Method for industrially producing grouper growth hormone recombination gene protein

A growth hormone and recombinant gene technology, applied in the field of industrial production of grouper growth hormone recombinant gene protein, can solve the problems of low yield, long time consumption, high cost, etc., achieve high yield, reduce production cost, and promote healthy growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

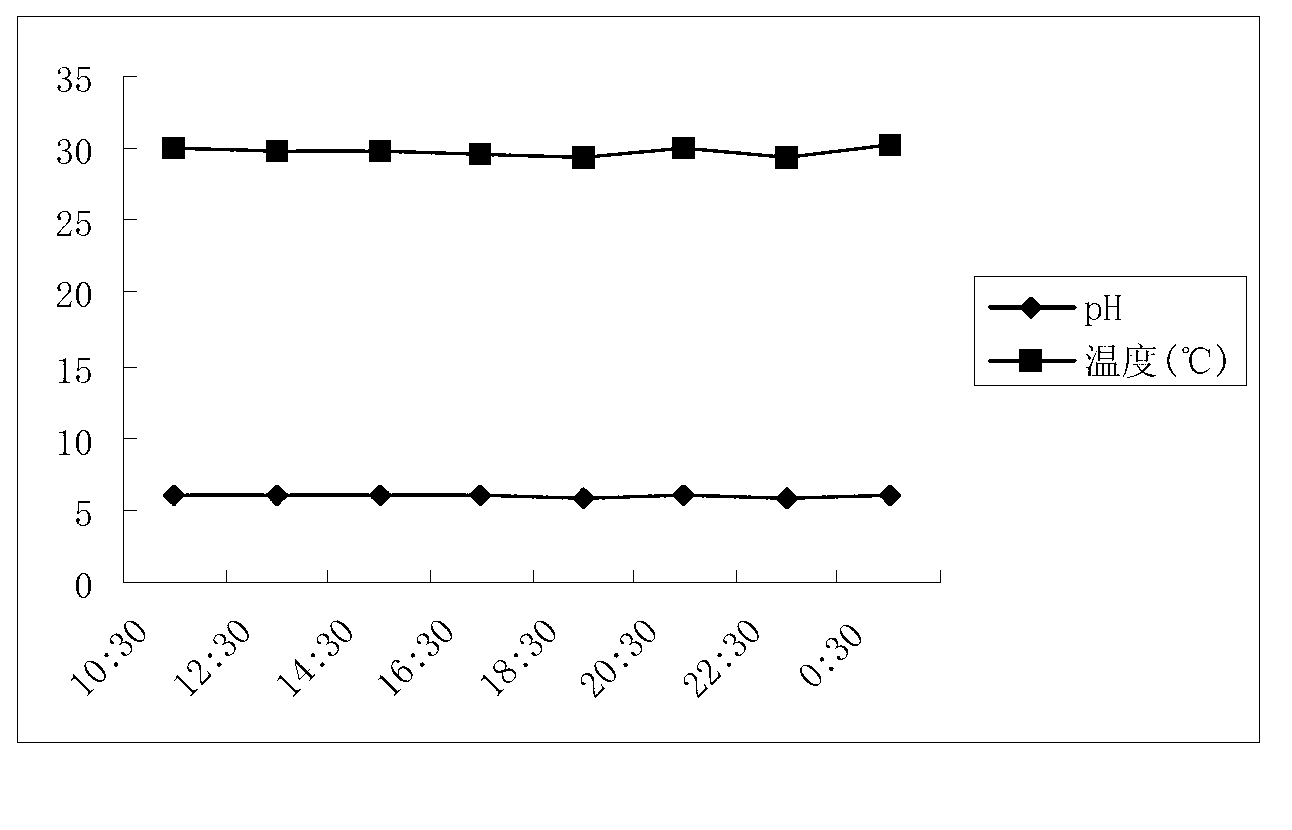

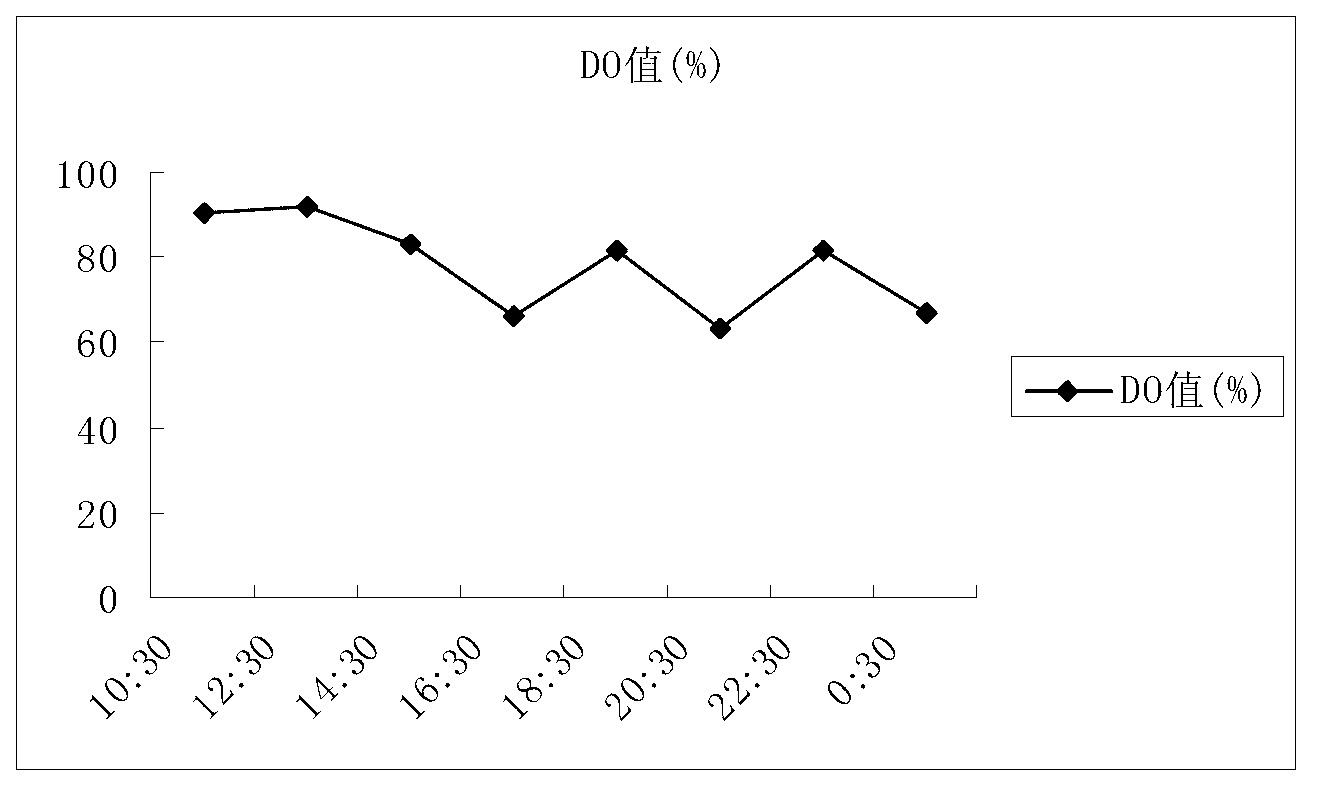

[0043] Obtain grouper growth hormone recombinant protein according to the above steps, using a 50L self-controlled tank, wherein the fermentation conditions are controlled as temperature 28°C, pH 5.5, dissolved oxygen 30%, and fermentation time 90h; the fermentation medium in the shake flask culture The volume is 30L, and the inoculum size is 1.5L; the methanol by volume accounts for 0.55% of the fermentation broth volume.

Embodiment 2

[0045] According to the above steps, the recombinant protein of grouper growth hormone was obtained, using a 50L self-controlled tank, wherein the fermentation conditions were controlled as temperature 29.5°C, pH 6.0, dissolved oxygen 40%, and fermentation time 80h; the fermentation medium in the shake flask culture The volume of the methanol is 30L, and the inoculum size is 1.8L; the volume of the methanol accounts for 0.7% of the fermentation broth volume.

Embodiment 3

[0047] According to the above steps, the recombinant protein of grouper growth hormone was obtained, using a 100L self-controlled tank, wherein the fermentation conditions were controlled as temperature 31.5°C, pH 6.5, dissolved oxygen 40%, and fermentation time 90h; the fermentation medium in the shake flask culture The volume of the methanol is 50L, and the inoculum size is 3.0L; the volume of the methanol accounts for 0.55% of the fermentation broth volume.

