A method of manufacturing a printed circuit board and a printed circuit board structure

A technology for printed circuit boards and manufacturing methods, which is applied in the directions of printed circuit components, electrical connection formation of printed components, and electrical connection of printed components, etc., can solve problems such as impedance discontinuity, and achieve the effect of improving quality and maintaining integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings. However, this embodiment mode can be an application of various inventive concepts, and can be embodied in various specific ranges. The specific embodiments are for illustrative purposes only, and the embodiments do not limit the scope of the disclosure.

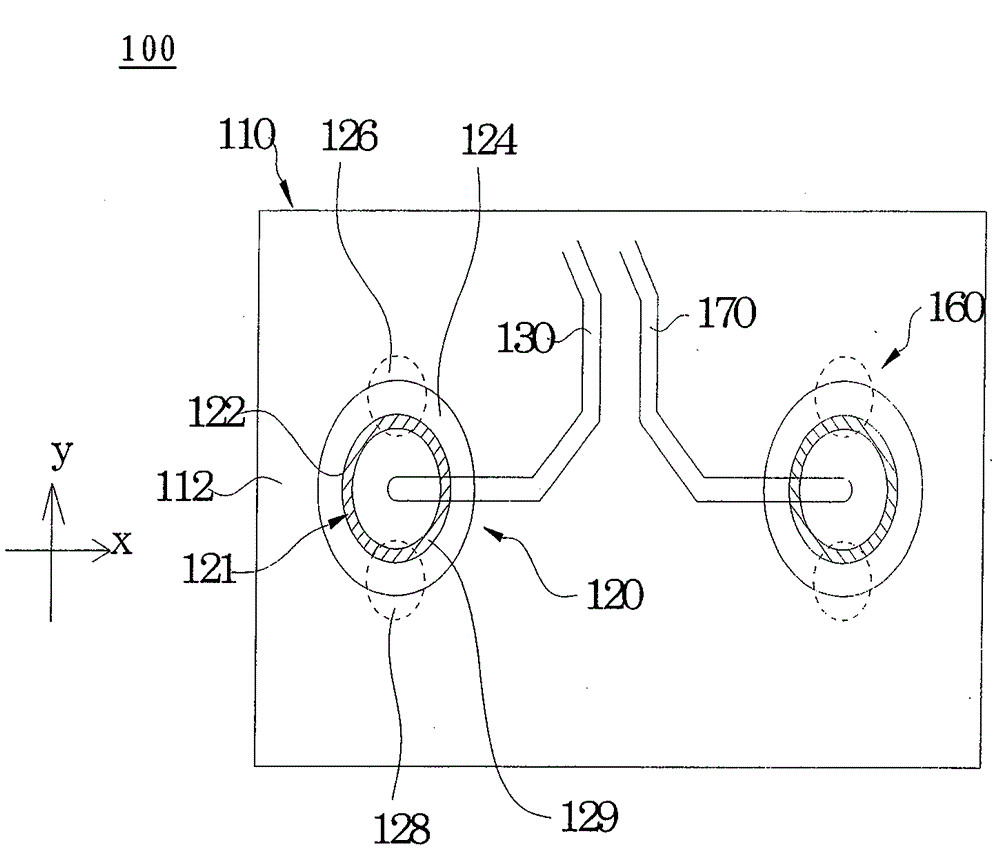

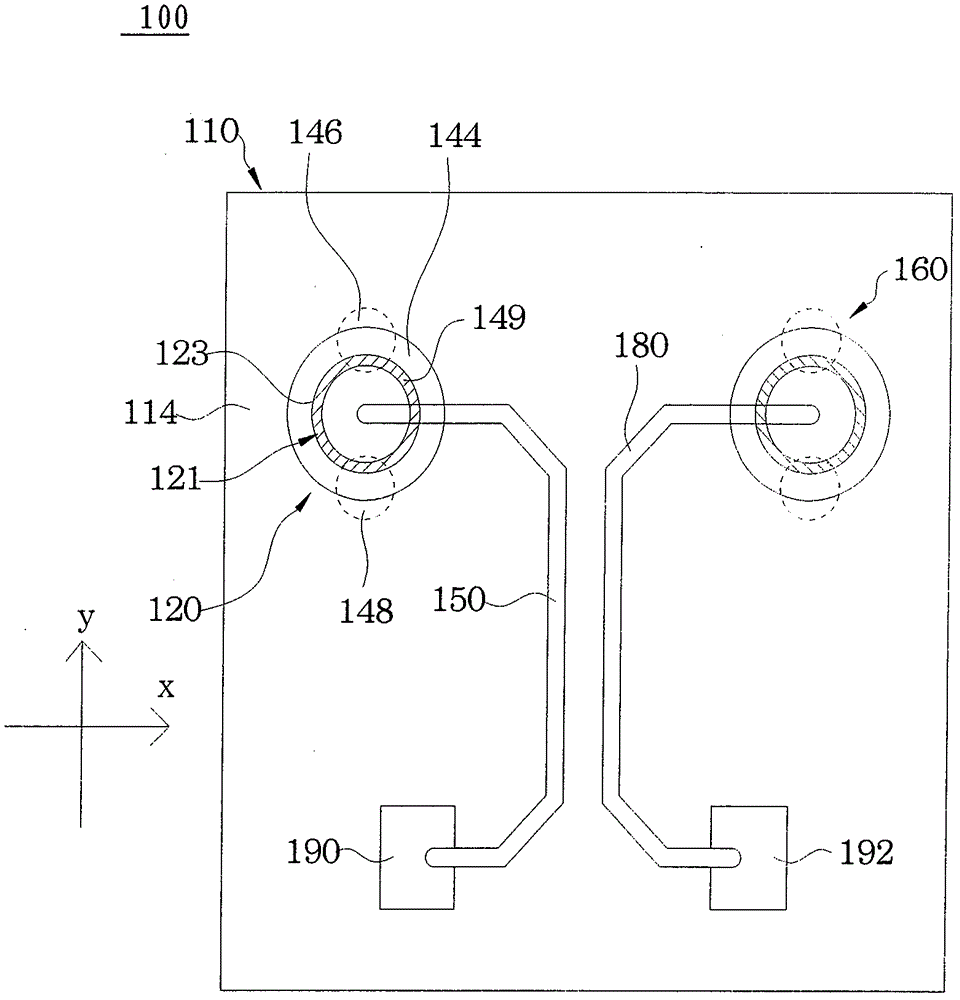

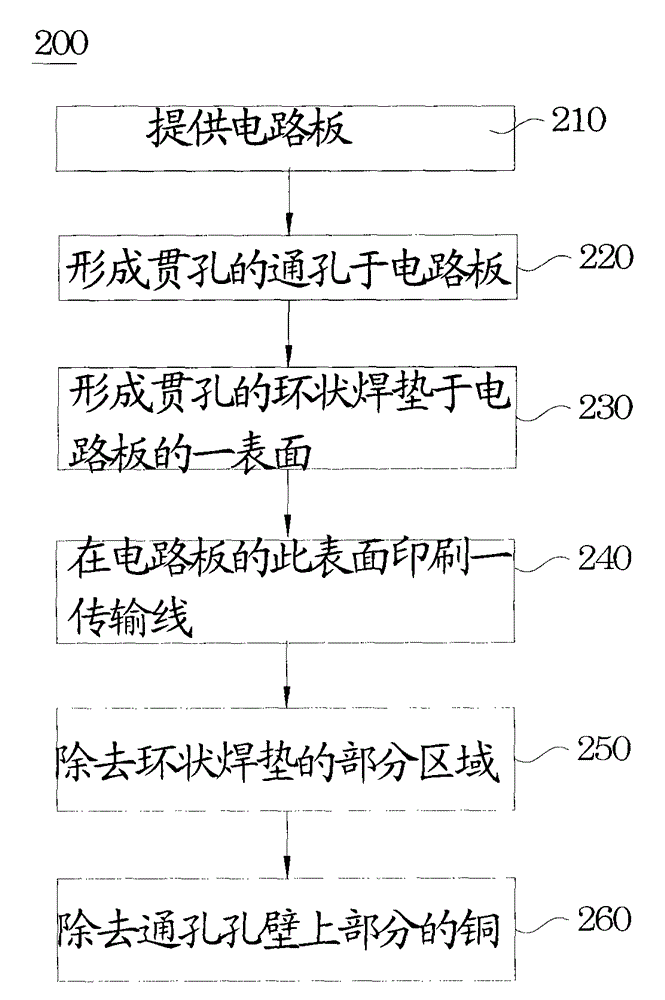

[0037] Generally, a through hole is composed of a ring-shaped pad on the outer layer and a hole wall perpendicular to the ring-shaped pad. When a pair of differential signals passes through the vias and is transferred from the upper layer to the lower layer, the width of the signal line will undergo multiple changes. For example, the line width of the transmission line is 5 mils. When the high-speed signal passes through the ring pad on the upper layer, the line width becomes 40 mils, and when passing through the hole wall, the line width becomes 24 mils. When the ring pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com