Method of quickly identifying crankshaft position

A crankshaft position, crankshaft technology, applied in engine control, machine/engine, electrical control, etc., to achieve high efficiency, fast transformation, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

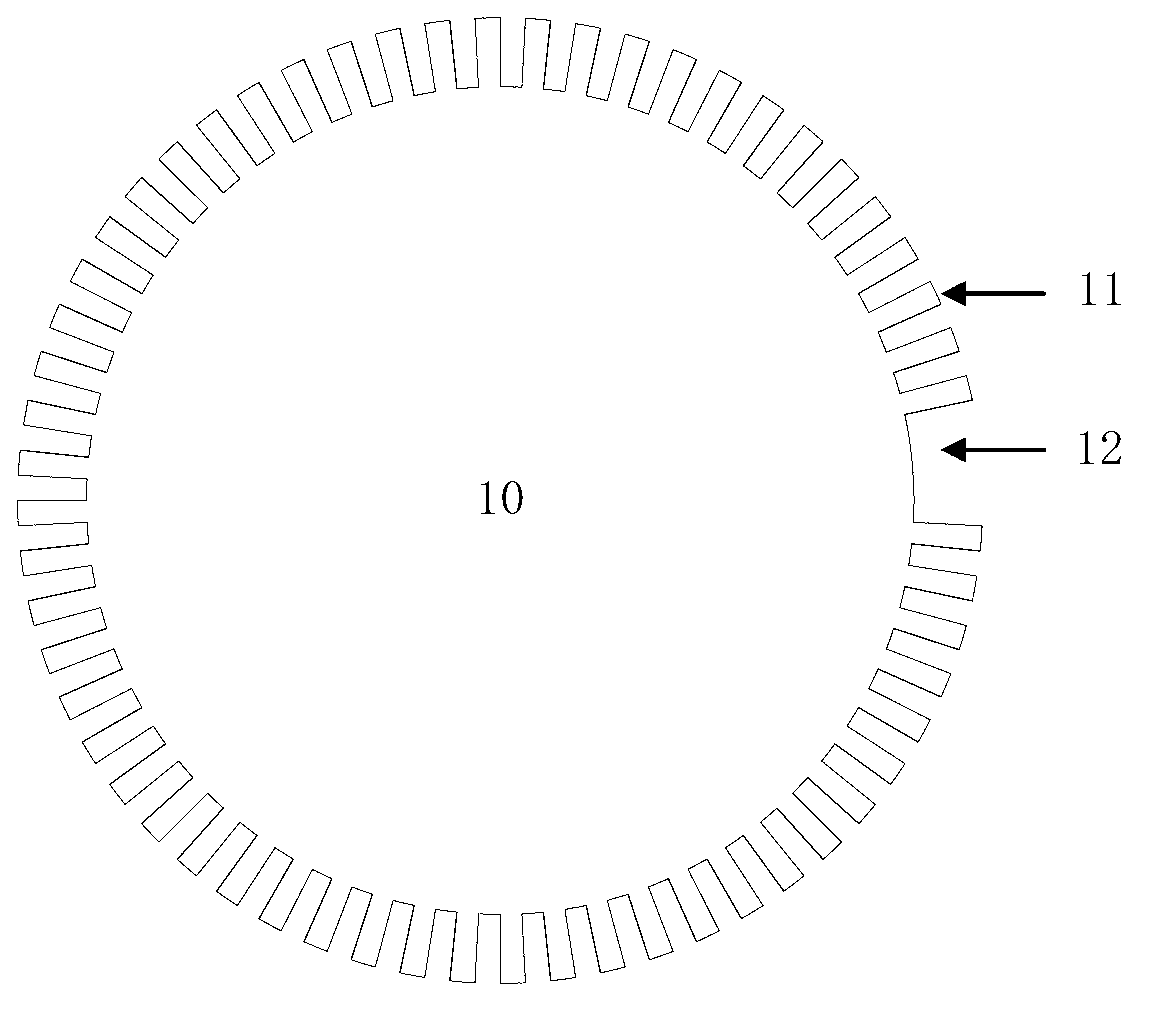

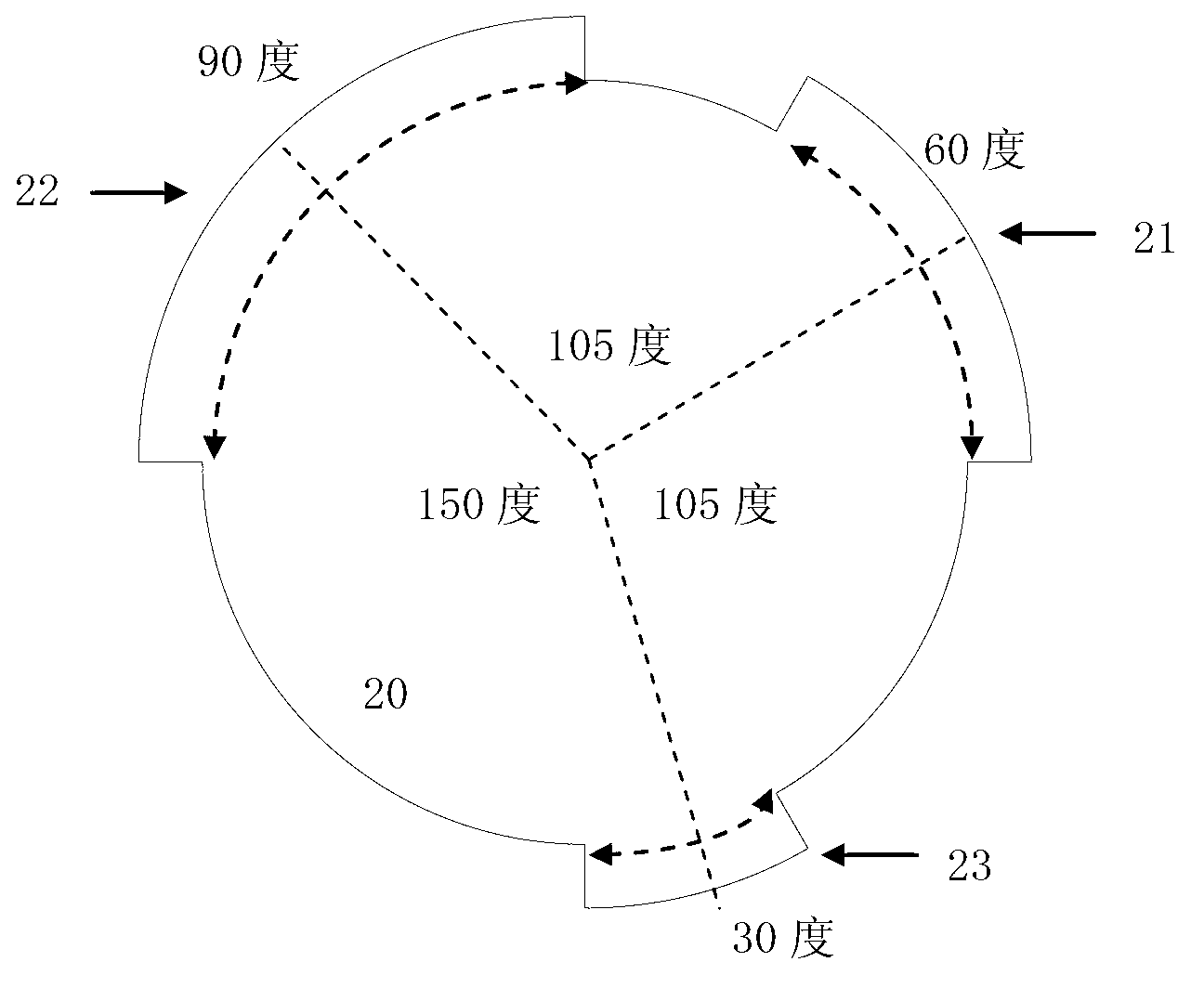

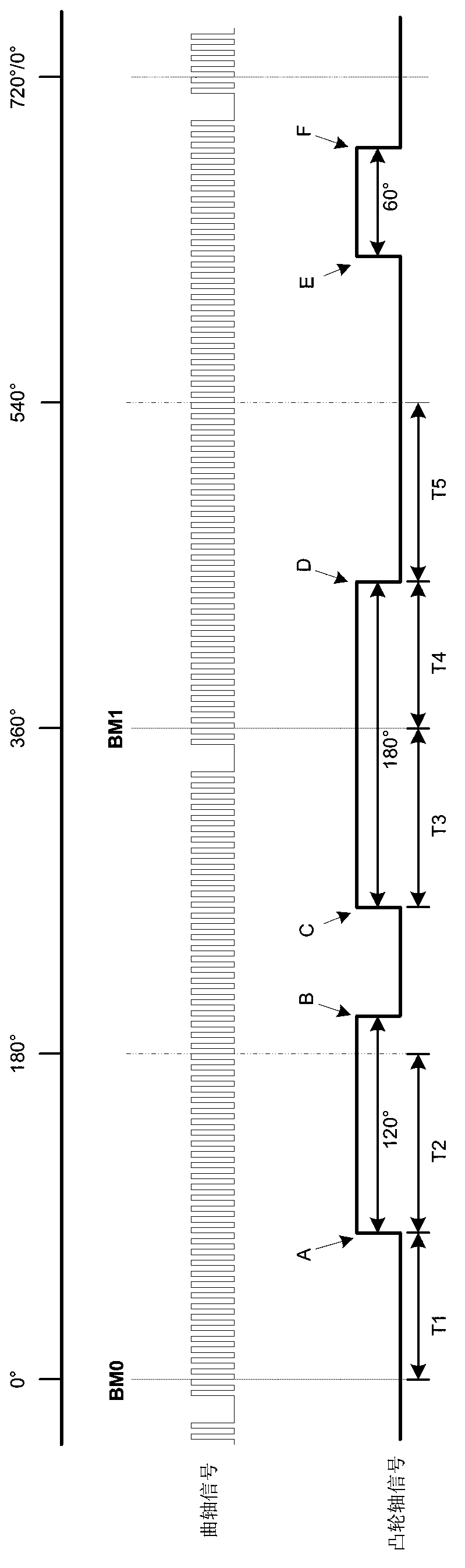

[0028] The applicable environment of this application is: a four-stroke engine, the crankshaft position sensor and the camshaft position sensor are Hall sensors. There are several normal teeth evenly distributed on the crankshaft signal wheel, and there is at least one missing tooth. The camshaft signal wheel has three lobes.

[0029] Typically, the engine builder installs the crankshaft signal wheel strictly to a parameter that specifies the angle at which the missing tooth position is from top dead center on the first cylinder. That is, when the engine is rotating, if the tooth-missing position is detected, it can be determined that the above-mentioned angle is the top dead center of the first cylinder (but because the crankshaft rotates twice in each working cycle of the engine, it is impossible to rely solely on this angle information to determine whether the top dead center is compression top dead center or exhaust top dead center)

[0030] see figure 1 , the crankshaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com