LED packaging structure utilizing distant fluorescent powder layer and manufacturing method of LED packaging structure

A technology of LED packaging and phosphor layer, which is applied in the field of LED packaging structure and its manufacture, can solve the problems of disturbing chip light, uneven thickness, damage, etc., and achieve the effects of mass production, cost saving and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

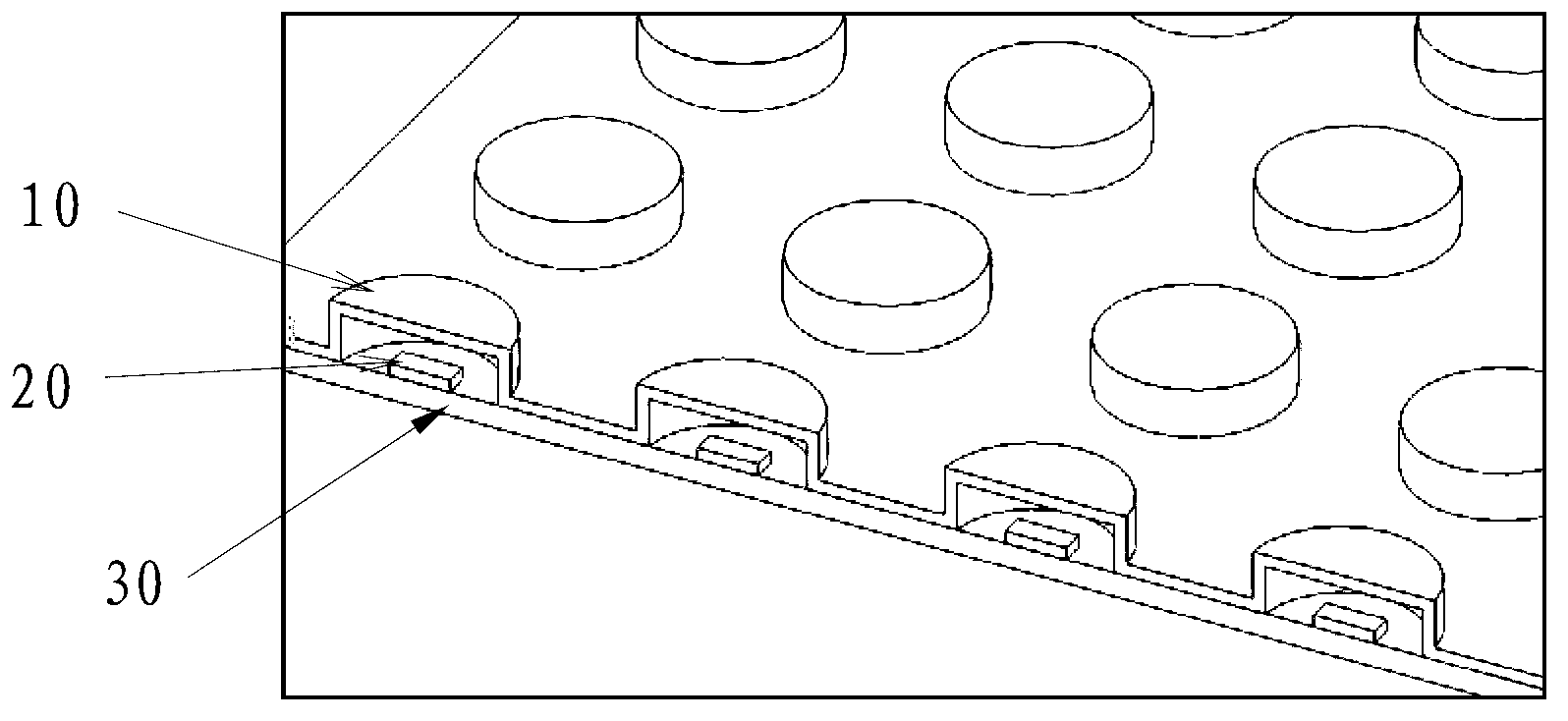

[0060] refer to Figure 1-3 , an LED packaging structure in this embodiment, comprising a substrate 30, an LED chip 20 and a phosphor layer 10, the LED chip 20 is fixed on the substrate 30, the phosphor layer 10 is a cover-like structure with a concave cavity, and the fluorescent The powder layer is bonded on the substrate, the phosphor layer and the substrate form a closed cavity, the LED chip is covered in a concave cavity, the volume of the concave cavity is larger than the volume of the LED chip, and the phosphor layer The space between the LED chip and the LED chip is a vacuum.

[0061] The shape of the concave cavity is cylindrical.

[0062] The preparation method of the above-mentioned fluorescent powder layer comprises the following steps: using a male mold and a female mold whose shapes cooperate with each other to prepare, the female mold is provided with at least one concave cavity, and the male mold is provided with a cavity that is compatible with the concave cav...

Embodiment 2

[0080] refer to Figure 7-9 In this embodiment, an LED packaging structure includes a substrate, an LED chip and a phosphor layer, the LED chip is fixed on the substrate, the phosphor layer is a cover-like structure with a concave cavity, and the phosphor layer is bonded to the substrate , the phosphor layer and the substrate form a closed cavity, the LED chip is covered in a concave cavity, the volume of the concave cavity is larger than the volume of the LED chip, and the gap between the phosphor layer and the LED chip The space between is vacuum.

[0081] The shape of the concave cavity is hemispherical.

[0082] The preparation method of the above-mentioned fluorescent powder layer comprises the following steps: using a male mold and a female mold whose shapes cooperate with each other to prepare, the female mold is provided with at least one concave cavity, and the male mold is provided with a cavity that is compatible with the concave cavity. The convex structure match...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com