Precise detection device and detection method of principal axis cone hole accuracy

A technology of detection device and taper hole, applied in the direction of measurement device, measurement force, instrument, etc., can solve problems such as low detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

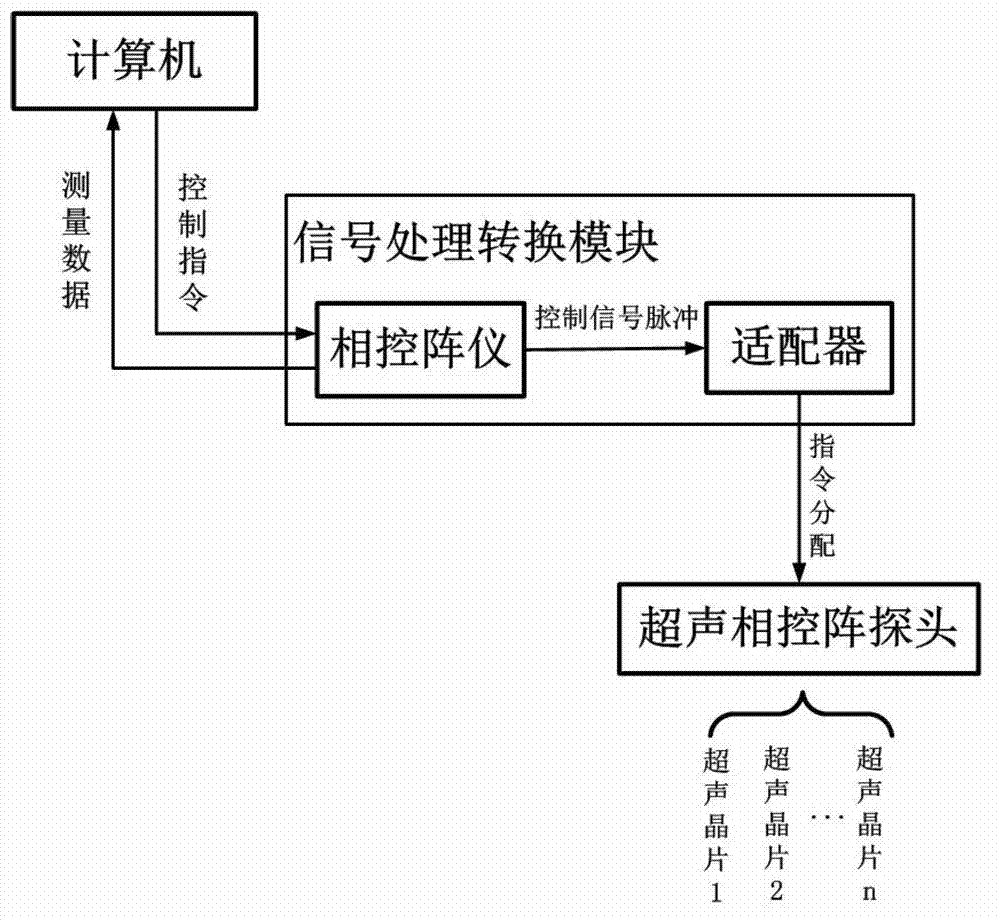

[0030] see figure 1 , the accurate detection device of main shaft taper hole accuracy of the present invention, comprises computer and the signal processing conversion module that is connected with computer, and wherein signal processing conversion module is connected with the taper gauge 2 with ultrasonic phased array probe 5; Signal processing conversion module comprises The phased array instrument and the adapter, the phased array instrument is connected to the computer through the data line, the control signal output terminal of the phased array instrument is connected to the adapter, and the command distribution port of the adapter is connected to the ultrasonic phase control on the tapered gauge 2 through an extension cable. array probe5.

