Method for producing PPDI based polyurethane micropore elastomer

A technology of microcellular elastomer and polyurethane, which is applied in the field of preparation of polyurethane microcellular elastomer, can solve the problems of large dynamic fatigue deformation, low ball resilience, high compression set value, etc., and achieve the effect of overcoming large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

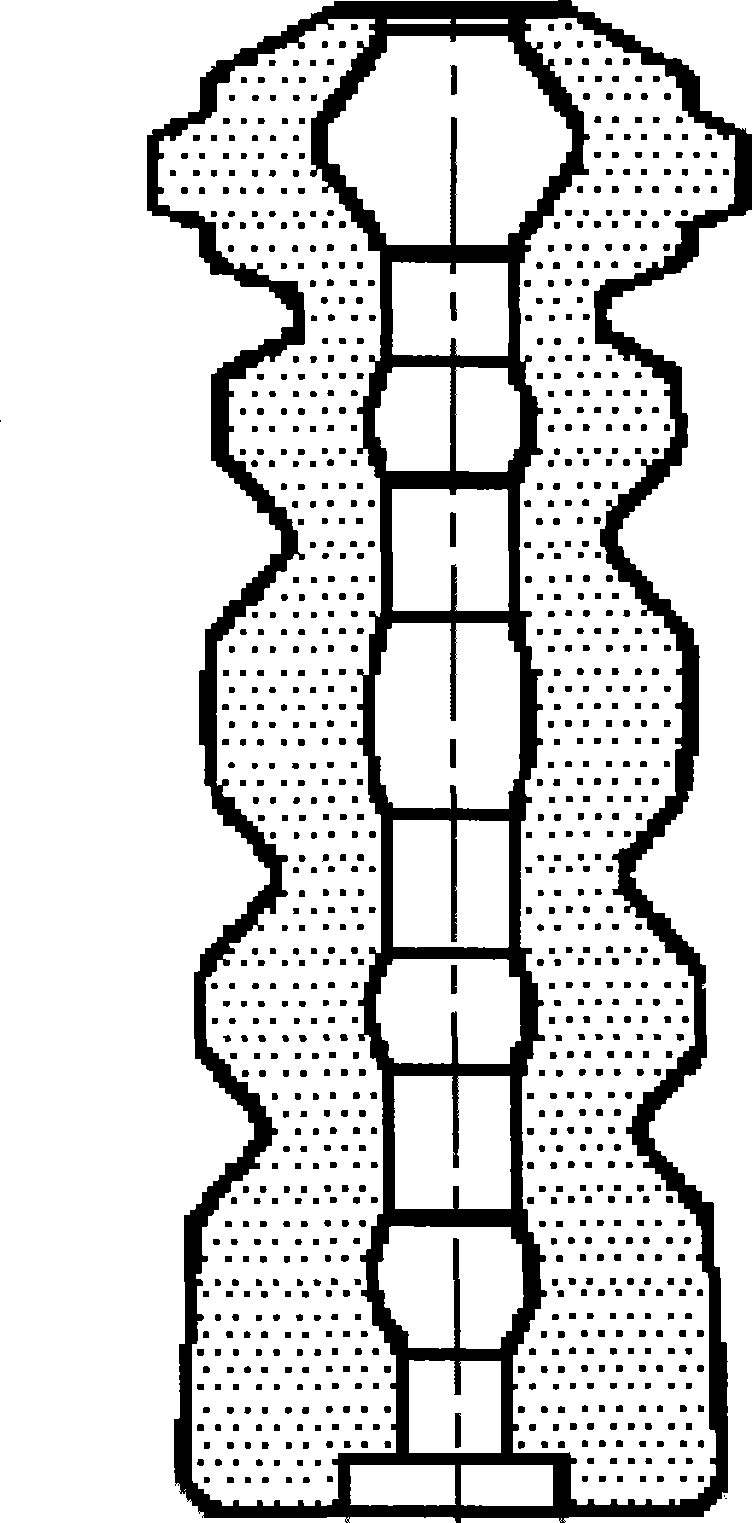

Image

Examples

Embodiment 1

[0034] Polyethylene adipate with a molecular weight of 2000 reacts with PPDI at 90-110°C to obtain a prepolymer with an NCO content of 6.2%. The main expansion agent is polyethylene adipate, and the foaming agent is water , tertiary amine catalysts, and anionic surfactants account for 3% of the total.

[0035] Using a low-pressure foaming machine, mix the prepolymer and the expansion agent according to the ratio of the isocyanate index to 100%, inject the reaction material liquid into the mold at 110°C, demould after 30 minutes, and post-cure at 110°C for 24hrs.

[0036] The test pieces and products prepared in this example were placed at room temperature for one week, and then their dynamic fatigue performance, static compression set performance and ball resilience were measured.

[0037] The test results are shown in Table 1.

Embodiment 2

[0039] Polycaprolactone with a molecular weight of 2000 and PPDI are reacted at 90-110°C to obtain a prepolymer with an NCO content of 8.50%. The extender is mainly polyadipate, and the foaming agent is water and tertiary amine Catalysts and anionic surfactants account for 3% of the total.

[0040] Using a low-pressure foaming machine, mix the prepolymer and the expansion agent according to the ratio of the isocyanate index to 100%, inject the reaction material liquid into the mold at 110°C, demould after 30 minutes, and post-cure at 110°C for 24hrs.

[0041] The test pieces and products prepared in this example were placed at room temperature for one week, and then their dynamic fatigue performance, static compression set performance and ball resilience were measured.

[0042] The test results are shown in Table 1.

[0043] Table 1. Comparative examples 1-2 and the product physical property test result of embodiment 12

[0044] project Comparative Example 1 Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com