Tripod constant velocity joint

A constant velocity universal joint, three-pin technology, applied in elastic couplings, mechanical equipment, couplings, etc., can solve the problems of poor noise and vibration characteristics, complicated assembly of retaining rings, etc., to reduce amplitude, Improved service life and high operating quietness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] exist image 3 The three-pin constant velocity joint 1 shown in radial cross-section has an outer joint part 2 and an inner joint part 3 arranged inside a hollow cavity 4 of the outer joint part 2, the joint The external part has a central hollow space 4 and three recesses 5 emanating from this hollow space 4 and arranged evenly distributed on the peripheral side, the recesses each having two axially parallel and parallel to each other on the peripheral side The inner part 3 of the universal joint has three spherical outer parts which are arranged evenly distributed on the peripheral side and each protrudes radially into one of the recesses 5 of the outer part 2 of the universal joint. Pin 7 of profile 8 .

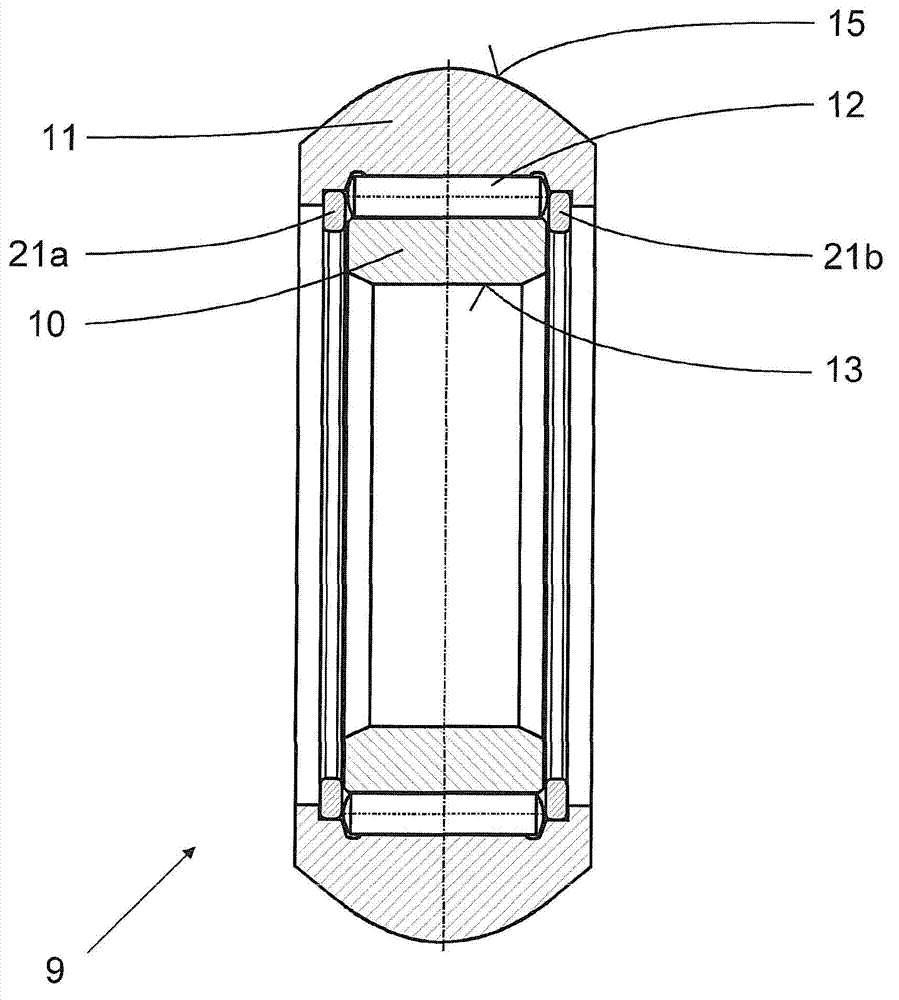

[0025] On each pin 7 of the universal joint inner part 3 there are arranged figure 2 shown separately in and in figure 1The three-pin roller 9 shown in an enlarged cross-sectional view has an inner roller ring 10 , an outer roller ring 11 and a plurality of cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com