Micro spectrometer integrating planar variable-pitch grating and micro slit and manufacture method of micro spectrometer

A technology of variable grating pitch grating and miniature spectrometer, applied in the field of spectral analysis instruments, can solve the problems of unsatisfactory spectral resolution, poor aberration effect, difficult processing of curved components, etc., and achieves simple and compact structure, reduced aberration, easy The effect of encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

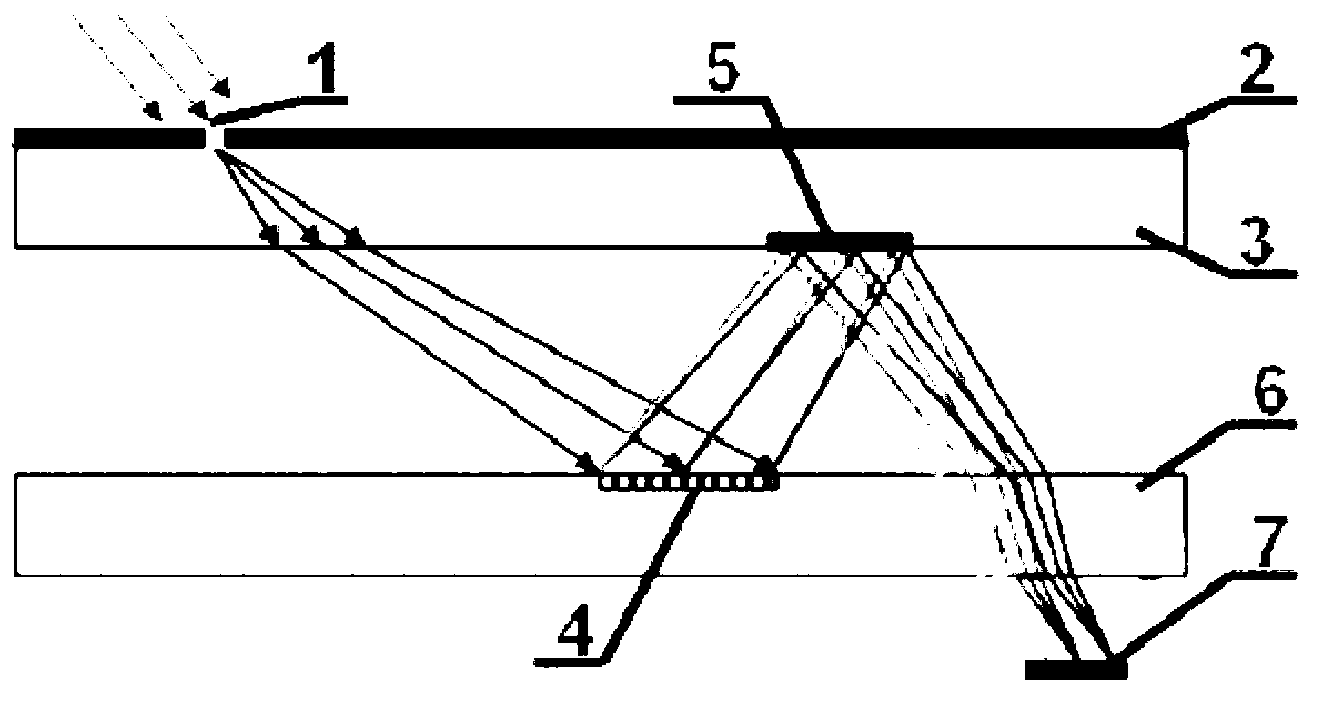

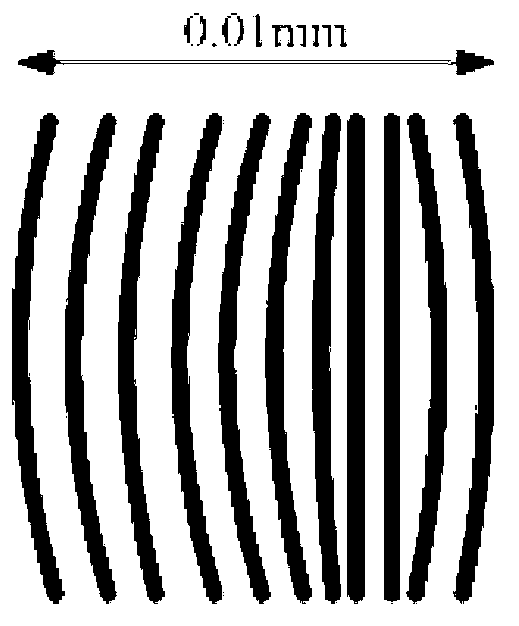

[0032] Such as figure 1 and figure 2As shown, a micro-spectrometer integrating planar variable pitch gratings and micro-slits provided by the embodiment of the present invention includes an array photodetector 7, an upper light-transmitting flat plate 3 and a lower light-transmitting flat plate 6, and the upper light-transmitting flat plate 3. The array photodetector 7 is arranged at the lower end of the lower light-transmitting plate 6 in parallel with the lower light-transmitting plate 6; the array photodetector 7 can be attached to the lower surface of the lower light-transmitting plate 6 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com