Multichip typesetting substrate and manufacturing method thereof

A manufacturing method and substrate technology, which are applied in the structural connection of printed circuits, printed circuit components, and electrical components to assemble printed circuits, etc., can solve the problem that the thickness of the step part is difficult to ensure, the accuracy is difficult to control, and the qualified printed circuit board sheet 502' Can't wait for the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

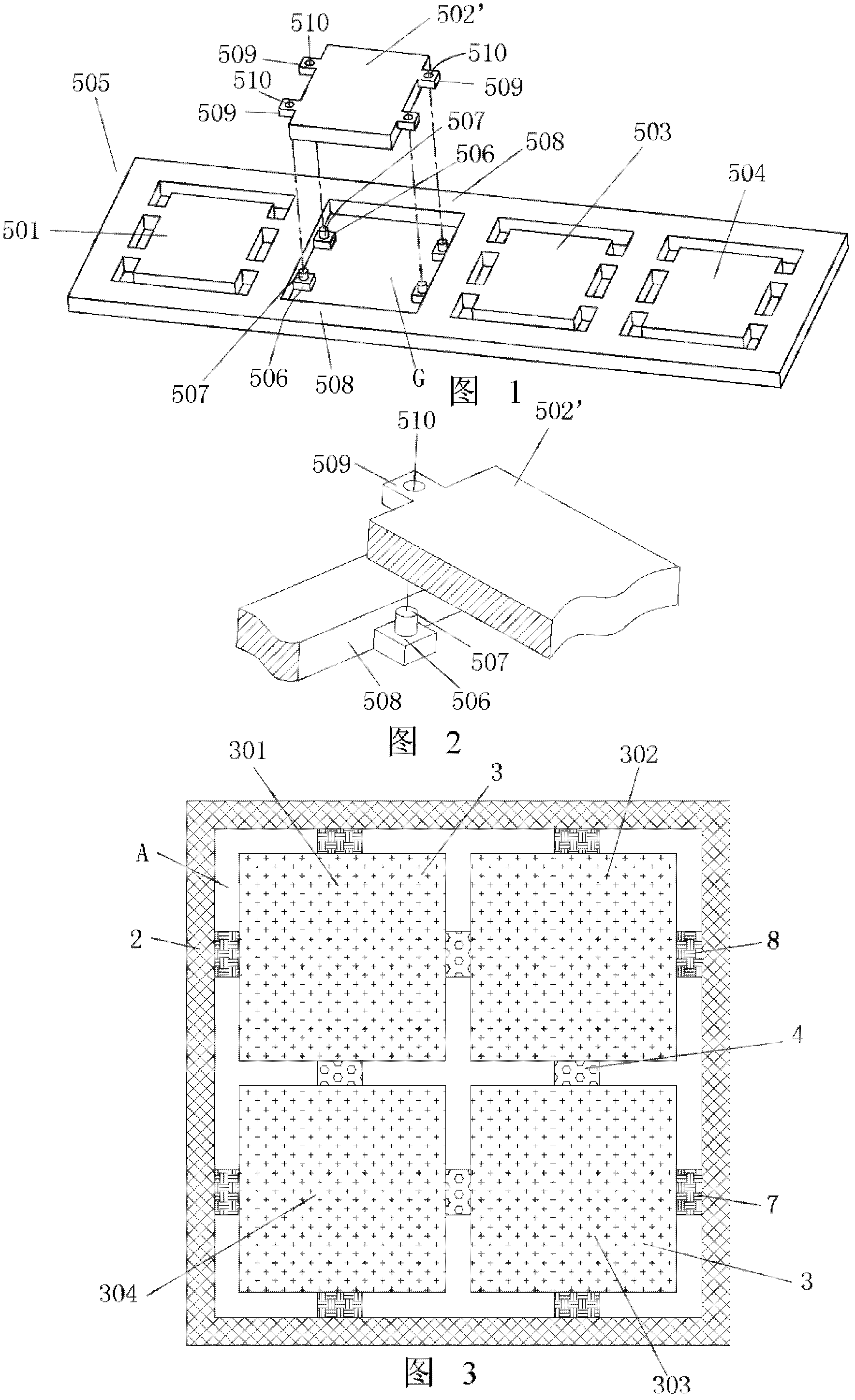

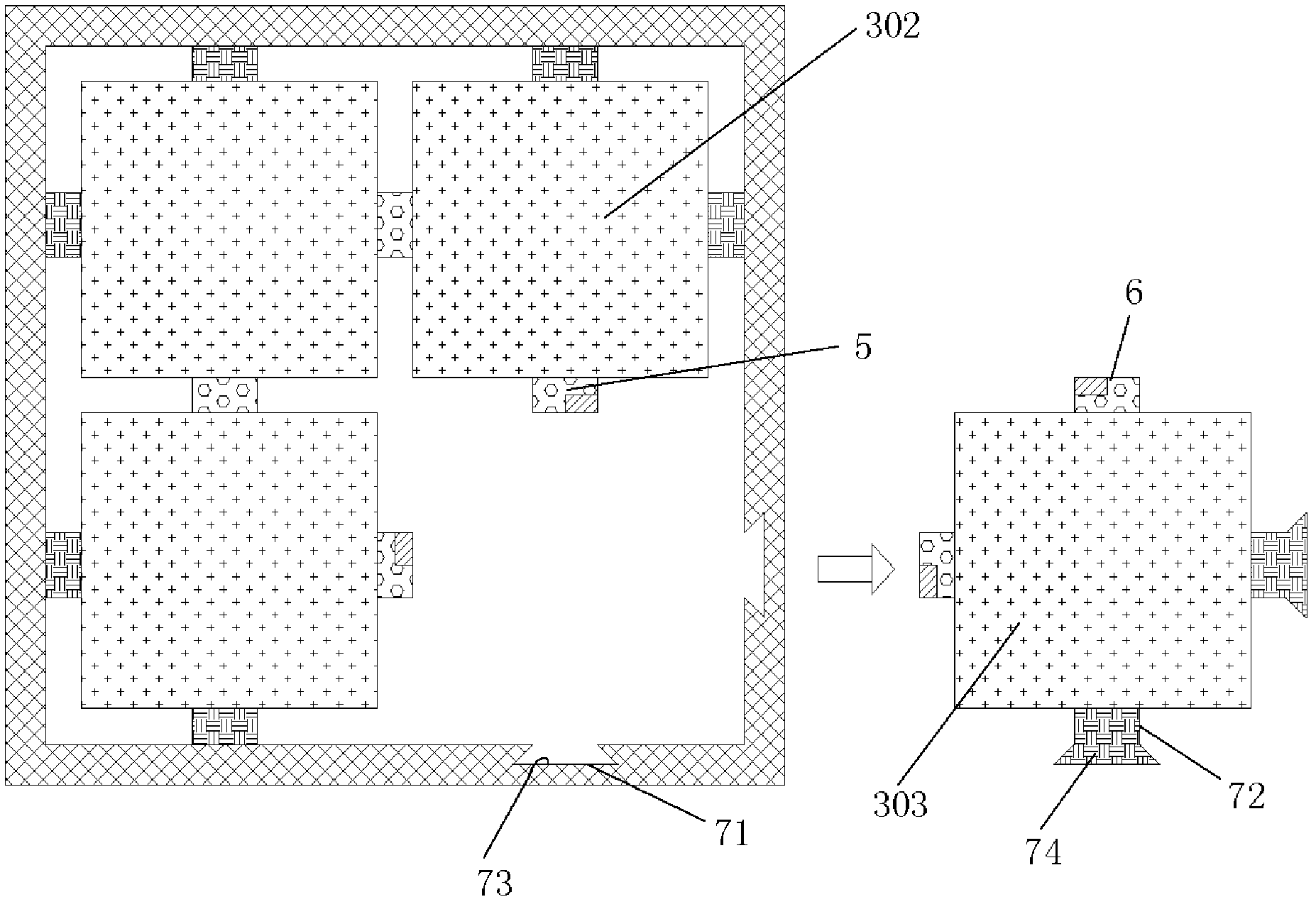

[0105] Such as image 3 As shown, it is a structural schematic diagram of a multi-piece typesetting substrate of the present invention, which includes a frame 2 and a plurality of sub-substrates 3, wherein, between the frame 2 and the sub-substrates 3, and between the sub-substrates 3 and the sub-substrates 3 are connected by a plurality of connection mechanisms 8 , the plurality of connection mechanisms 8 include at least one mechanical position-limiting connection mechanism 4 for limiting the displacement of the sub-substrate in two directions in the direction perpendicular to the frame surface or the surface of other sub-substrates, where the plurality of connections The mechanism 8 may also comprise at least one movement limiting mechanism 7 . An accommodating space A for accommodating the sub-substrate 3 is provided in the central part of the frame 2, here four substantially square sub-substrates 301, 302, 303, 304 are arranged, and each square sub-substrate is provided w...

