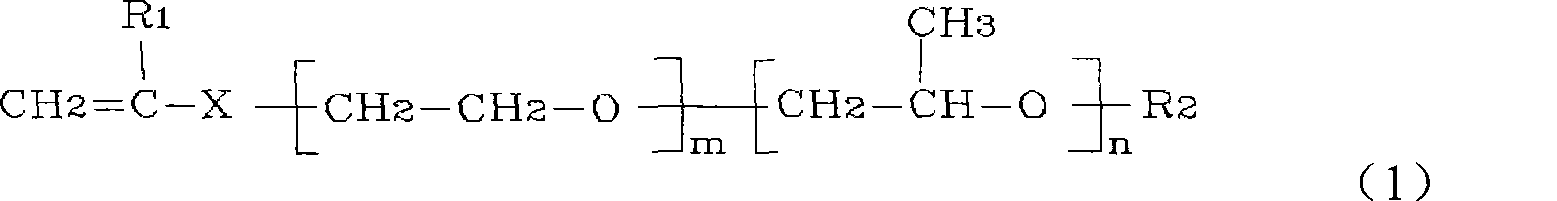

Polycarboxylate-type cement water-reducing agent and preparation method thereof

A technology of polycarboxylate and water reducer, which is applied in the field of polymers, can solve the problem of low cost performance of polycarboxylate, and achieve the effects of low cost, good slump retention and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