[0048] Test results:

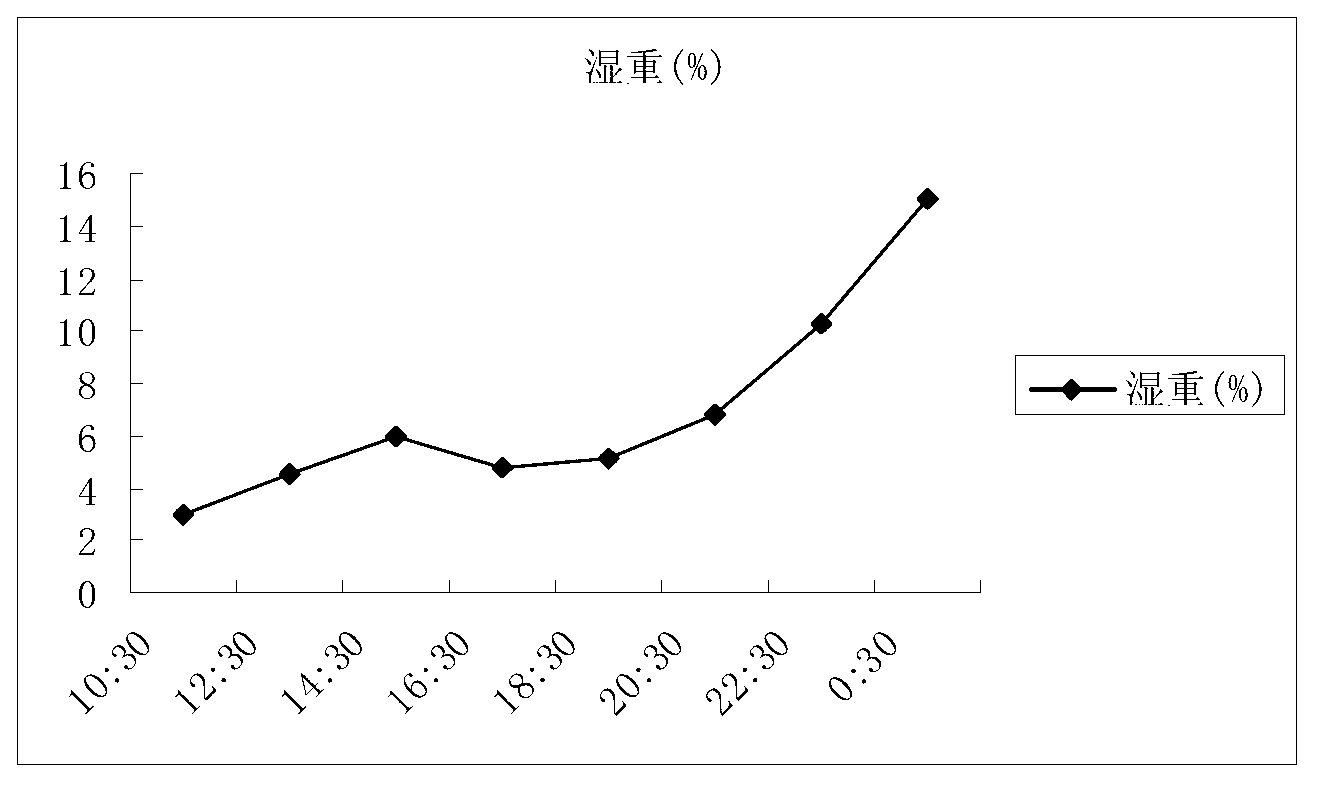

[0049] The wet weight of the strains in the fermentation broth was detected, and the protein expression of the target protein in Examples 1-3 was detected by Western Blot and SDS-PAGE polyacrylamide gel electrophoresis. The results are shown in Table 1.

[0050] Table 1: Wet weight and gGH content of strains

[0051] group 1 2 3 Wet weight of bacteria ≤20.75% 59-59.75% ≤30.15% gGH (g / L) ≤0.5 1.5-2.0 ≤0.75

[0052] Qualitative and quantitative detection of reco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com