Embodiment 2

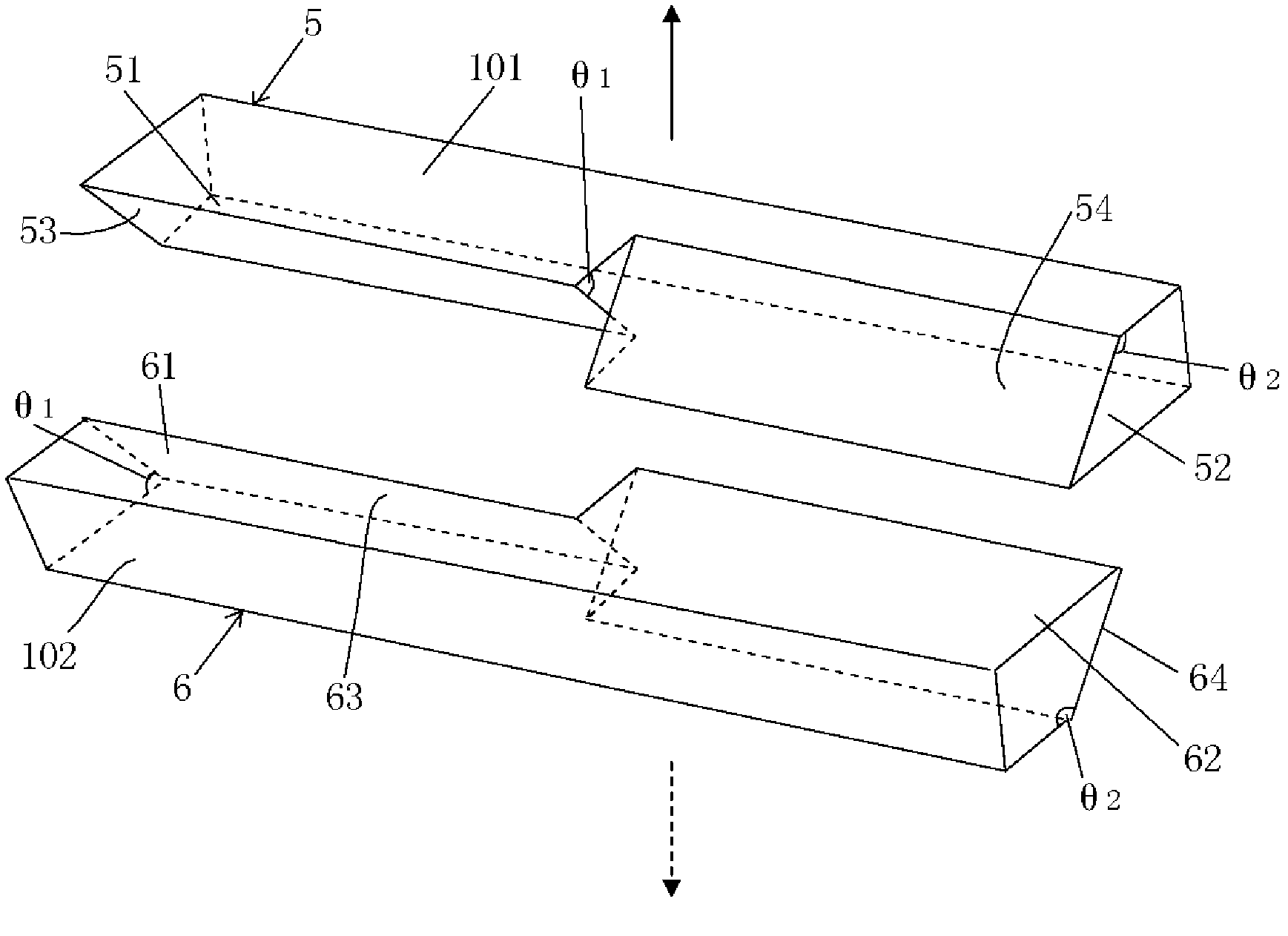

[0118] This embodiment is similar to Embodiment 1, and the same reference numerals are attached to the same structures as those of the multi-piece typesetting substrate in Embodiment 1, so the description of this part is omitted. The difference between this embodiment and embodiment 1 is: as Figure 8 As shown, after the first connecting mechanism 5 and the second connecting mechanism 6 cooperate with each other, a first notch 55 is also provided between the third connecting part 51 and the fourth connecting part 52, and the fifth connecting part 61 and the sixth connecting part A second notch 65 is provided between 62 at a position corresponding to the first notch 55 . The installation and operation of the first connecting mechanism 5 and the second connecting mechanism 6 are facilitated.

[0119] The formation of the first notch 55 here is naturally formed during the cutting process when the inclined surface 54 and the inclined surface 63 are processed. Likewise, the forma...

Embodiment 3

[0121] This embodiment is similar to Embodiment 1, and the same reference numerals are attached to the same structures as those of the multi-piece typesetting substrate in Embodiment 1, so the description of this part is omitted. The difference between this embodiment and embodiment 1 is: as Figure 9 As shown, the fifth connecting portion 61 and the sixth connecting portion 62 are multiple and interlaced with each other, and the third connecting portion 51 and the fourth connecting portion 52 that cooperate with them are correspondingly multiple, and mutually Staggered settings (figure omitted). Such as Figure 9A As shown, two fifth connecting parts 61 are arranged on the second connecting mechanism 6, and a sixth connecting part 62 is arranged in the middle. Correspondingly, two fifth connecting parts 61 are arranged on the first connecting mechanism 5. Three connecting parts 51 are provided with a fourth connecting part 52 (not shown) among them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com