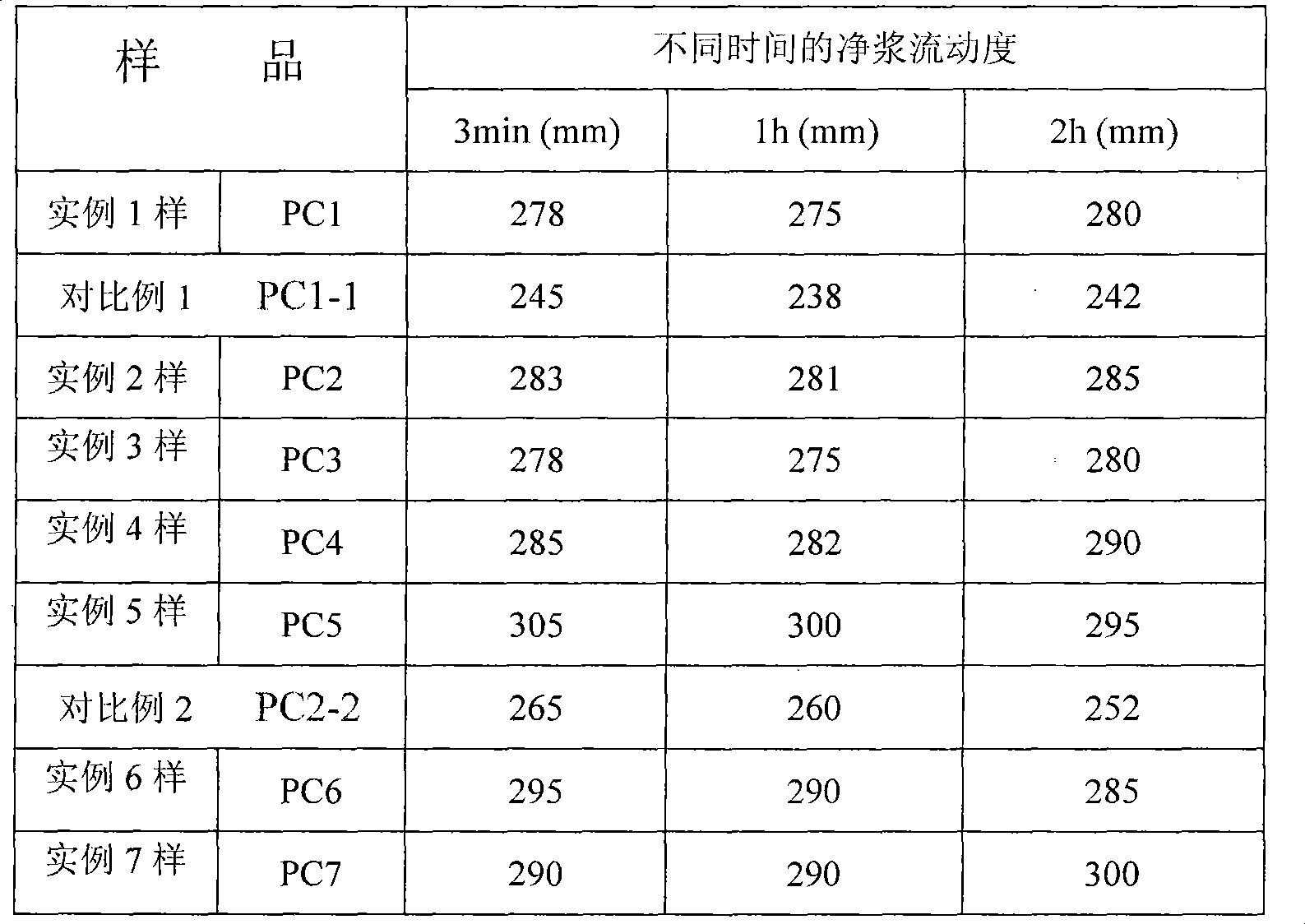

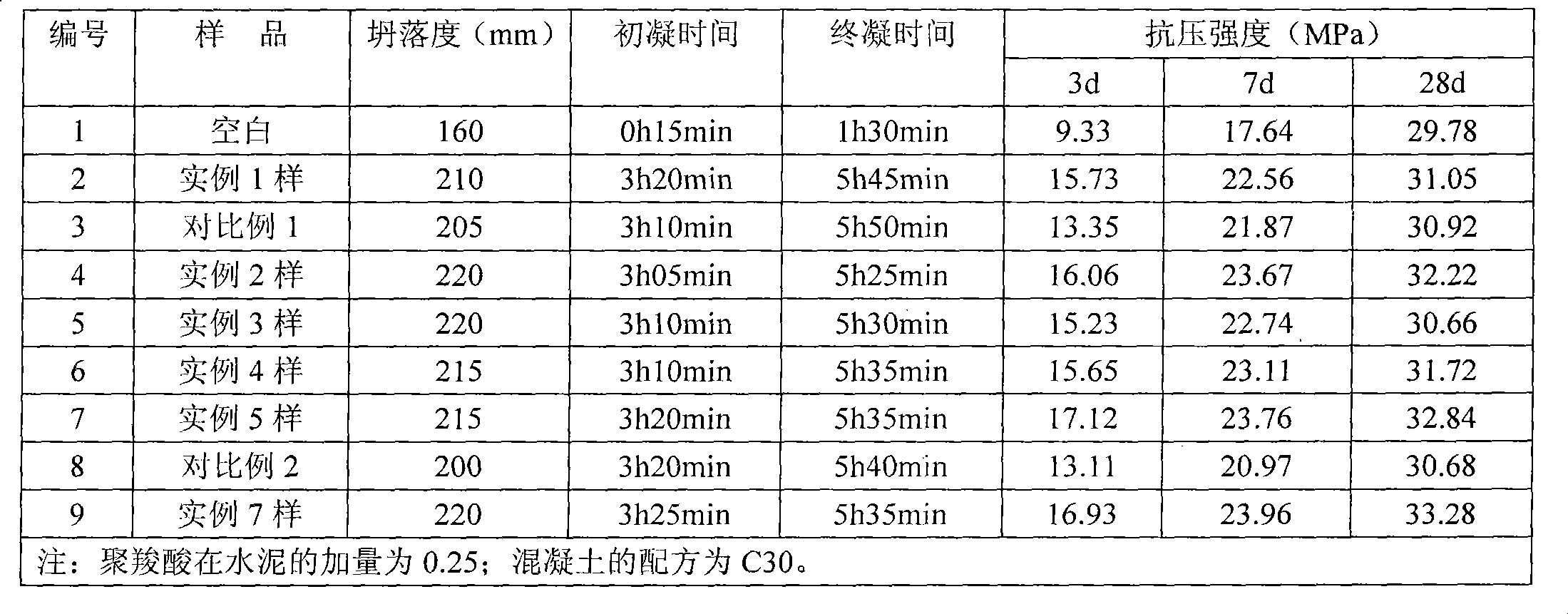

[0018] The alkenyl polyoxyethylene ether macromonomer is selected from methoxy-terminated allyl polyethylene glycol ether, molecular weight 1000, (the molar basis is 1), monomethyl maleate and N-glycine-based maleamide The molar number (relative to benchmark) of acid mixture is 1.0, and the molar percentage of maleic acid monomethyl ester and N-glycine base maleamic acid in this mixture is 35%: 65%, acrylic acid (AA) molar number ( Relative to the benchmark) is 2, ammonium persulfate is the initiator, the addition of the initiator is 2.0% of the total weight of the monomer, and the required deionized water is added according to the solid content of 35%, and the two types of monomers A and B And part of the water is used as the base material, the aqueous solution of the acrylic acid monomer and the initiator is added dropwise separately, the polymerization temperature is 75-80 ℃, and the polymerization reaction is 6.0 hours to obtain the polymer, which is neutralized with NaOH t...

Embodiment 2

[0023] The alkenyl polyoxyethylene ether macromonomer is selected from methoxy-terminated allyl polyethylene glycol ether, molecular weight 1000, (the molar basis is 1), monomethyl maleate and N-glycine-based maleamide The molar number (relative to the benchmark) of the mixture of acids is 1.0, and the molar percentages of the two in the mixture are respectively 80%: 20%, the molar number of acrylic acid (AA) (relative to the benchmark) is 2.0, and ammonium persulfate is the initiator The addition amount of the initiator is 2.5% of the total weight of the monomer, and the required deionized water is added according to the solid content of 35%. The two types of monomers A and B and part of the water are used as primers. The aqueous solution of the agent was added dropwise separately, the polymerization temperature was 80-85°C, and the polymerization reaction was 5.0 hours to obtain a polymer, which was neutralized with NaOH to obtain a polycarboxylate water reducer, which was de...

Embodiment 3

[0025] Alkenyl polyoxyethylene ether macromonomer selects allyl polyethylene glycol ether, molecular weight 1000, (mole number basis is 1), the mole of the mixture of itaconate monomethyl ester and N-glycine base maleamic acid number (relative to the benchmark) is 1.0, and the molar percentages of the two are respectively 70%: 30% in the mixture, the molar number of acrylic acid (AA) (relative to the benchmark) is 2.0, ammonium persulfate is the initiator, and the The addition amount is 2.5% of the total weight of the monomers, and the required deionized water is added according to the solid content of 35%. The two types of monomers A and B and part of the water are used as primers. Add dropwise, the polymerization temperature is 80-85°C, and the polymerization reaction takes 5.0 hours to obtain a polymer, which is neutralized with NaOH to obtain a polycarboxylate water reducer, which is designated as PC3. See Table 1 for the relationship between the slurry fluidity of cement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com