Preparation method of compound enzyme preparation for promoting production of methane from kitchen waste through anaerobic fermentation

A technology of kitchen waste and compound enzyme preparation, which is used in fermentation, waste fuel and other directions to achieve the effect of promoting fast, stable operation and efficient hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

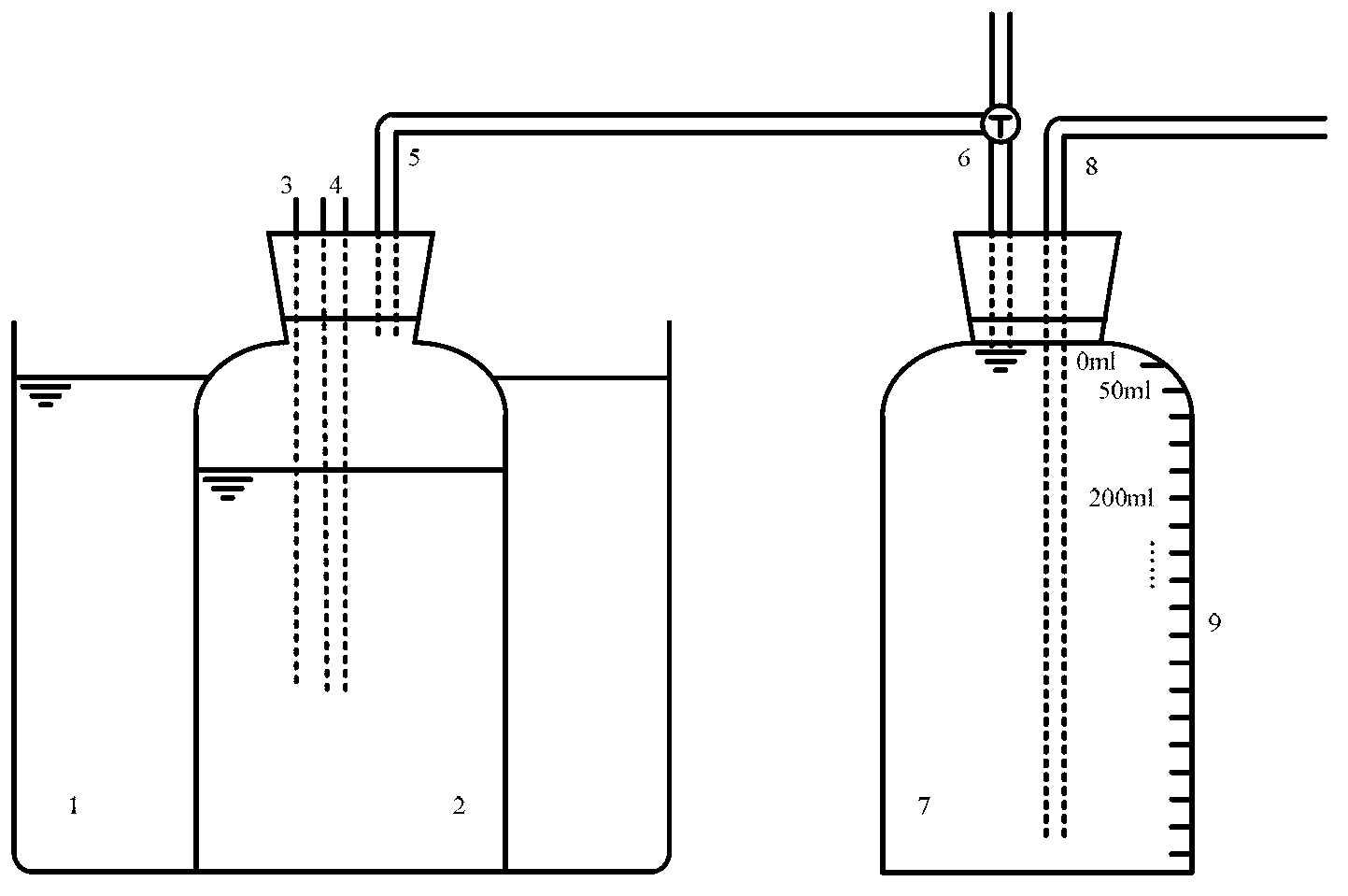

Method used

Image

Examples

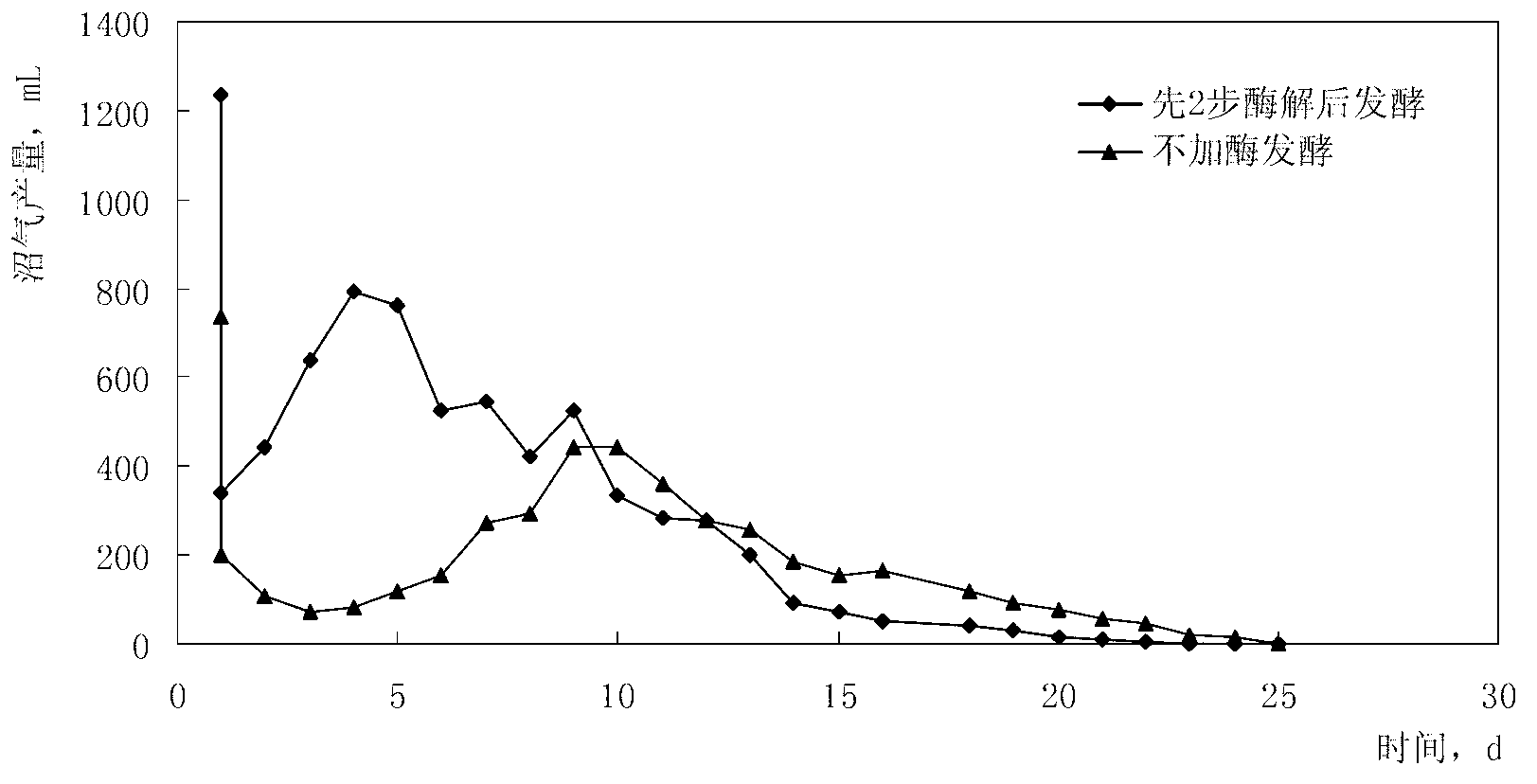

Embodiment 1

[0022] Take 50 g of the kitchen waste with a grease content of 4.5%, sorted, pulverized and homogenized, and carry out the following two groups of experiments according to the compound enzyme preparation formula 1:

[0023] Experimental group I: first add lipase to enzymatically hydrolyze the oil in the kitchen waste. Add lipase according to the amount of 180 U per gram of dry matter of the kitchen waste biomass, adjust the pH value to 6.5, place on a shaker at 100 rpm, keep a constant temperature of 40°C, and perform enzymatic hydrolysis for 36 hours.

[0024] Then add liquefaction enzyme, glucoamylase, cellulase, etc. to enzymatically hydrolyze other biomass components in kitchen waste. Add liquefaction enzyme, glucoamylase, and cellulase according to the amount of 8U, 150U, and 50U per gram of dry matter of the kitchen waste biomass, adjust the pH value to 5.5, place it on a shaker at 80-120 rpm, and keep it at 60°C Constant temperature, enzymatic hydrolysis time 4h.

[0...

