Method for measuring dynamic oil film pressure distribution of sliding bearing in real time

A sliding bearing and oil film pressure technology, which is applied in measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of not being able to obtain the accurate value of oil film pressure in real time and different oil films, and achieve low cost, good processing performance and chemical stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

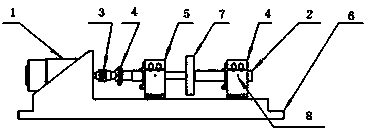

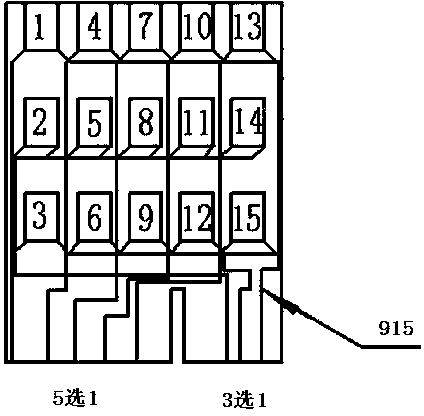

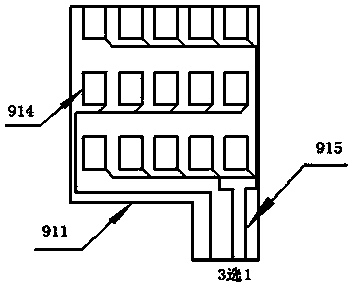

[0031] The patent of the present invention relates to a method for real-time measurement of the dynamic oil film pressure distribution of a sliding bearing, including (1) making at least one special sliding bearing; the special sliding bearing is equipped with a piezoelectric sensor array, and the piezoelectric sensor array is evenly distributed in the bearing. Converting the oil film pressure on the sliding bearing into an electrical signal and outputting the electrical signal; (2) Installing at least one of the special sliding bearings on a sliding bearing measurement platform; (3) Passing a signal conditioning acquisition circuit through the The piezoelectric sensor array is connected to the special sliding bearing, and is used to process and convert the weak electrical signal containing noise output by the piezoelectric sensor array into an identifiable effective signal, and obtain the oil film pressure distribution according to the effective signal. Wherein, the piezoelect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com