Battery cycle performance accelerating and evaluating method

A battery cycle, battery technology, applied in the direction of secondary battery repair/maintenance, measurement of electricity, measurement of electrical variables, etc., can solve the problems of resource, energy waste, and increase the cost of battery cycle performance evaluation, so as to reduce production costs and increase market. Application prospect, effect of significant production practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

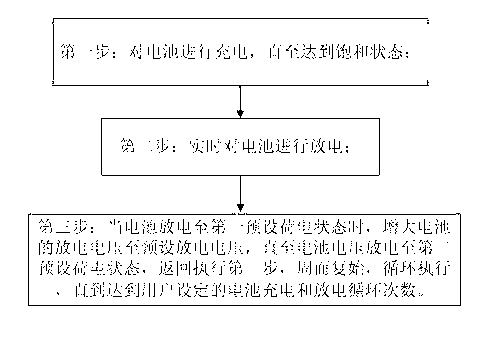

Method used

Image

Examples

Embodiment 1

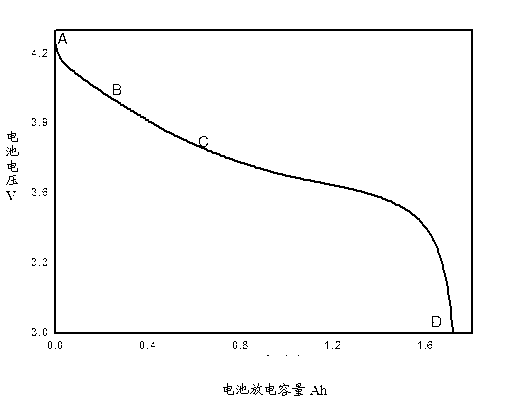

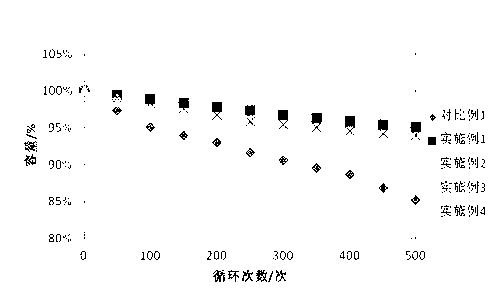

[0045]The preset discharge voltage is 4.0V. The charging system remains unchanged, so that lithium ions can be inserted into the negative electrode as saturated as possible, the discharge voltage is set to 4.0V, keep shallow charging and shallow discharge for 49 times, fully discharge to 3.0V at the 50th time, 50 times a cycle, cycle 10 cycle at 25°C for 500 cycles; cycle 8 for 400 cycles at 45°C. The specific charging and discharging cycle system is shown in Table 2.

[0046] Table 2: Cycling test conditions for Example 1.

[0047]

[0048]

[0049] A charging and discharging cycle is 1 hour and 15 minutes, and it takes 29 days to complete according to the requirement of 500 cycles.

Embodiment 2

[0051] The preset discharge voltage is 3.8V (below the voltage platform). The method is the same as that of Example 1, the discharge voltage of the limited shallow discharge and shallow charge is 3.8V, and the specific charge and discharge cycle system is shown in Table 3.

[0052] Table 3: Cycling test conditions for Example 2.

[0053]

[0054]

[0055] A charging and discharging cycle is 2 hours and 30 minutes, and it takes 1 month and 22 days to complete according to the requirement of 500 cycles.

Embodiment 3

[0057] The preset discharge voltage is 4.0V and the discharge current is 1C. Under the conditions of the method in Example 1, increase the discharge current to 1C, and discharge the lithium ions on the negative electrode to the positive electrode through the diaphragm, which will basically not damage the battery. Therefore, the discharge current can be increased, but the current should be smaller than that in the specification. Indicated maximum discharge current. For the experimental battery in the present invention, 1C is the maximum discharge current, therefore, this embodiment selects 1C as the discharge current. The specific charging and discharging cycle system is shown in Table 4.

[0058] Table 4: Cycling test conditions for Example 3.

[0059]

[0060]

[0061] A charging and discharging cycle is 1 hour, and it takes 21 days to complete according to the requirement of 500 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com