Textile dust collection device

The technology of a dust suction device and a suction pipe is applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using gas flow, etc., which can solve the problems of easy clogging, high price, complex structure of dust removal devices, etc., and achieve easy clogging, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

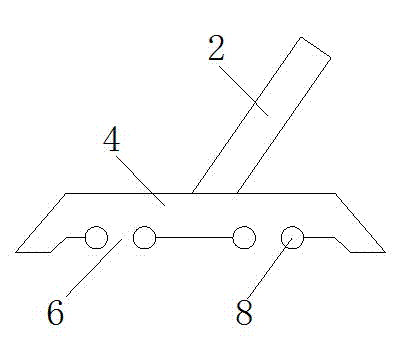

[0011] see figure 1 As shown, a textile vacuum device includes a suction pipe 2 and a suction head 4 installed at the end of the suction pipe 2. The suction head 4 has at least one rectangular vacuum suction port 6, and the edges of the vacuum suction port 6 are respectively provided with rotatable When in use, the roller 8 located at the edge of the vacuum suction port 6 rotates at a high speed, so that the cotton or fiber cannot be attached to the vacuum suction port 6, so it will not cause the cotton wool or fiber to gather at the vacuum suction port 6, so that it will not be blocked .

[0012] In order to prevent the generation of static electricity, a ceramic layer is arranged on the surface of the roller 8 .

[0013] To sum up, the present invention has a simple structure and is not easy to be blocked.

[0014] The above descriptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com