Fully-assembled steel-structure wading basic platform

A basic platform, steel structure technology, applied in water conservancy projects, bridge forms, marine engineering and other directions, can solve the problems of special structure, difficult construction, large engineering investment, etc., to achieve mature technical conditions, quality and safety controllable, engineering investment The effect of the province

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

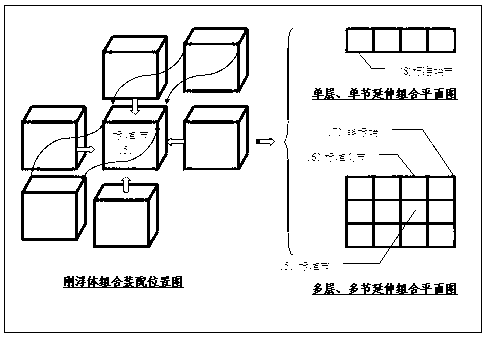

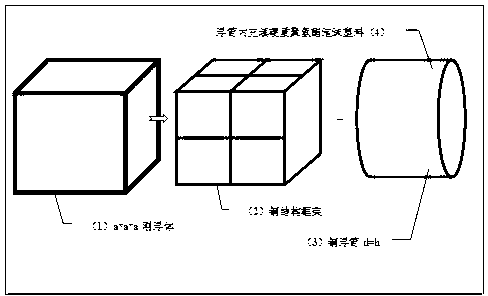

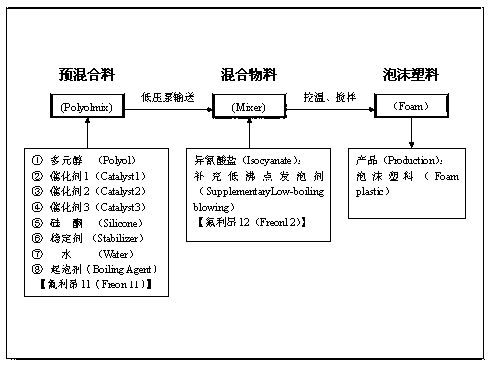

Method used

Image

Examples

Embodiment example 1

[0039] Implementation case 1: In the reservoir area formed by the construction of high-dam hydropower stations, the land terrain is usually high mountains and steep slopes; under normal circumstances, the water level of the reservoir area operates between the flood limit water level and the design high level, and the large fluctuation of water level is its inherent hydrological Features: The annual water level of the reservoir area in front of the dam varies greatly, with annual water level differences ranging from tens of meters to hundreds of meters, and the daily water level variation is relatively small; the river section at the end of the reservoir is similar to a natural river, with large annual water level changes , the daily water level also fluctuates greatly, affected by the discharge flow of the power station, the daily water level difference can reach several meters. To build various types of docks and other water-facing infrastructure or water-based infrastructure...

Embodiment example 2

[0040] Implementation case 2: In a natural lake with natural climate regulation function and protected by local regulations, although the land terrain is gentle, it is mostly tidal flats and swamps, the front and side beaches are long, and the water depth is insufficient; generally, the water level in the lake area is within the statutory It operates between the lowest operating water level and the highest flood control limit water level, and the water level does not change much, and is subject to strict human control. The construction of water-facing infrastructure or water-based infrastructure in the above-mentioned lake areas may encounter problems such as low foundation bearing capacity, deep soft foundation, insufficient water depth, and water environment protection. A large amount of money needs to be invested in soft soil foundation treatment and dredging of frontier waters , to meet the usage requirements. With the present invention, since the fully assembled steel str...

Embodiment example 3

[0041] Implementation case 3: With the advancement of my country's goal of building a well-off society in an all-round way and the strategic adjustment of the economic structure, and accelerating the establishment of a long-term mechanism for expanding consumer demand, the yacht industry, a high-end consumer that integrates water leisure and entertainment, will be affected. The preferential treatment or support of the national industrial policy has achieved rapid development; the yacht marina, as an indispensable supporting facility for the industry, will also develop synchronously. The present invention can tailor an integrated solution according to the nature, scale, use, and environmental conditions of the water and land areas of the proposed yacht wharf; popularize and develop standardized yacht wharves, which can achieve economical and intensive use of port coastline resources and standardized management. The purpose is to achieve resource conservation, environmental friend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com