Asymmetric arc boundary layer pressure measuring bent frame

An asymmetric and arc-shaped technology, applied in the field of asymmetric arc-shaped boundary layer pressure measuring brackets, can solve the problems of reducing the measurement accuracy, the interference effect of the measurement results, and the unfavorable velocity and rapid change of flow field data fitting, etc. Achieve the effect of improving measurement accuracy, high practical value, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

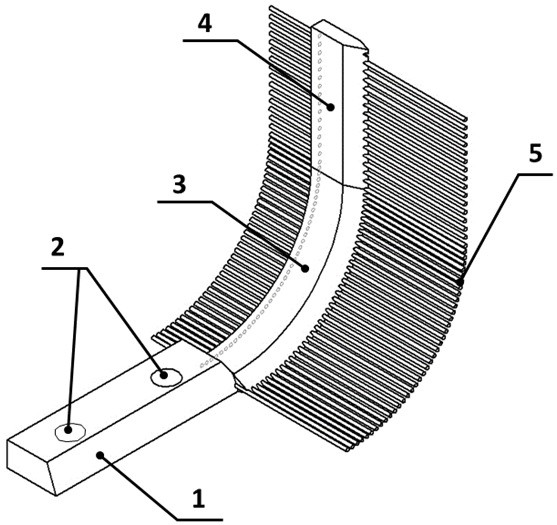

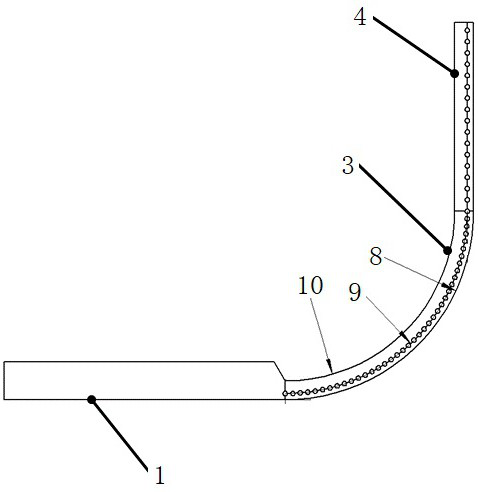

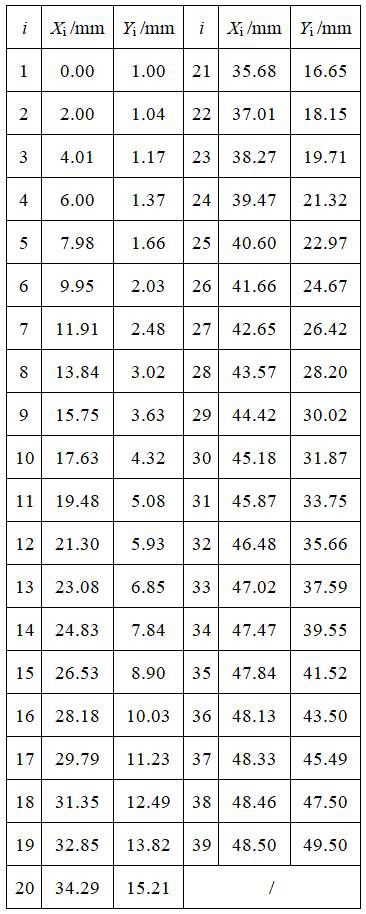

[0040] This embodiment provides an asymmetric circular arc-shaped boundary layer pressure measurement bend applied to a 0.6-meter transonic wind tunnel, with a height of 100 mm and a spanwise length of 50 mm, which can meet the boundary layer flow during sub-, transonic, and supersonic operation. Characteristic measurement requirements.

[0041] The structure of the asymmetric arc-shaped boundary layer pressure measuring bent frame in this embodiment is as follows figure 1 , figure 2 As shown, the whole set of bent brackets includes four main parts: the mounting base, the arc section bracket, the straight section bracket, and the pressure measuring probe.

[0042] Such as figure 1 As shown, the mounting seat is flat, with fixing holes provided on it, and its front end in the windward direction is chamfered. Preferably, the fixing holes are countersunk screw holes for installing countersunk screws. In this embodiment, the mounting seat is used to fix the pressure measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com