High-stiffness monolithic prestress assembly type foundation pit bracing inner-supporting system

A foundation pit support and support system technology, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems of low rigidity of buttresses or corner braces, and achieve small deformation of foundation pits, high overall stability, and predictable prestress tune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

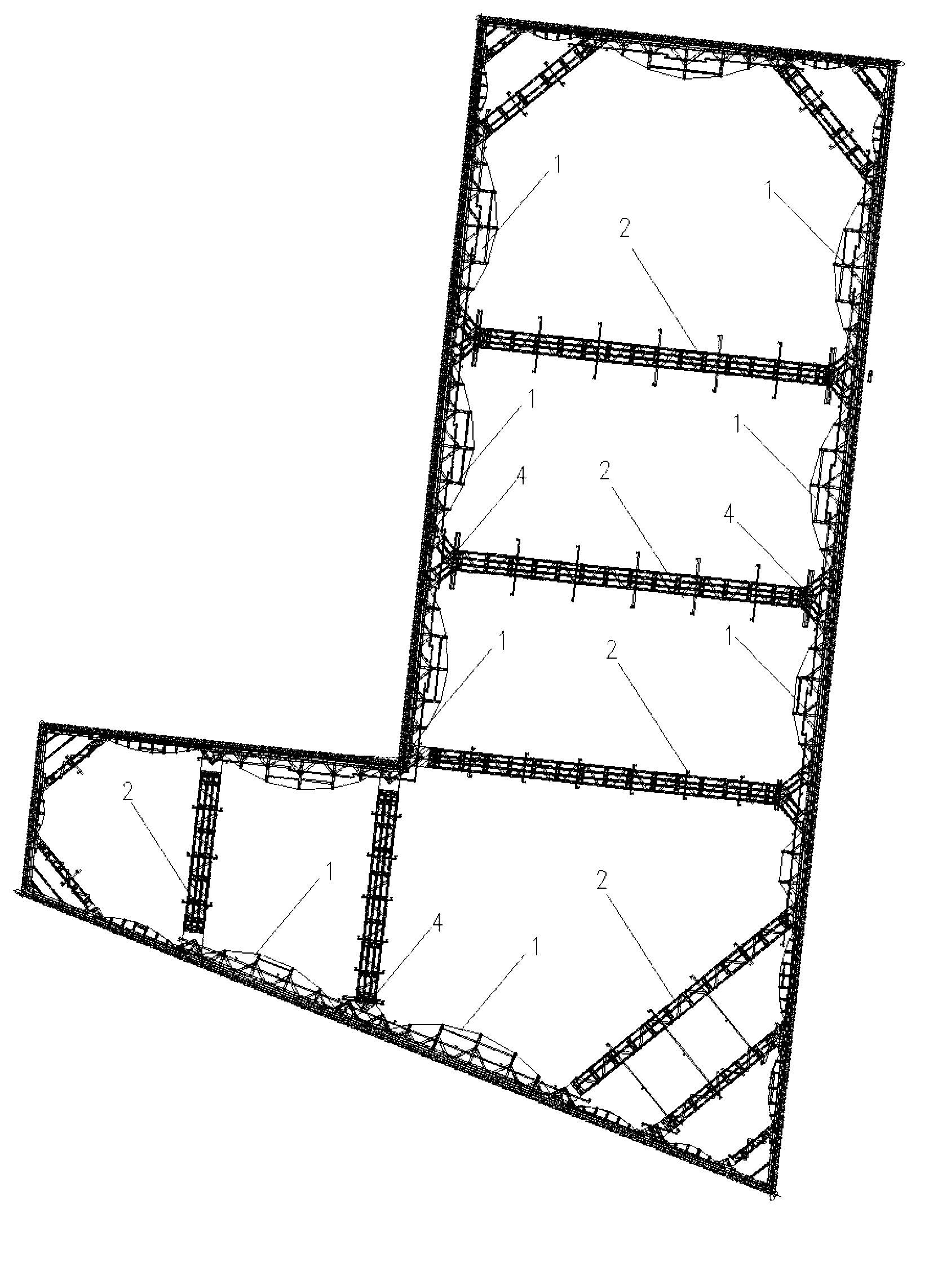

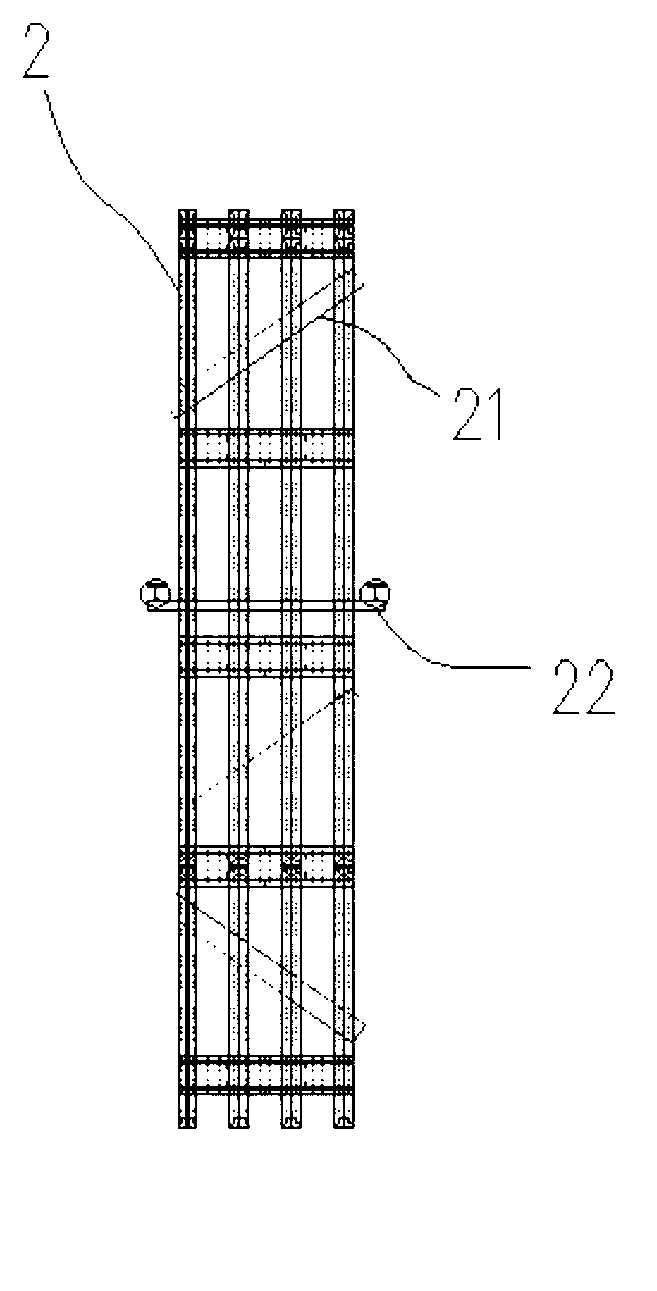

[0021] see figure 1 , the support structure in this embodiment is mainly composed of four parts: steel purlin 1, corner brace or counter brace 2, prestress loading device 3, steel purlin and corner brace or counter brace connection integral connection key 4, etc. .

