Color film substrate and manufacturing method and display device thereof

A technology of a color filter substrate and a manufacturing method, applied in the display field, can solve the problems of high cost and size limitation of auxiliary spacers, and achieve the effect of avoiding high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

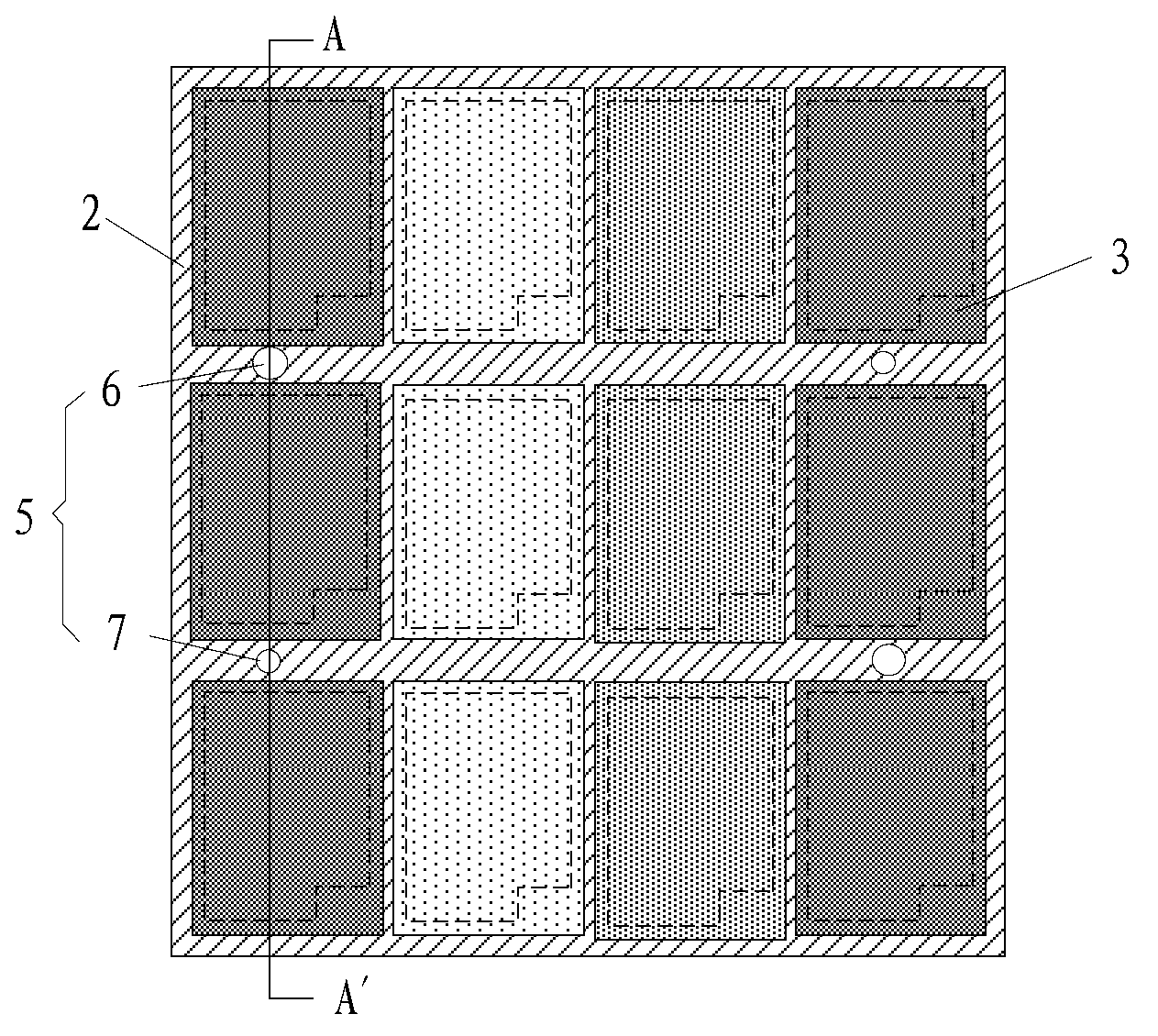

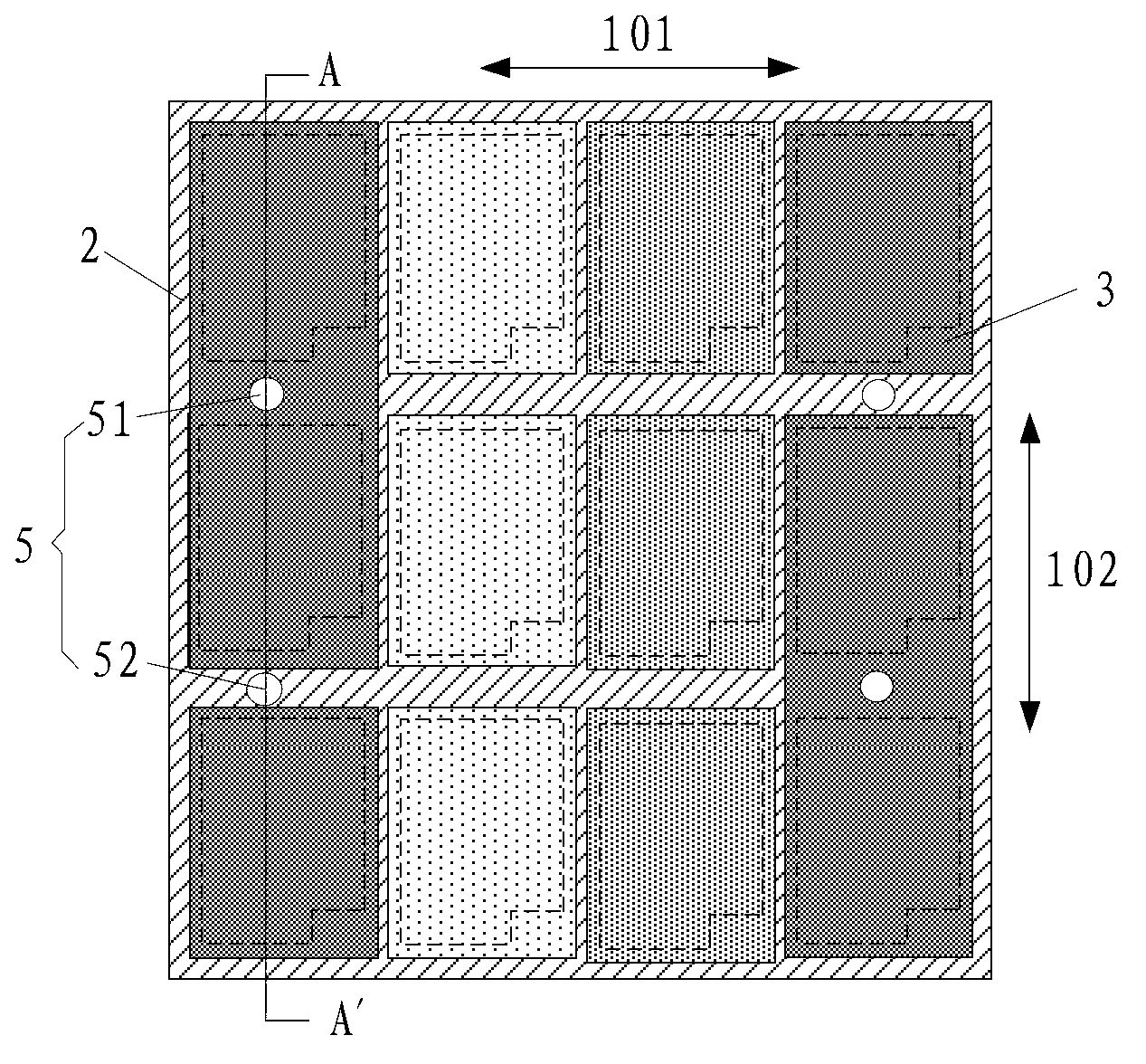

[0034] An embodiment of the present invention provides a color filter substrate, such as image 3 , Figure 4 As shown, it includes: a transparent substrate 1, a black matrix film layer 2 and a color film layer 3 arranged on the transparent substrate 1, and a spacer film layer 5 arranged above the black matrix film layer 2; wherein, The spacer film layer 5 includes: a first spacer 51 and a second spacer 52; the color film layer 3 is located below the spacer film layer 5 and covers the first spacer 51 and does not cover the area where the second spacer 52 is located.

[0035] It should be noted that the "upper" and "lower" in the embodiments of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com