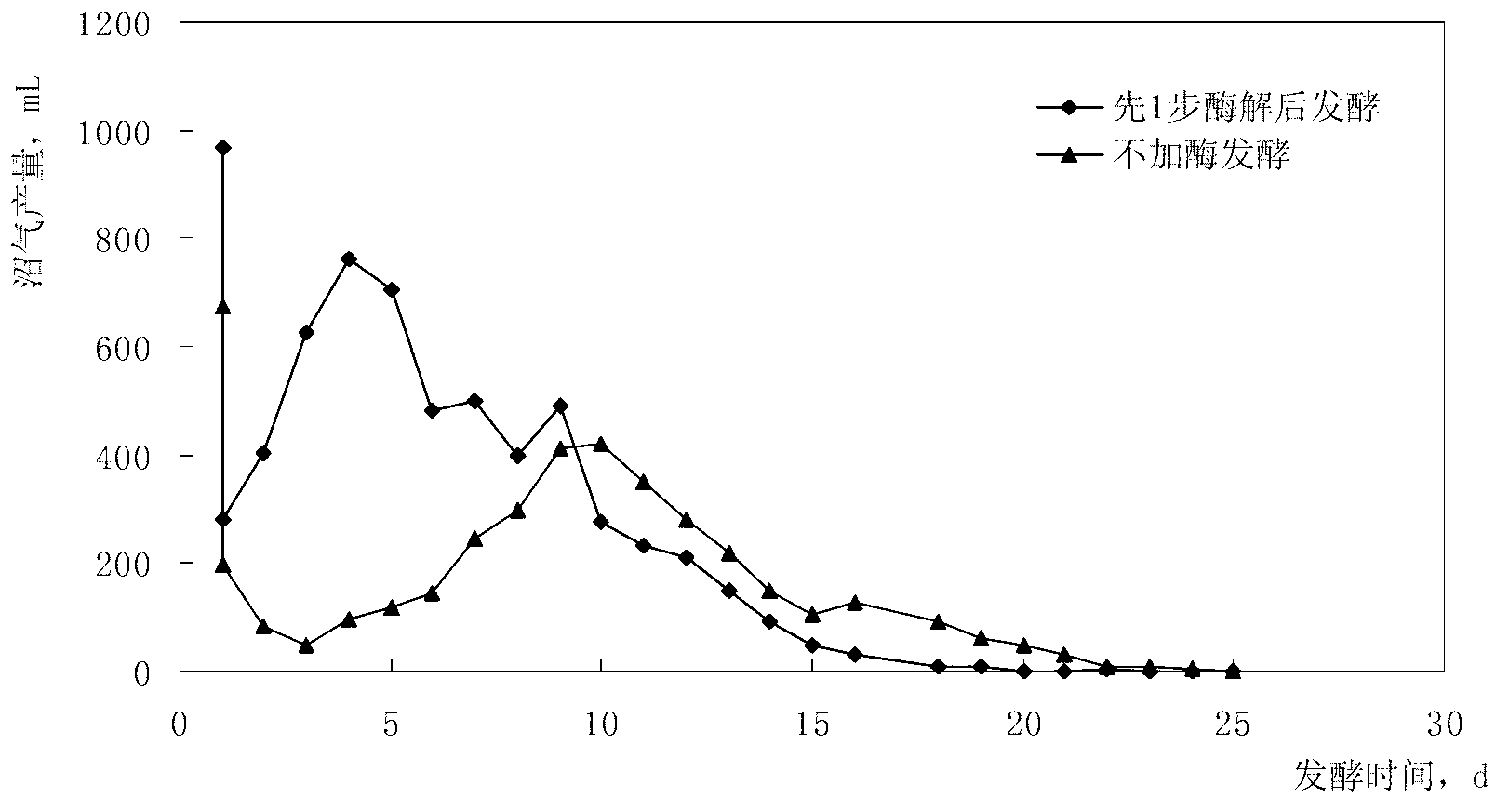

Embodiment 2

[0031] Take 0.5% oil content, sorted, pulverized and homogenized kitchen waste 50g each, according to the compound enzyme preparation formula 2, carry out the following 2 groups of experiments:

[0032] Experimental group I: first add liquefaction enzyme, glucoamylase, cellulase, etc. to enzymatically hydrolyze the biomass components in kitchen waste, and then perform anaerobic fermentation to produce biogas. Add liquefaction enzyme, glucoamylase, and cellulase according to the amount of 8U, 150U, and 50U per gram of dry matter of the kitchen waste biomass, adjust the pH value to 5.5, place it on a shaker at 80-120 rpm, and keep it at 60°C Constant temperature, enzymatic hydrolysis time 4h. Then add 200g of biogas fermentation anaerobic sludge cultivated by the laboratory to the sample after enzymolysis as inoculum, add 1L laboratory-made constant temperature anaerobic fermentation device together, add water to 750mL, mix well, and keep the fermentation temperature at 35°C. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com