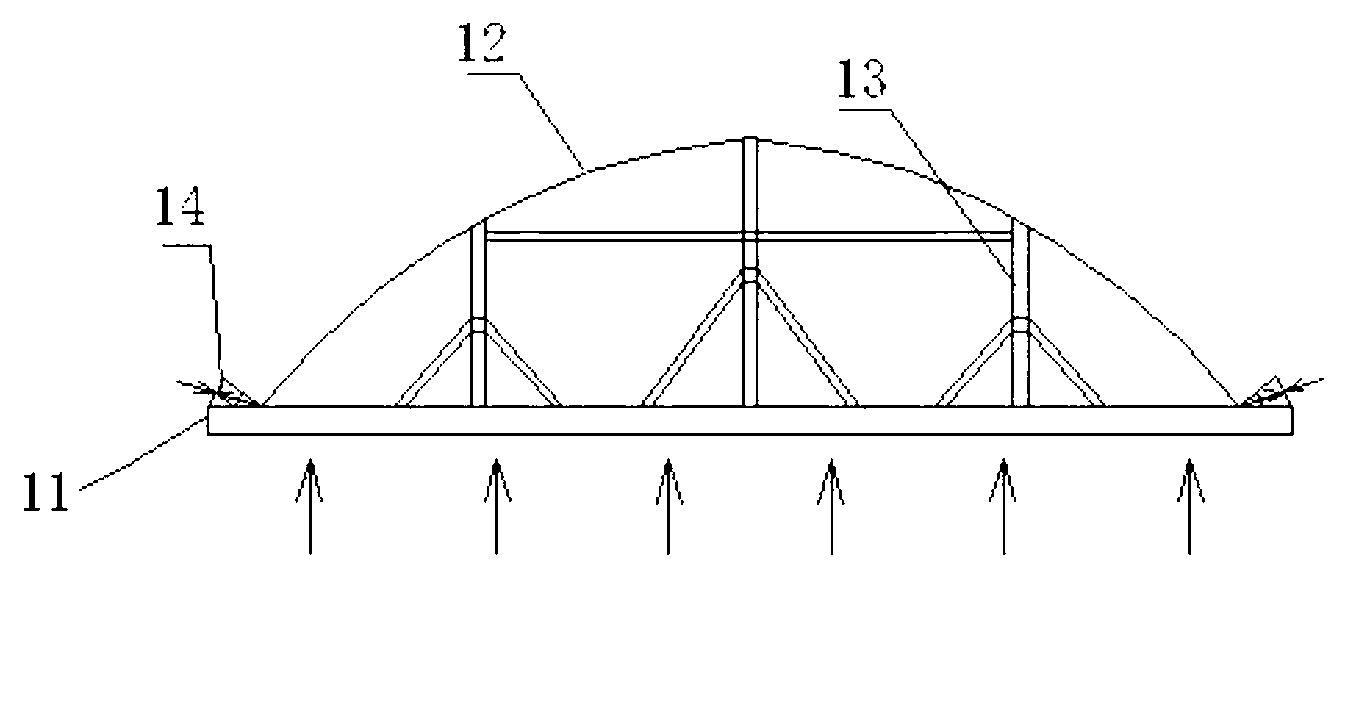

[0022] see figure 2 , Steel purlin structure, including a lower chord beam 11, steel strand 12, web bar 13,, special anchorage 14 components.

[0023] The web bar 13 is arranged on the string beam 11, the two ends of the steel strand 12 are connected to the two ends of the lower string beam 11, and the middle part of the steel strand 12 is supported by the web bar 13 in a fish-belly or arc shape. Assemble the section steel and steel strands into a purlin with a fish-belly struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com