Impulse test system of hydraulic hose

A technology for hydraulic hose and pulse test, which is applied in the testing of fluid pressure actuation systems, fluid pressure actuation devices, mechanical equipment, etc. The effect of avoiding the use of the charge pump and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

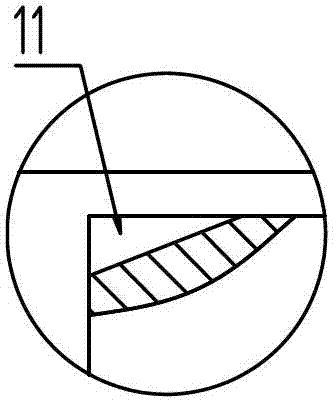

[0018] Embodiment 1, figure 1 and figure 2 A hydraulic hose impulse test system is presented, including hydraulic impulse loading system, temperature control system, tested hydraulic hose connection block I16, tested hydraulic hose connection block II19 and controller 23.

[0019] The hydraulic pulse loading system described above includes an oil source 24, a hydraulic control valve 7, an electro-hydraulic servo valve 6, a booster cylinder 12, an accumulator I5 and an accumulator II10; the oil source 24 includes a main oil tank 1, a hydraulic pump 2 , relief valve 3 and one-way valve I4; hydraulic pump 2 can discharge pressure oil to provide hydraulic energy for the system; one-way valve I4 is used to ensure that oil can only flow from hydraulic pump 2 to the system, but not reverse. The relief valve 3 is used to limit the maximum pressure of the oil source 24 .

[0020] The hydraulic pump 2 is a variable pump or a combination of quantitative pumps; the combination of quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com