Preparation method of fucoxanthin

A fucoxanthin and xanthin technology, applied in the direction of organic chemistry, can solve the problem of low purity, failure to obtain high-purity fucoxanthin, failure to obtain fucoxanthin and high-value development of fucoxanthin series products Application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Extraction of raw materials: Take 1 kg of kelp, wash it, dry it in a cool place, add 5 L of methanol, extract it ultrasonically for 30 minutes, filter, extract twice in the same way, combine the extracts, concentrate under reduced pressure, and obtain fucoxanthin extract paste;

[0031] (2) Preliminary separation and purification: use macroporous adsorption resin for column chromatography, elute with aqueous solution, 30% ethanol aqueous solution, 60% ethanol aqueous solution, and 90% ethanol aqueous solution, collect the eluted part of 90% ethanol aqueous solution, concentrate and dry , obtain 260 mg of crude product of fucoxanthin, content 25%;

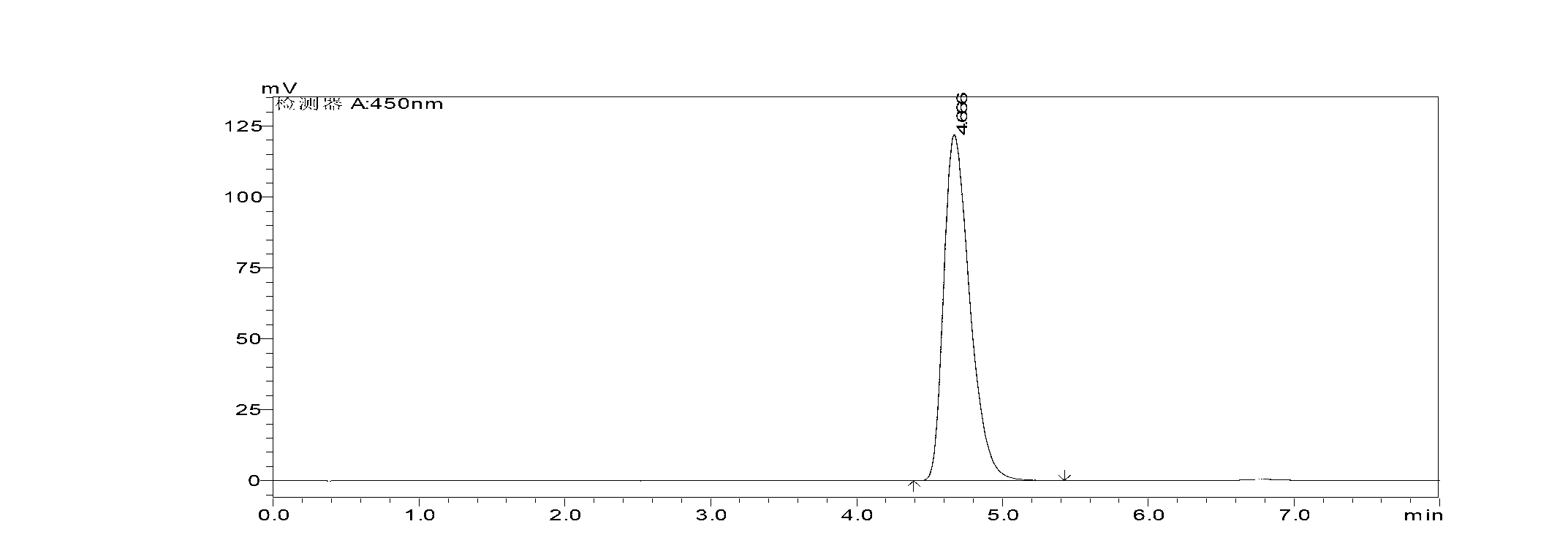

[0032] (3) Fucoxanthin refining:

[0033] a) Preparation of raw materials: the crude product of fucoxanthin is prepared into a 5 mg / ml solution;

[0034] b) Instrument: semi-preparative high performance liquid chromatography;

[0035] c) Chromatographic conditions: the semi-preparative chromatographic column is a C8 co...

Embodiment 2

[0039] 1) Extraction of raw materials: Take 1 kg of kelp, wash it, dry it in a cool place, add 5 L of ethanol, extract it ultrasonically for 60 minutes, filter, extract twice in the same way, combine the extracts, concentrate under reduced pressure, and obtain fucoxanthin extract ;

[0040] 2) Preliminary separation and purification: use macroporous adsorption resin for column chromatography, elute with aqueous solution, 30% ethanol aqueous solution, 60% ethanol aqueous solution, 80% ethanol aqueous solution, 100% ethanol aqueous solution, collect 100% ethanol aqueous solution for elution part, concentrated and dried to obtain 150 mg of crude fucoxanthin, with a content of 53%;

[0041] 3) Refined fucoxanthin:

[0042] a) Preparation of raw materials: prepare the crude product of fucoxanthin into a 5 mg / mL solution;

[0043] b) Instrument: semi-preparative high performance liquid chromatography;

[0044] c) Chromatographic conditions: the semi-preparative chromatographic co...

Embodiment 3

[0048] 1) Extraction of raw materials: Take 1 kg of kelp, wash it, dry it in a cool place, add 5 L of acetone, extract it ultrasonically for 30 minutes, filter, extract twice in the same way, combine the extracts, concentrate under reduced pressure, and obtain fucoxanthin extract ;

[0049] 2) Preliminary separation and purification: use silica gel column chromatography, elute with dichloromethane-methanol (50:1, 25:1, 10:1, 5:1) respectively, collect (25:1 and 10:1) The eluted part was concentrated and dried to obtain 105 mg of crude fucoxanthin with a content of 87%;

[0050] 3) Refined fucoxanthin:

[0051] a) Preparation of raw materials: prepare the crude product of fucoxanthin into a 5 mg / mL solution;

[0052] b) Instrument: semi-preparative high performance liquid chromatography;

[0053] c) Chromatographic conditions: the semi-preparative chromatographic column is a C8 column (250mm×10mm), the mobile phase system is 95% methanol aqueous solution, the flow rate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com