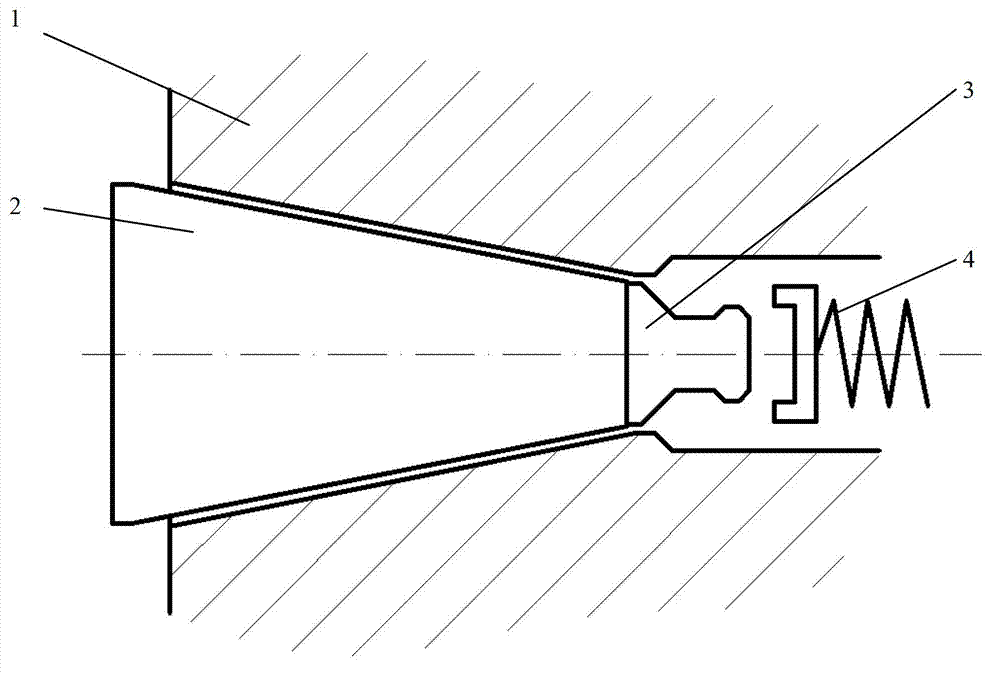

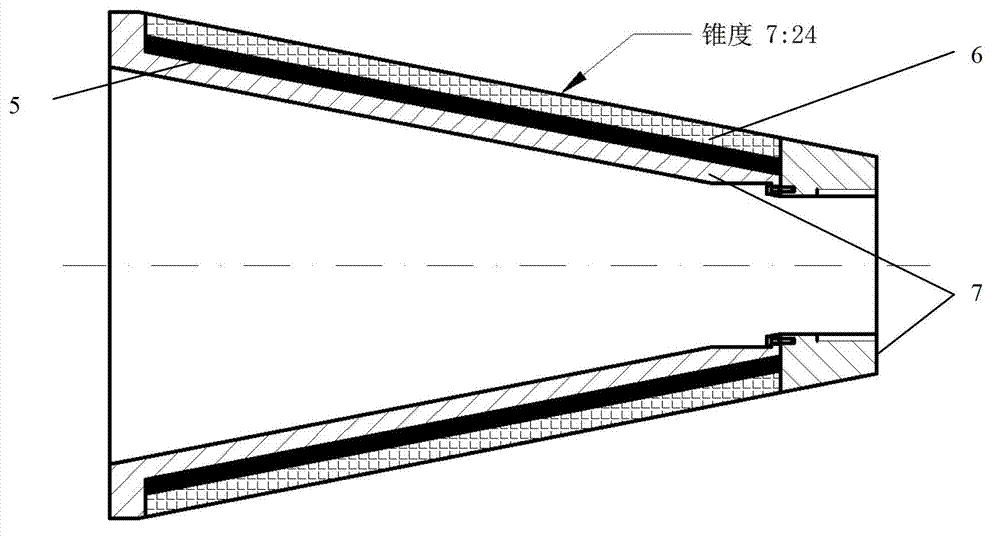

[0031] Such as figure 2 and image 3 , the tapered gauge 2 of the present invention is composed of an integrated wedge 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com