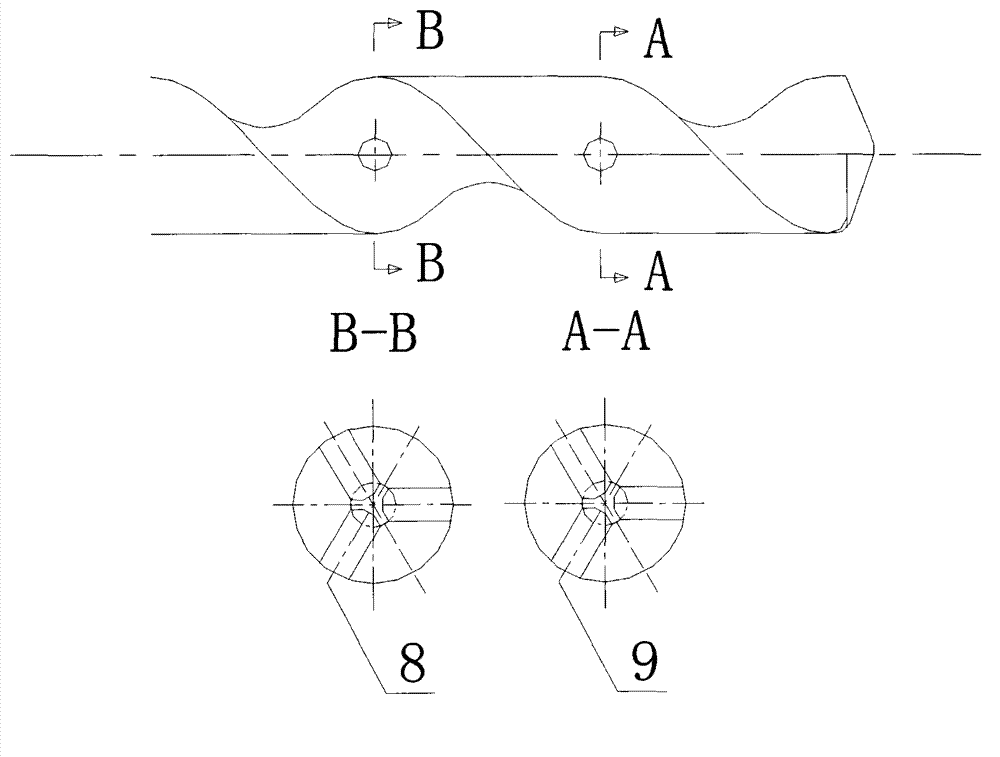

[0025] combined with figure 1 And attached figure 2 , a liquid-supported deviation-correcting drill bit, first drill a blind hole (5) through the coolant along the center line inside the drill bit, and drill the blind hole (5) through the coolant from the end of the drill shank (1), through The depth L2 of the blind hole (5) of the coolant is 80% to 90% of the total length L of the drill bit, and the diameter D1 of the blind hole (5) through the coolant is 10% to 15% of the diameter D of the drill bit. If D1 is greater than 1mm, then D1 is taken as 1 mm; on the cutting edge (3) of the drill blade (2), three evenly distributed microholes (4) are drilled radially evenly, and the axes of the three uniformly distributed microholes (4) are 120° to each other. Three evenly distributed micro-holes (4) are drilled to intersect with the blind hole (5) through which the coolant passes, and the distance L1 between the center of the three evenly distributed micro-holes (4) and the drill...

specific Embodiment approach

[0030] A deviation-correcting drill bit based on liquid support. First, a blind hole (5) through the coolant is drilled along the center line inside the drill bit. The blind hole (5) through the coolant is drilled from the end of the drill shank (1), and the coolant is passed through the hole. The depth L2 of the blind hole (5) of the liquid is 80% to 90% of the total length L of the drill bit, and the diameter D1 of the blind hole (5) through the coolant is 10% to 15% of the diameter D of the drill bit. If D1 is greater than 1mm, then D1 Take 1mm; on the cutting edge (3) of the drill blade (2), drill three evenly distributed microholes (4) in the radial direction, and the axes of the three uniformly distributed microholes (4) are 120° to each other, and the three A uniformly distributed microhole (4) is drilled to intersect with the blind hole (5) passing through the coolant, and the distance L1 between the center of the three uniformly distributed microholes (4) and the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com