Water-proof anti-corrosion electric power flexible cable

A flexible cable and anti-corrosion technology, which is applied in the direction of power cables with shielding layer/conductive layer, organic insulators, rubber insulators, etc., can solve problems such as inability to meet application requirements and shortages, achieve excellent waterproof and anti-corrosion performance, and improve use Effects of longevity, excellent weather resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

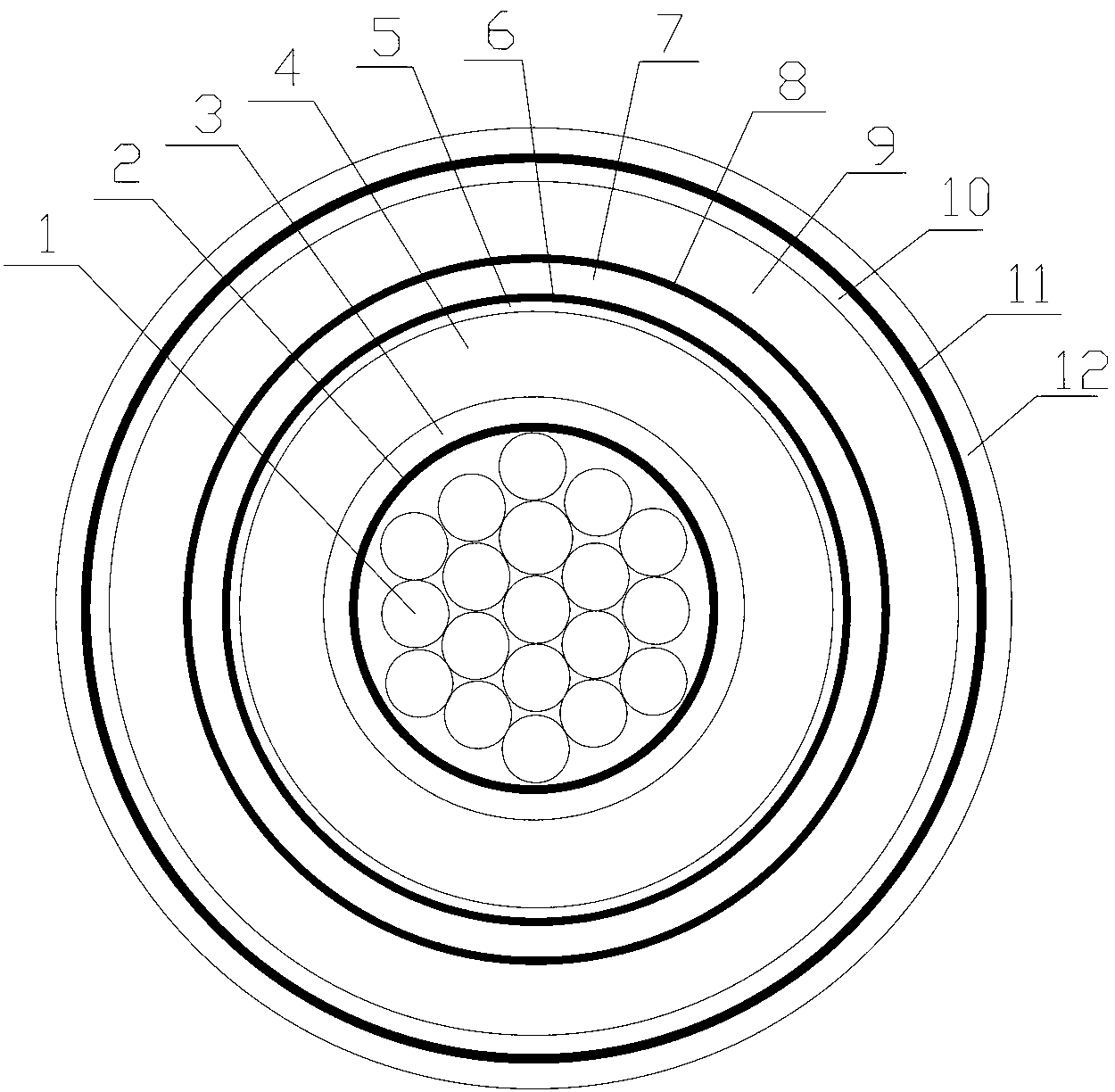

[0019] Such as figure 1 as shown, figure 1 It is a schematic cross-sectional structure diagram of a waterproof and anti-corrosion power flexible cable proposed by the present invention.

[0020] refer to figure 1 , a waterproof and anti-corrosion power flexible cable proposed by the present invention, comprising a conductor 1, and wrapping a conductor shielding layer 3, a rubber insulating layer 4, an insulating shielding layer 5, and a first braided shielding layer in sequence from the inside to the outside of the conductor 1 7. The inner sheath 9, the second braided shielding layer 10, the water-proof layer 11 and the outer sheath 12, wherein the outer sheath layer is made of chlorosulfonated polyethylene rubber, and the chlorosulfonated polyethylene rubber is made of the following The raw material compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com