Precast concrete member production quality detection system

A technology of prefabricated concrete and production quality, which is applied in the direction of computer parts, instruments, and collaborative operation devices, etc., can solve the problems of weakening the monitoring of production products, falsification of production quality, loss of form paper, etc., to increase portability and reliability. Reusability, increased efficiency, and cost-reduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

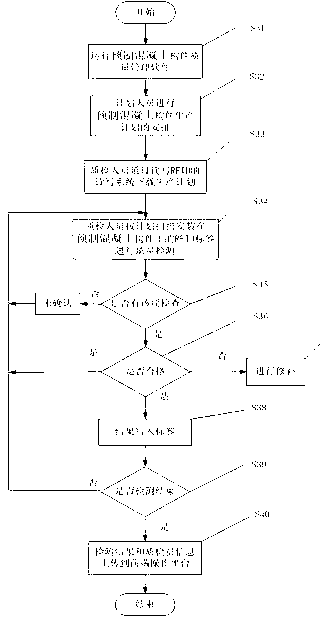

[0014] see figure 1 , the precast concrete component production quality inspection system consists of an RFID tag (113) installed on the precast concrete component through a UHF RFID reading and writing system (112), and a front-end operating platform computer (111) The background service system (114) is connected with the central database (115); the front-end operation platform computer (111) is used to generate the production quality inspection procedures and inspection items of precast concrete components, and the reading and writing system (112) for reading and writing UHF RFID ) Scan the RFID tags installed on the precast concrete components and record the quality inspection results of the precast concrete components.

Embodiment 2

[0016] This embodiment is basically the same as Embodiment 1, and the special feature is that, in addition to generating detection procedures and detection items, the front desk operation platform computer (111) will receive and read the UHF RFID reading and writing system (112) through the network The transmitted test results and quality inspector information; the read-write system (112) of the UHF RFID is a CSL-type UHF handheld terminal, which receives the detection procedures and In addition to the detection items, the detection results are also written into the RFID tags (113) installed on the prefabricated concrete components; the read-write UHF RFID reading and writing system (112) will be installed on the TID of the RFID on the prefabricated concrete components , test results and quality inspector information are transmitted to the front-end operating platform computer (111), and then the front-end operating platform computer (111) transmits the above information to the...

Embodiment 3

[0018] figure 2 The production quality inspection system of the prefabricated concrete component is shown. They are formed by connecting the front-end operating platform computer (21) and the CSL ultra-high frequency handheld terminal (22) produced by Hong Kong Xinghua Technology through the network, and the CSL ultra-high frequency handheld terminal (22) is obtained through ISO / IEC 18000 protocol to read and write to RFID tags (23) mounted on precast concrete elements. The front-end operation platform first runs the "precast concrete component quality management software" (211) through the production planner to arrange the production plan of precast concrete components, and the quality inspection management personnel perform production quality inspection procedures and inspection items according to the type of precast concrete components in the production plan Then the software transmits the information to the central database (25) of the background service system (24) thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com